Heat treatment control system and heat treatment method for steel rail welding seams

A heat treatment method and control system technology, which is applied in the rail weld heat treatment control system and the field of heat treatment, can solve the problems of low degree of automation and inaccurate temperature control, and achieve the effect of reducing errors and precise air blowing positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

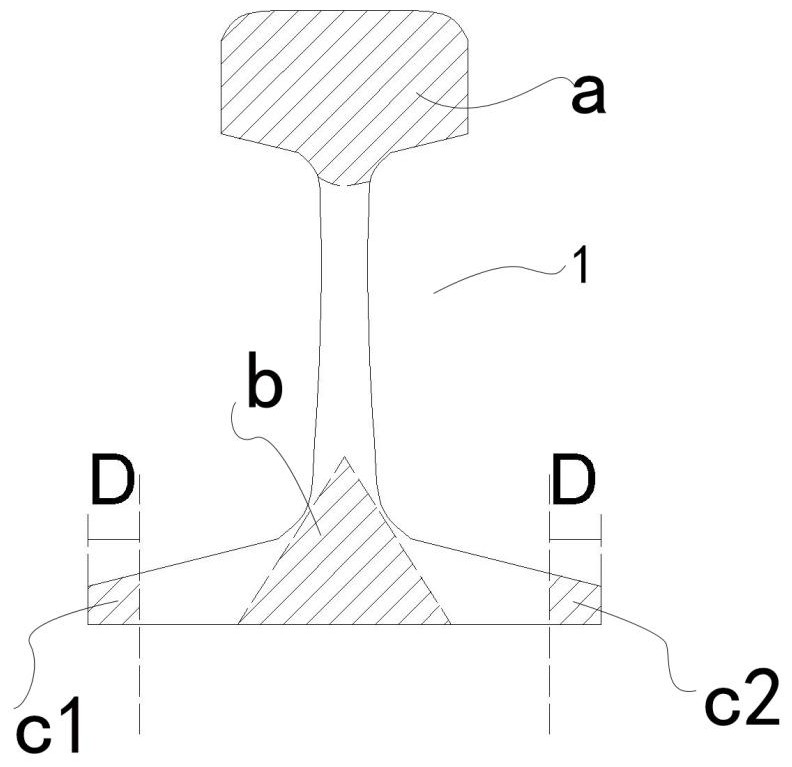

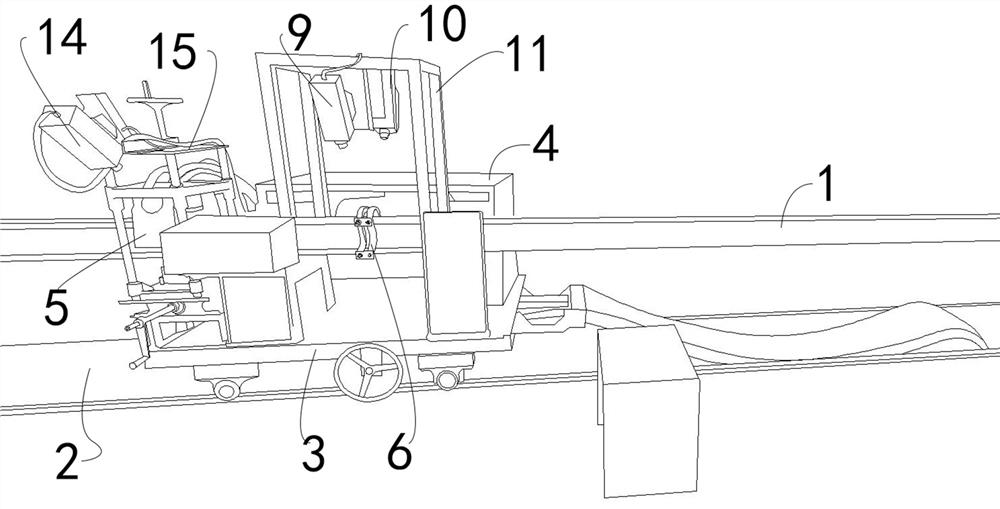

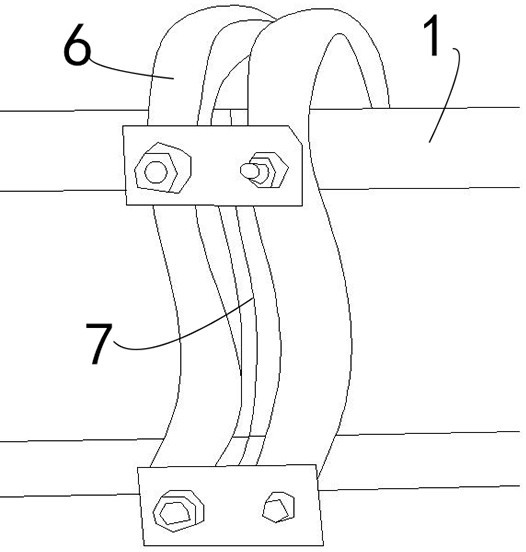

[0043] Such as figure 2 As shown, an existing rail weld heat treatment device includes a roller conveyor line 2, a running device 3, and a KGPS-III-3 type rail dual-frequency normalizing machine 4, an air spray device 5, and a normalizing device 3 are mounted on the running device 3. Coil 6, steel rail 1 is transported vertically through normalizing coil 6 and blowing device 5 through roller conveying line 2 (as image 3 , 4 , 7). Such as image 3 , 4 As shown, in this embodiment, the normalizing coil 6 includes two induction heating coils arranged in parallel, and a crack 7 for detection is left between the two induction heating coils, and heat treatment is performed when the rail weld is located at the position of the crack 7; heat treatment Finally, the running device 3 moves along the rail 1, so that the rail weld seam is positioned in the blast device 5 for blast cooling.

[0044] Such as Figure 8 Shown is the block diagram of the hardware connection relationship ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com