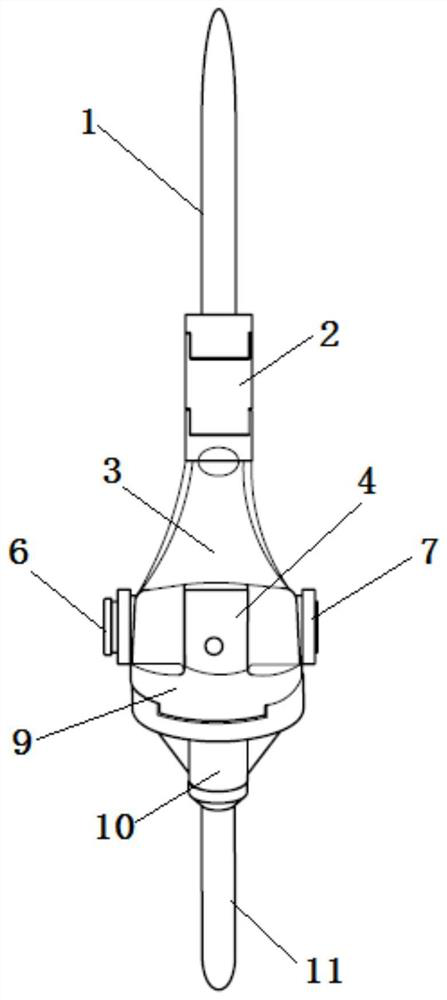

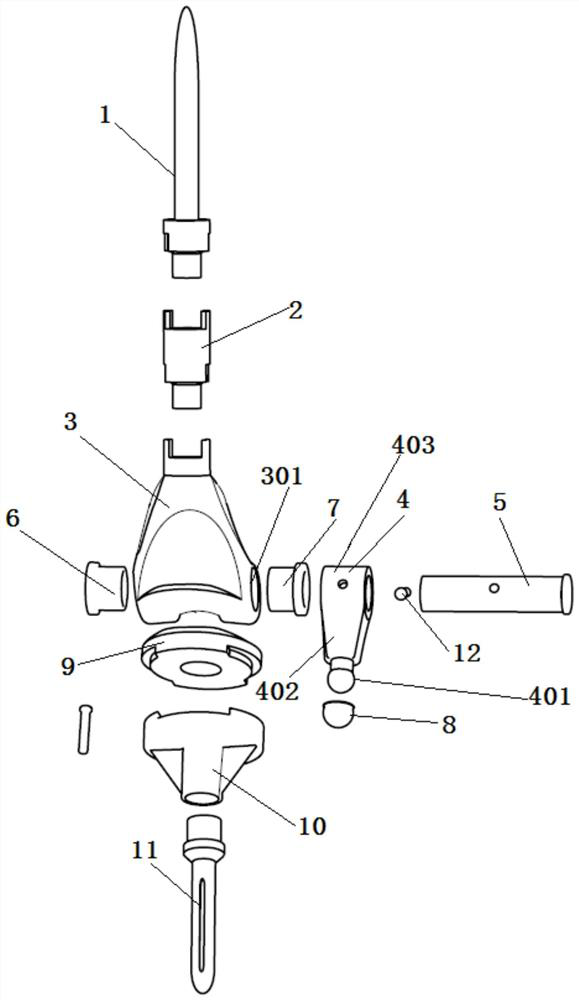

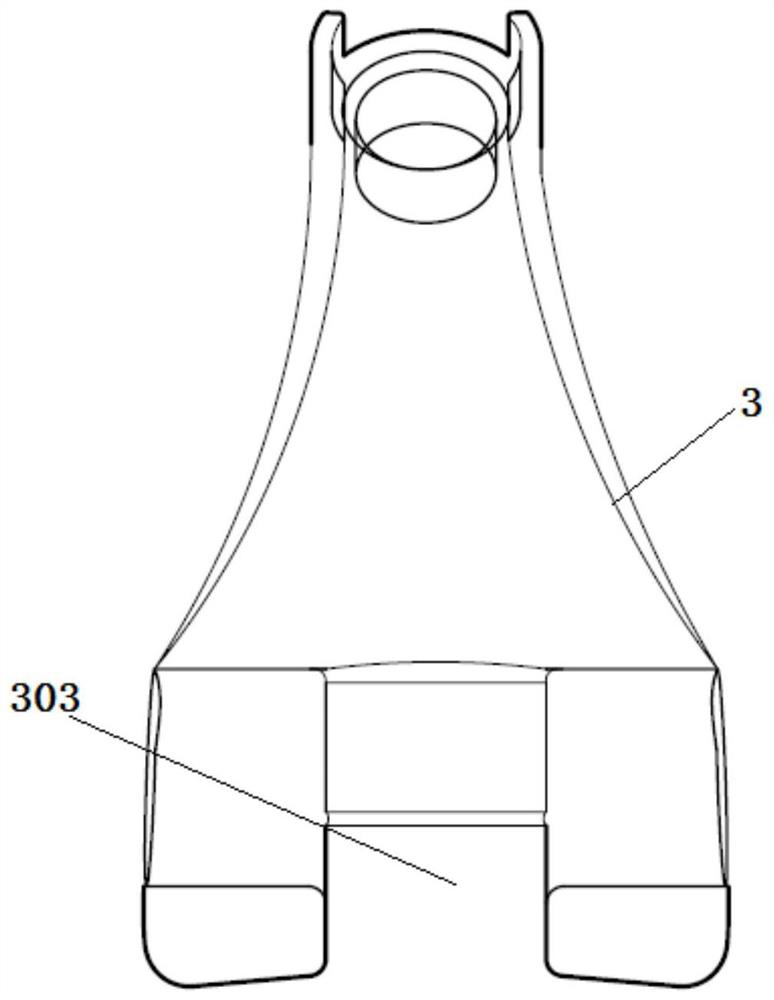

Assembled distal femur tumour type bionic prosthesis containing universal assembly

A modular, femoral technology, applied in the field of medical equipment, can solve the problems of aggravating the fracture or wear of the host bone, the mismatch of the elastic modulus of the bone, and the failure of the prosthesis, so as to reduce the risk of bone loss and avoid stress shielding. effect, the effect of reducing secondary fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The degree of polymerization of PEEK in the CFR-PEEK used in this embodiment is 105, the number average molecular weight is 34,000, the weight average molecular weight is 100,000, and the molecular weight distribution is 3.2-3.8, wherein the content of carbon fiber is 30wt%. The mechanical properties and densities are shown in Table 1.

Embodiment 2~6

[0052] The difference between Examples 2-6 and Example 1 lies in that the content of carbon fibers is different, and the specific test results are shown in Table 1.

[0053] Table 1 shows the effect of different carbon fiber contents on the mechanical properties and density of PEEK

[0054]

[0055] It can be seen from Table 1 that as the proportion of carbon fiber increases gradually, the elastic modulus and tensile strength of the prosthesis also gradually increase, and the stiffness gradually increases, but the toughness gradually decreases. When the carbon fiber content reaches 60%, the material has no plastic function at all and is very hard. This material is not suitable for making joint prostheses. Therefore, after continuous attempts, it was finally determined that the mechanical properties of 30wt% CFR-PEEK material are the most suitable for knee prosthesis, which takes into account both rigidity and toughness. In addition, the carbon fibers in the present inventi...

Embodiment 7

[0057] This embodiment is the same as Embodiment 3, wherein the content of carbon fiber is 30wt%, the degree of polymerization of PEEK is 105, the number average molecular weight is 34,000, the weight average molecular weight is 100,000, and the molecular weight distribution is 3.2-3.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com