An anti-flanging slitting process and cutter suitable for high-quality battery aluminum foil

A high-quality, aluminum foil technology, applied in metal processing and other directions, can solve the problems of fatigue and heat at the tangent point, unsharp knife edge, powder loss and burrs, etc., to improve the durability, reduce production costs and material loss, and facilitate processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

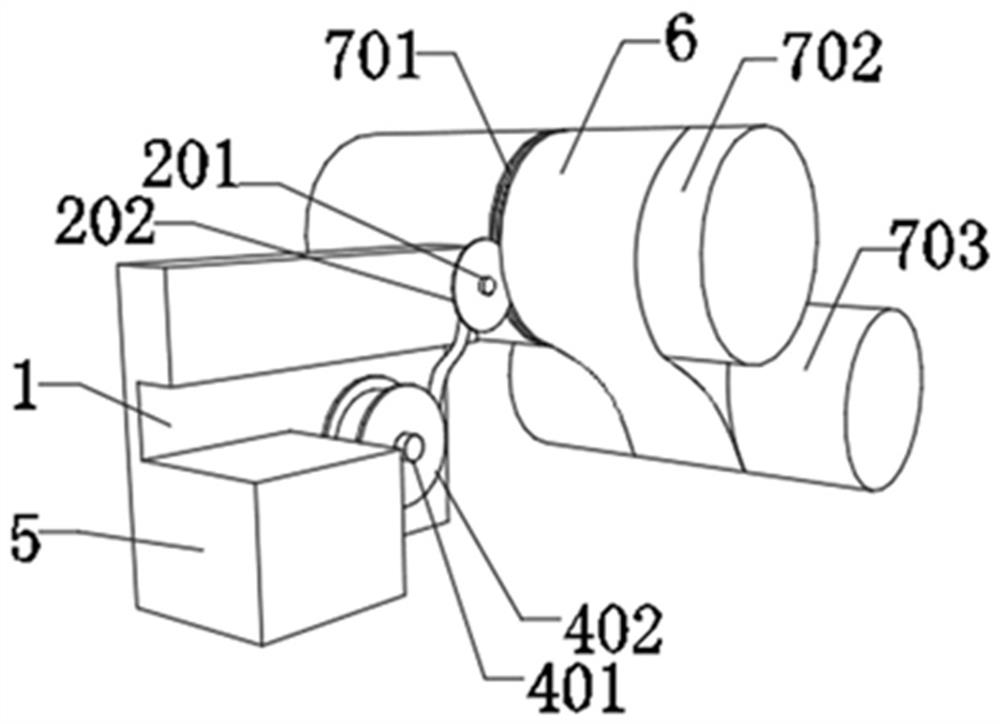

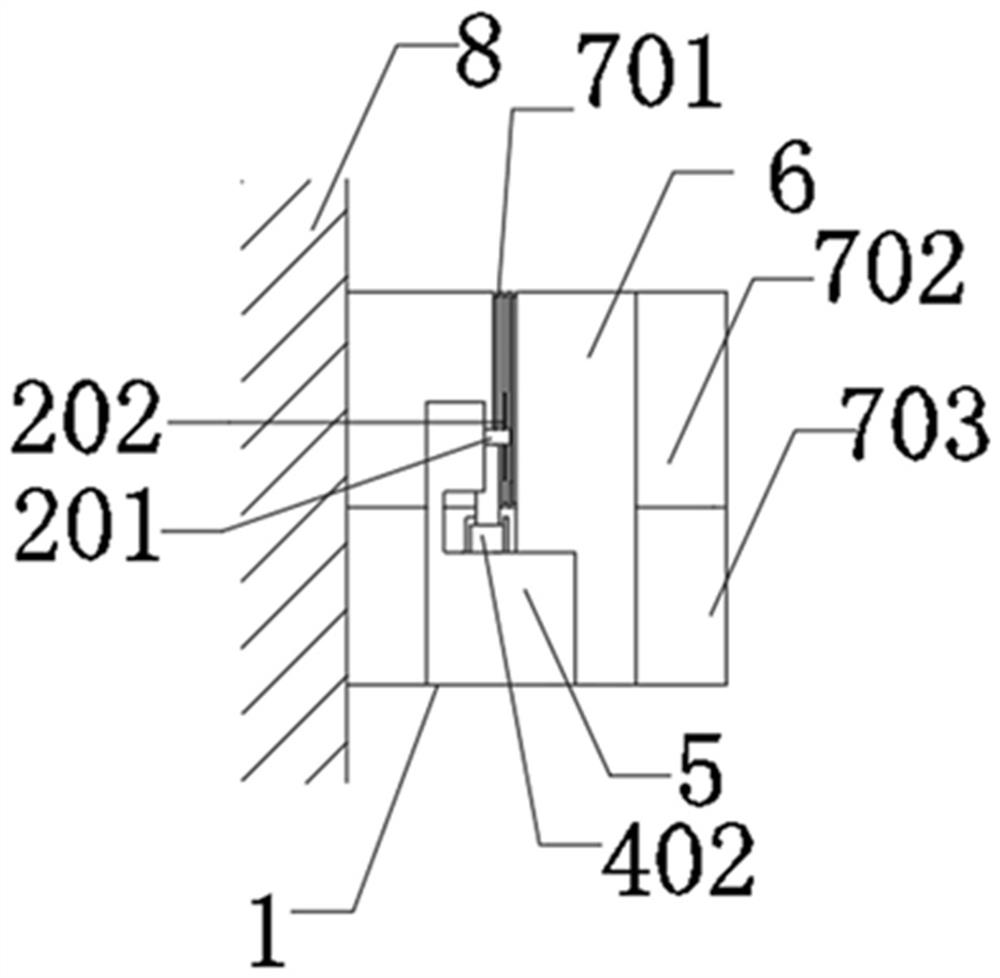

[0030] like Figure 1-Figure 5 , in this case, the anti-flanging slitting device suitable for high-quality battery aluminum foil includes a machine base 1, a cutting device 2, a deceleration device, a leveling device, an aluminum foil collection box 5 and an aluminum foil transmission device. The upper part of the base 1 is provided with a driving motor 101, and the middle part is provided with a deceleration device, the cutting device 2 is connected to the driving motor 101, and the ceramic cutting knife 202 is arranged on the side of the No. The angle between the ceramic cutting knife 202 and the cut surface of the aluminum foil is less than 45°, which effectively avoids the probability of cutting and flanging the aluminum foil. The shaft 301 and the No. 3 rotating shaft decelerate the No. 3 rotating shaft 401 by virtue of the difference in the rotation circumference. The flattening turntable 402 is fixedly installed on the lower side of the machine base 1, and the aluminum ...

Embodiment 2

