A kind of environment-friendly asphalt high-viscosity additive and preparation method thereof

A high-viscosity, environmentally friendly technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of high-viscosity environmental pollution, high-viscosity difficult to melt and disperse, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of the environment-friendly asphalt high-viscosity additive according to any one of the above, comprising: mixing the styrene-butadiene-styrene block copolymer, the viscosity increasing component , the compatibilizing component, the high temperature viscosity modifier, the plasticizer, the anti-aging component and the accelerator are uniformly mixed and melted at a temperature of 150°C to 190°C, and then granulated to obtain The environment-friendly asphalt high-viscosity additive.

[0041] As a detailed description of the preparation method of the environment-friendly asphalt high-viscosity additive, a preparation method of the environment-friendly asphalt high-viscosity additive can be prepared as follows: block copolymerization of the styrene-butadiene-styrene compound, the tackifying component, the compatibilizing component, the high-temperature viscosity modifier, the plasticizer, the anti-aging component, an...

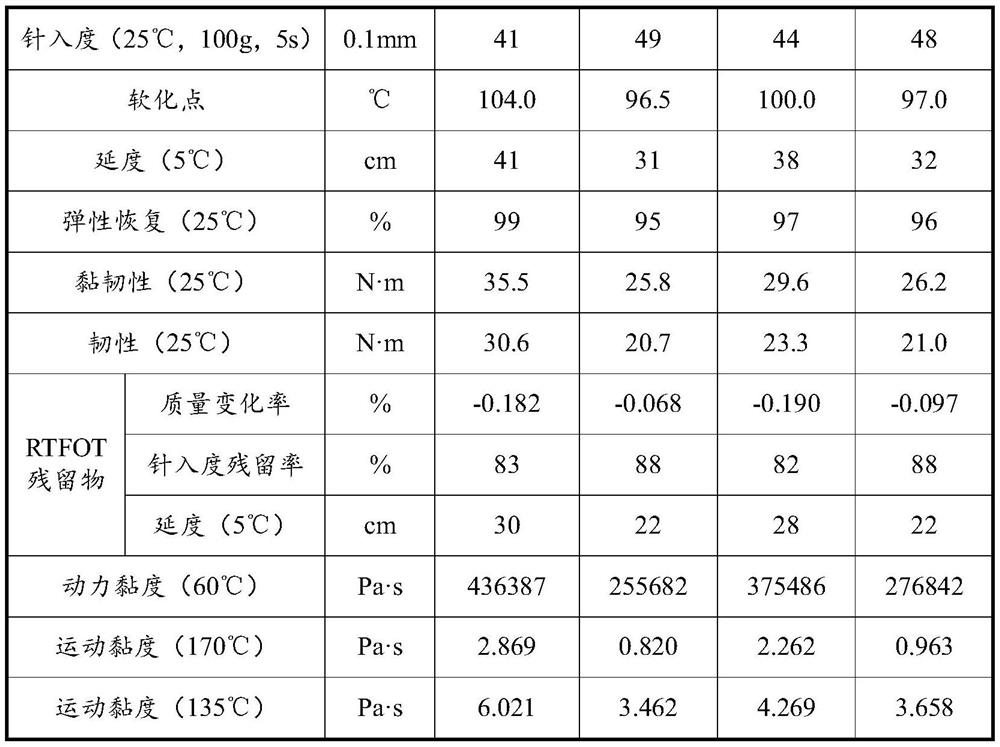

Embodiment 1

[0045] A high-viscosity additive, comprising in parts by mass: 100 parts of a styrene-butadiene-styrene block copolymer, 40 parts of a tackifying component, 10 parts of a compatibilizing component, 3 parts of a high-temperature viscosity regulator, 3 parts of plasticizer, 0.3 part of anti-aging component, 0.2 part of accelerator.

[0046] Among them, the styrene-butadiene-styrene block copolymer is linear SBS-YH791H (Sinopec Group Baling Petrochemical Branch); the tackifying component is carbon nine petroleum resin (Zibo Xinle Chemical Co., Ltd., softening The temperature is 120℃); the compatibilizing component is naphthenic rubber oil (China Petroleum Karamay Petrochemical Company); the high temperature viscosity modifier is 50% stearic acid amide (Zibo Xinrong Chemical Technology Co., Ltd.) and 50% polypropylene wax TS-5116 (Nanjing Tianshi New Material Technology Co., Ltd., melting point is 110°C); plasticizer is dioctyl phthalate (Jinan Huijinchuan Chemical Co., Ltd.); ant...

Embodiment 2

[0049] A high-viscosity additive, comprising in parts by mass: 100 parts of a styrene-butadiene-styrene block copolymer, 85 parts of a tackifying component, 30 parts of a compatibilizing component, 8 parts of a high-temperature viscosity regulator, 10 parts of plasticizer, 3 parts of anti-aging component, 1 part of accelerator.

[0050] Among them, the styrene-butadiene-styrene block copolymer is a star-shaped SBS road change 2#4303-2 (Sinopec Group Baling Petrochemical Branch); the tackifying component is C5 petroleum resin (Puyang Heng Tai Petrochemical Co., Ltd., the softening point is 130℃); the compatibilizing component is environmentally friendly aromatic oil (Zibo Guangyi Petrochemical Co., Ltd.); the high temperature viscosity modifier is 20% stearic acid amide (Zibo Xinrong Chemical Technology Co., Ltd. Company) and 80% polyethylene wax H100 (Qingdao Haihao Chemical Co., Ltd., the melting point is 100 ° C); the plasticizer is dioctyl terephthalate (Shandong Langtai Ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com