Sintered body for adsorption, production method therefor, and adsorption device

A manufacturing method and technology of sintered body, which are applied in separation methods, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of unsuitable adsorption fluid adsorption devices, reduced flow rate, and lack of mechanical strength of molded products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0110] In each syringe (61) with a volume of about 3ml, glass frit (filter for preventing powder from flowing out) (62a) is arranged, and the adsorption sintered bodies (20) of Examples 1 to 4 are respectively filled, and then glass frit ( 62b), as Figure 7 The pressure loss test device (60). For each of Examples 1 to 4, the adsorption when the air adjusted to 0.2 L / min by the flow meter (64) flows through the adsorption sintered body (20) was measured with a pressure gauge (KEYENCE Co., Ltd. AP-53A) (63) Use the differential pressure between sintered bodies (20);

[0111]

[0112] Instead of the sintered body (20) for adsorption, each powder body (69) of Comparative Examples 1 to 4 and Comparative Examples 1' and 2' was filled in the syringe (61), and the same method as in the previous example was used. Test method The differential pressure of each comparative example was measured.

[0113] [1-3] Test results and investigation

[0114] For example, the horizontal axis ...

Embodiment 5 and 6

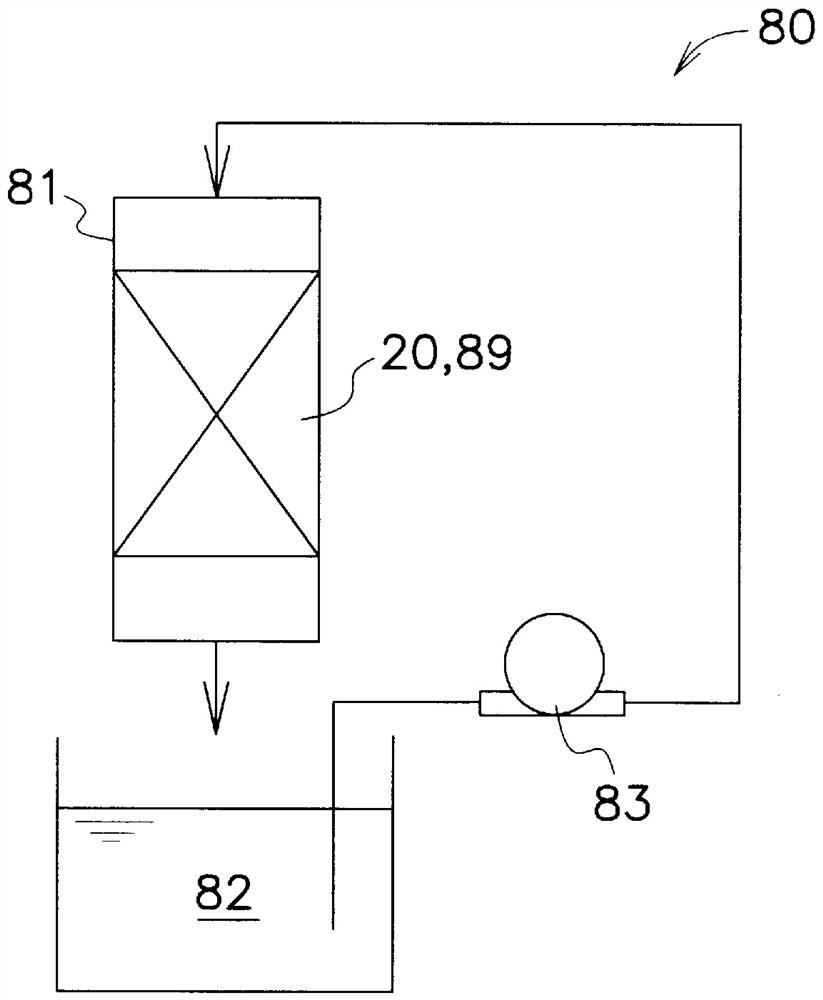

[0122] Utilize the liquid-through adsorption test device (80), for the container (81) of inner diameter 8.6mm that is filled with respectively the adsorption sintered body (20) of embodiment 5 and 6, transport and store by tube pump (83) with 3.2ml / min Concentration 1200mg / l methylene blue solution 20ml in the container (82) and make it circulate ( Figure 10 ). The circulating liquid of each 0.1ml is collected at regular intervals, and after being diluted to 100 times, the absorbance at wavelength 665nm is measured by a spectrophotometer (UV-1700 manufactured by Shimadzu Corporation). Methylene blue residual concentration.

Embodiment 5

[0130] The sintered body for adsorption (20) of Example 5 was obtained by the same method as above. Mix 0.076 parts by mass of granular activated carbon with an average diameter of about 2000 μm obtained by activating carbides of coconut shell with steam and 0.177 parts by mass of polyethylene beads with a diameter of 100 μm to obtain granular bodies (99) (comparative example 7). For large-diameter granular activated carbon with a particle diameter of about 2000 μm, the sintered body for adsorption of the present invention cannot form the voids between the resin structures so that the activated carbon can swim, and the number of particles is extremely small compared with powder. Therefore, a large number of voids without activated carbon were also formed, so in order to achieve the same conditions as in Example 5 as much as possible, polyethylene beads were used in the same amount as the polyethylene powder. A granular body (99) containing only 0.076 parts by mass of granular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com