A low-loss cutting machine

A cutting machine, low-loss technology, used in forming/shaping machines, special forming/shaping machines, manufacturing tools, etc., can solve problems such as easy scratching of human hands, easy deformation of saw teeth, and increase in production costs of enterprises. The probability of injury, the possibility of reducing the deformation, the effect of ensuring the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

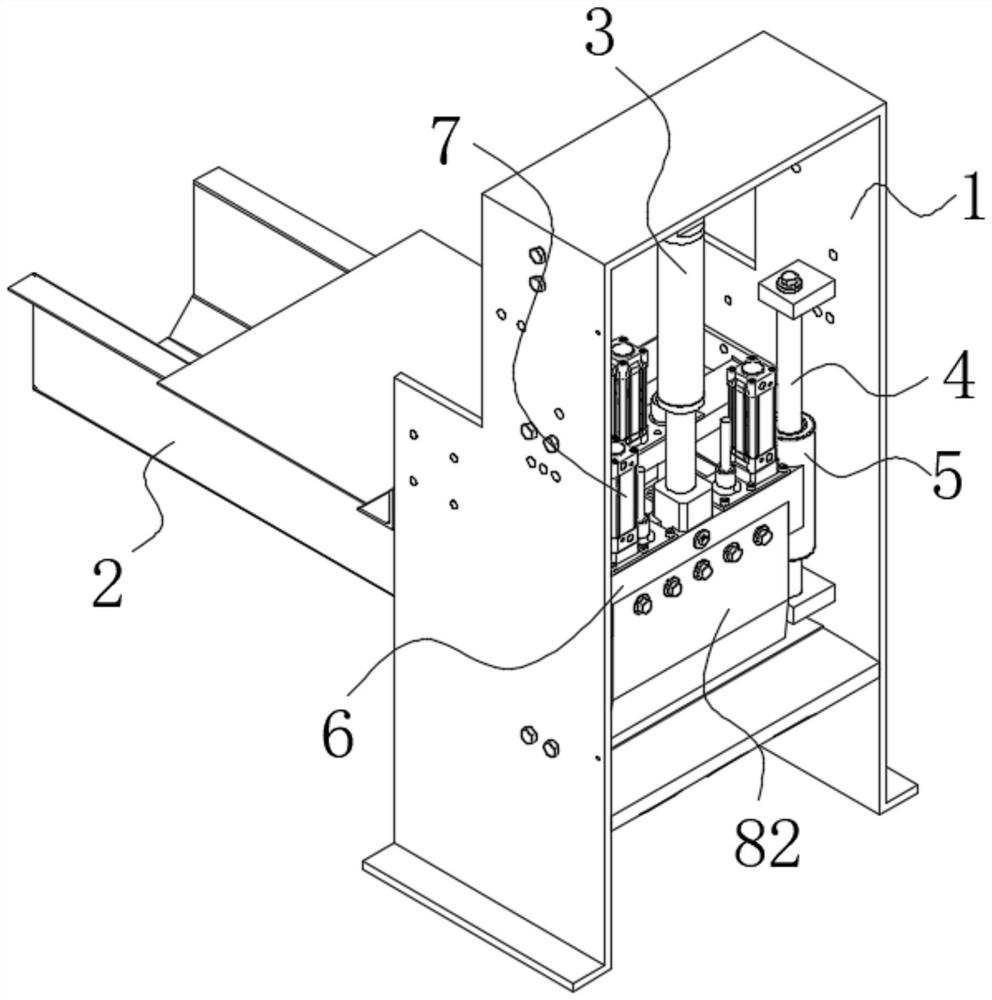

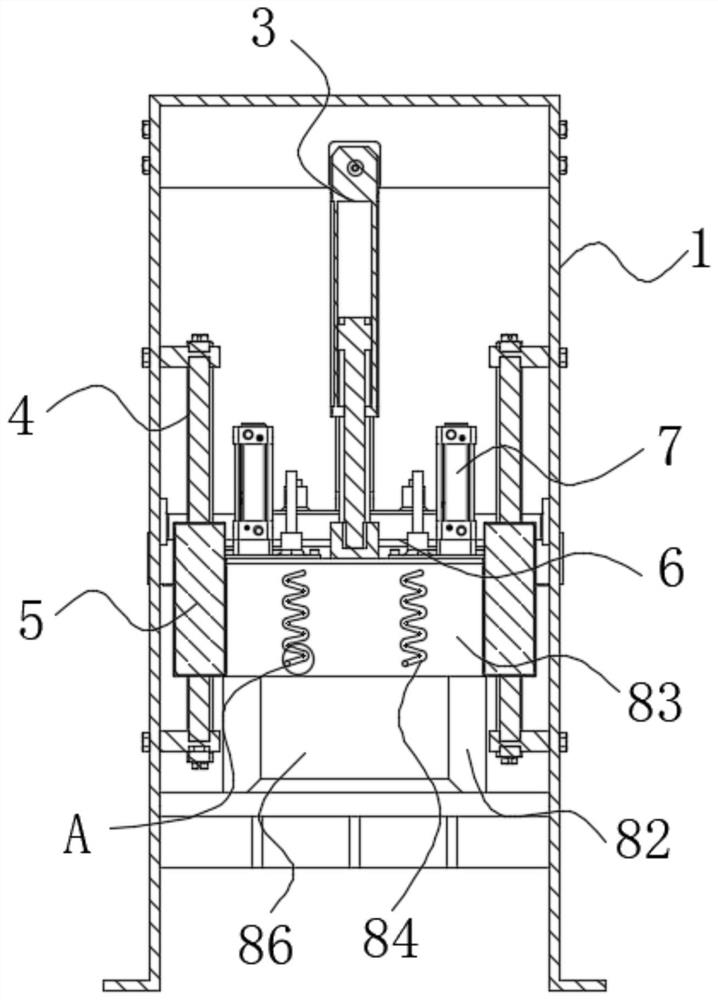

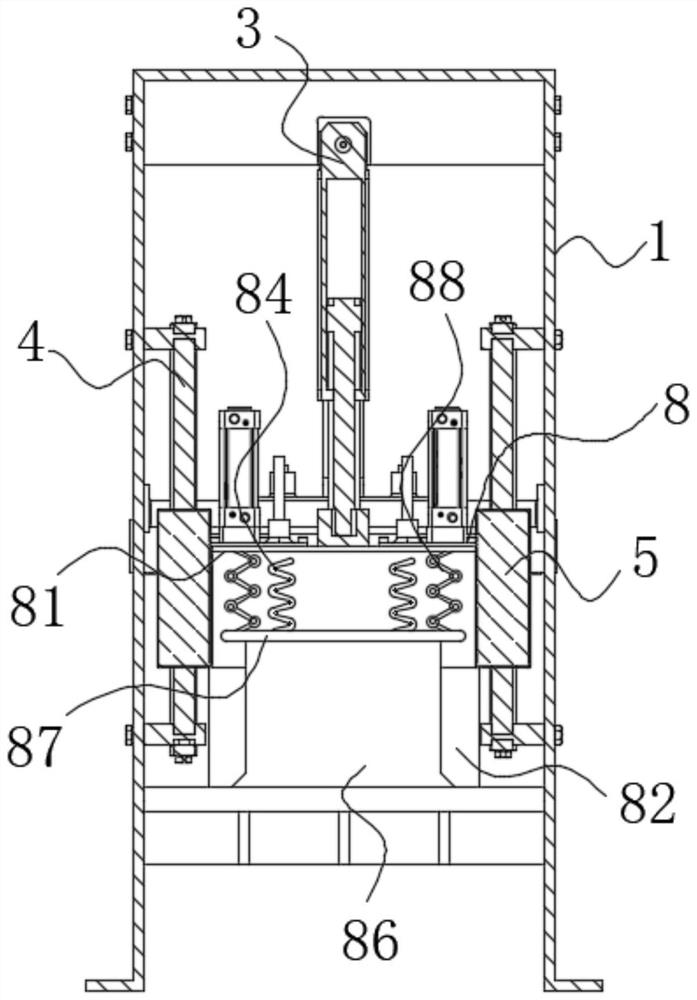

[0023] use Figure 1-Figure 7 A low-loss cutter according to an embodiment of the present invention will be described below.

[0024] like Figure 1-Figure 7As shown, a low-loss cutting machine according to the present invention includes a mounting frame 1, a conveying track 2, a hydraulic cylinder 3, a sliding rod 4, a sleeve 5, an outer plate 6, a level 7 and a cutting mechanism 8; the installation The inner lower end of the frame 1 is fixedly connected with the conveying track 2 by screws, and the inner upper wall of the mounting frame 1 is fixedly connected with a hydraulic cylinder 3; the lower end of the hydraulic cylinder 3 is slidably connected to the middle wall of the outer plate 6; The two ends of the plate 6 are fixedly connected to the inner surface of the sleeve 5; the sleeve 5 is slidably connected to the outer wall of the sliding rod 4; Levels 7 are slidably connected to both end walls of the outer plate 6 , and a cutting mechanism 8 is arranged on the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com