Intelligent concrete mortar production equipment

A concrete mortar and intelligent production technology, which is applied in the direction of clay preparation device, mixing operation control, mixing operation control device, etc., can solve the problems of long transportation time of concrete mortar, large investment in equipment, high cost, etc., and achieve automatic and effective management of batching, protection The effect of environment and precise measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] In conjunction with the accompanying drawings, the present invention is described in detail.

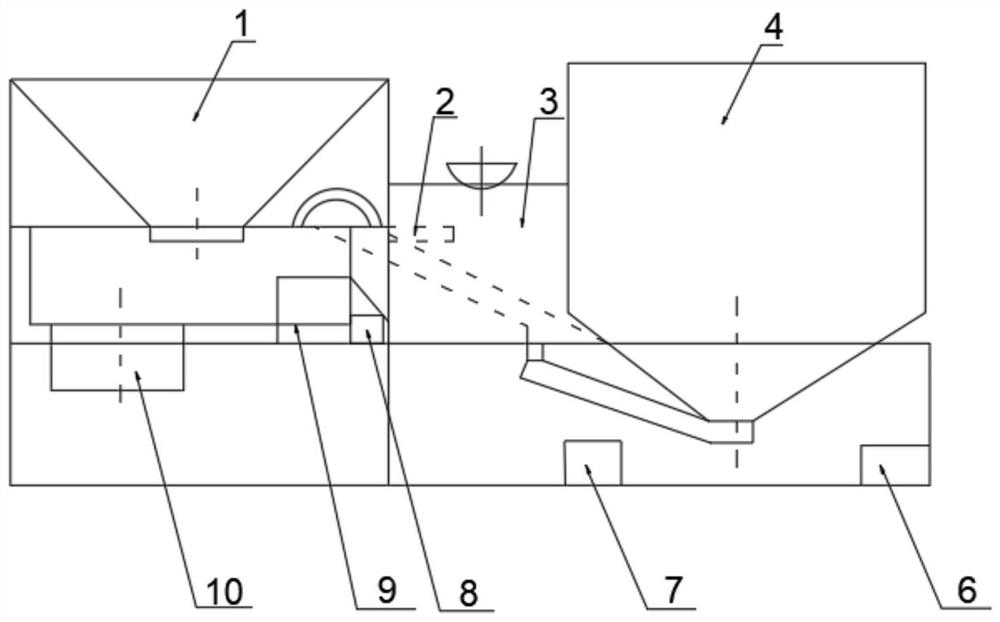

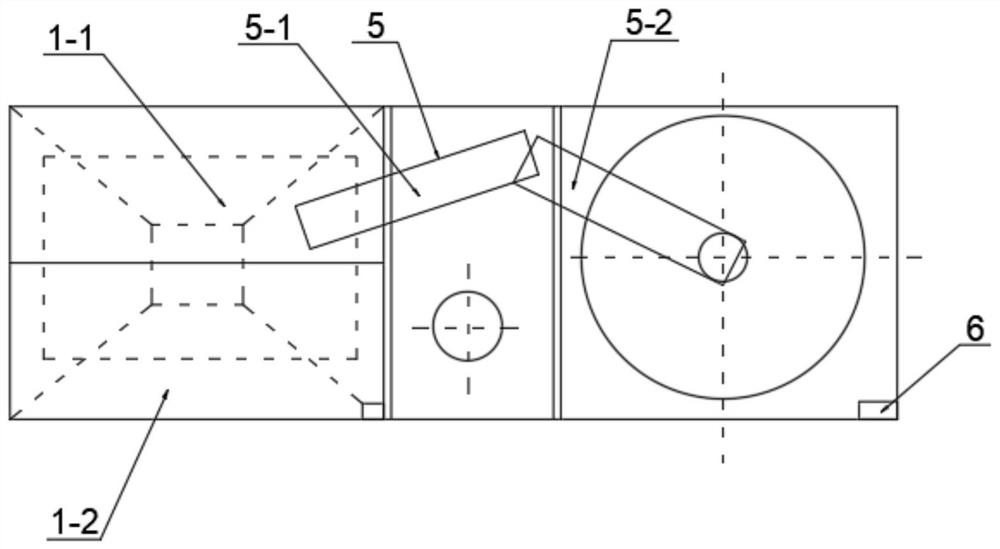

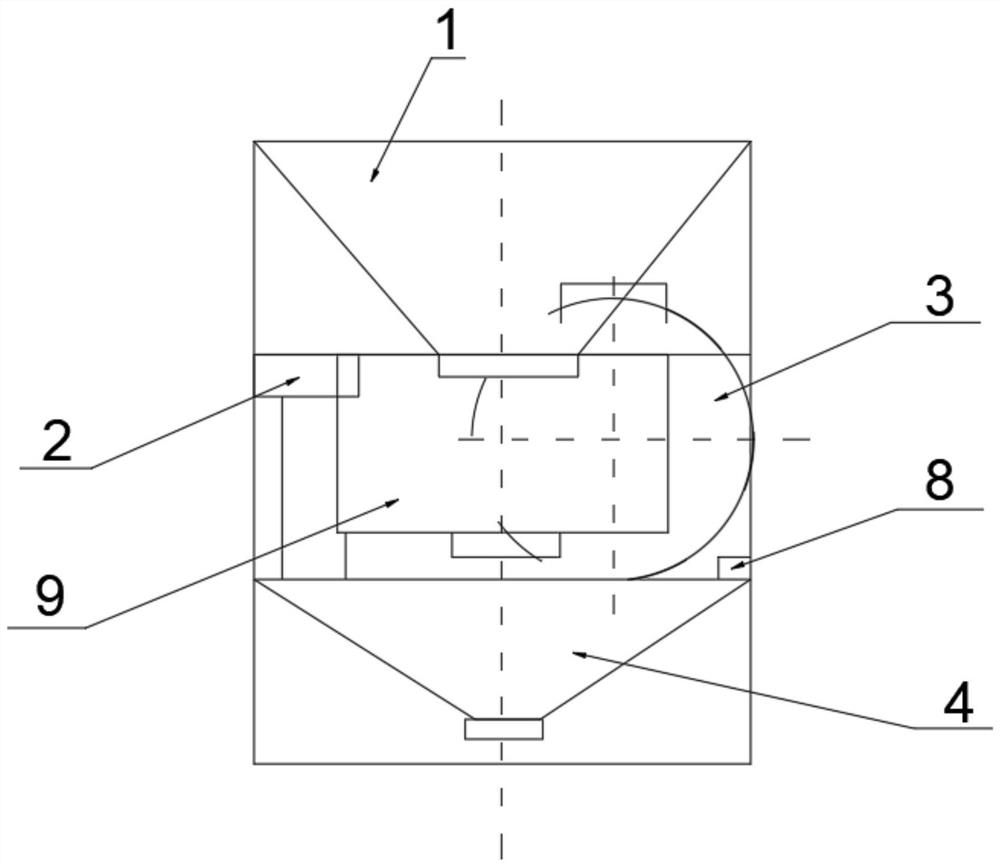

[0019] The present invention provides a concrete mortar intelligent production equipment during specific implementation, including feed bin 1, additive bin 2, water tank 3 and cement bin 4, described feed bin 1, additive bin 2, water tank 3 and cement bin 4 from the left Set up in turn from right to left, screw conveying equipment 5 is set between the silo 1 and the cement silo 4, a meter 8 and a mixer 9 are set at the bottom of the silo 1, and a mixer outlet is set at the bottom of the mixer 9. The feed port 10, the meter 8 is used for material metering, the water tank 3 is used in conjunction with the water pump, the additive storehouse 2 is provided with an additive port, and the inside of the water tank 3) is provided with a liquid level measuring device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com