[0035] like Figure 1-Figure 5 , in this case, the anti-flanging slitting device suitable for high-quality battery aluminum foil includes a machine base 1, a cutting device 2, a deceleration device, a leveling device, an aluminum foil collection box 5 and an aluminum foil transmission device. The upper part of the base 1 is provided with a driving motor 101, and the middle part is provided with a deceleration device, the cutting device 2 is connected to the driving motor 101, and the ceramic cutting knife 202 is arranged on the side of the No. The angle between the ceramic cutting knife 202 and the cut surface of the aluminum foil is less than 45°, which effectively avoids the probability of cutting and flanging the aluminum foil. The shaft 301 and the No. 3 rotating shaft decelerate the No. 3 rotating shaft 401 by virtue of the difference in the rotation circumference. The flattening turntable 402 is fixedly installed on the lower side of the machine base 1, and the aluminum ...

Embodiment 3

[0042] like Figure 1-Figure 5 As shown, the described method for using an anti-flanging slitting device suitable for high-quality battery aluminum foil includes the following steps:

[0043] The aluminum foil raw material 6 is transferred to the position of the ceramic cutting knife 202 through the No. 1 aluminum foil transmission wheel 702 and the No. 2 aluminum foil transmission wheel 703. The cutting angle between the ceramic cutting knife 202 and the aluminum foil cutting surface is less than 45°, and the driving motor 101 drives the No. 1 rotating shaft 201 to rotate to drive The ceramic cutting knife 202 cuts the aluminum foil raw material 6, the No. 1 linkage belt 302 and the No. 2 linkage belt 303 decelerate the leveling turntable 402, heat the leveling turntable 402 to 80 degrees Celsius to 90 degrees Celsius, the cut aluminum foil slides along the leveling turntable 402, and is leveled by heating The turntable 402 eliminates the internal stress of the aluminum foil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com