Preparation method of large-area ordered quantum dot film based on Langmuir technology

A quantum dot and large-area technology, applied in the nanometer field, can solve the problems such as the difficulty in preparing large-area highly ordered films, and achieve the effects of precise and controllable film thickness, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the features and advantages of this patent more obvious and easy to understand, the following special examples are described in detail as follows:

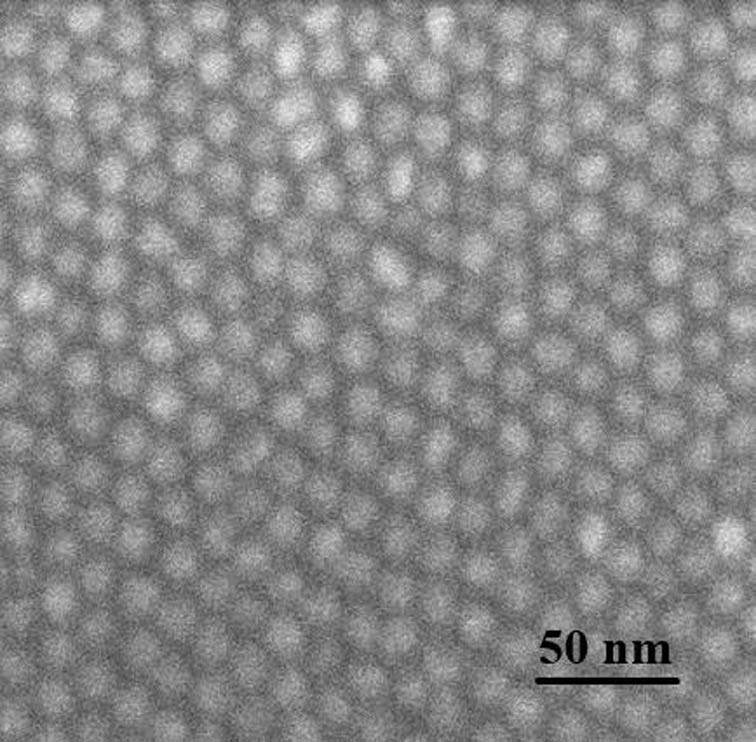

[0024] In this embodiment, CdSe quantum dots are used as the quantum dot material, and deionized water is used as the subphase.

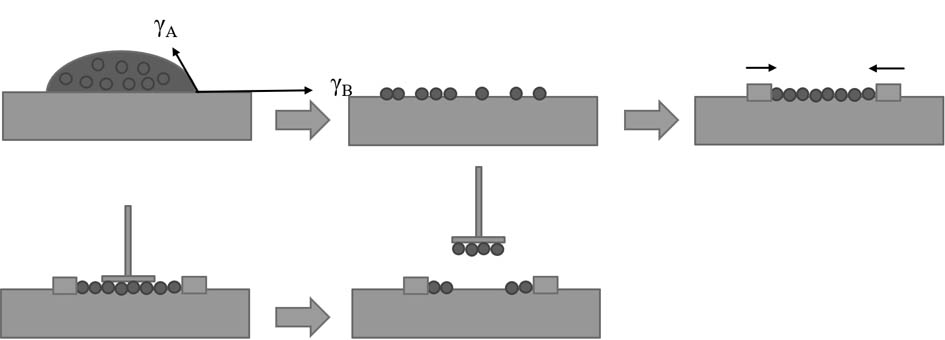

[0025] This embodiment provides a method for preparing a large-area ordered CdSe quantum dot film based on Langmuir technology, figure 1 It is a schematic flow diagram of a preferred embodiment for preparing a large-area ordered CdSe quantum dot film based on Langmuir technology, as shown in the figure, and the specific steps are:

[0026] A, disperse the quantum dots in a non-polar solution to form a quantum dot solution;

[0027] B. Add the quantum dot solution dropwise on deionized water, disperse the quantum dots on the water surface through the joint tension of water and solvent, and wait for the solvent to evaporate for 30 minutes;

[0028] C. Control the speed of the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com