Environment-friendly plastic bottle

An environmentally friendly plastic and plasticizer technology, applied in the field of plastic product production, can solve the problems of difficult synthesis, difficult to popularize and apply, and high cost, and achieve the effects of reducing production costs, facilitating industrial production, and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

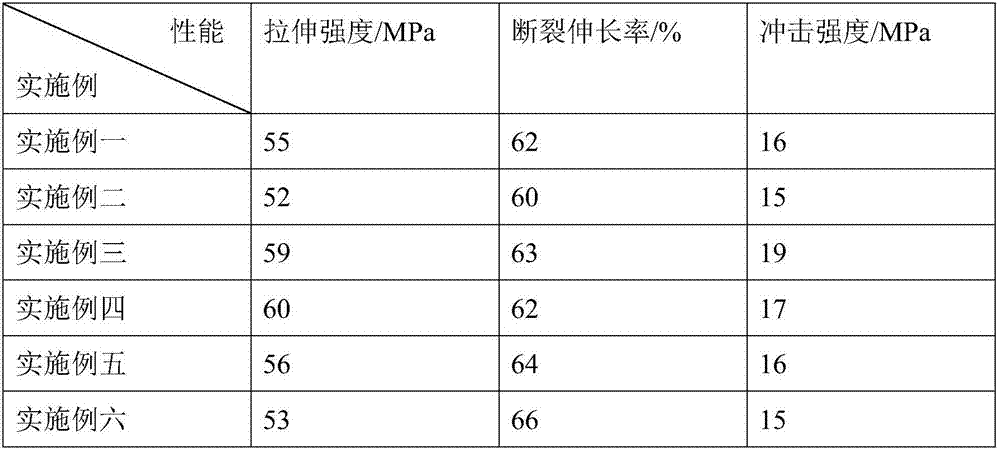

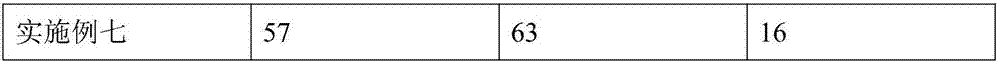

Examples

Embodiment 1

[0060] Polylactic acid / polypropylene blend A: 30 parts

[0061] Polylactic acid / starch / vegetable protein powder blend B: 30 parts

[0062] Polypropylene / starch / vegetable protein powder blend C: 110 parts

[0063] Antioxidant - Antioxidant 1010: 0.1 parts

[0064] Dispersant----liquid paraffin: 4.5 parts

[0065] Plasticizer: 6 parts, including 3 parts of glycerol, 3 parts of polylactic acid with a molecular weight of 5000-30000

[0066] Polylactic acid: 1 part

[0067] Polypropylene: 10 parts

[0068] Nucleating agent - calcium carbonate: 0.1 parts

[0069] Compatibilizer - phenyl o-hydroxybenzoate: 1 part

[0070] Chain extender - toluene diisocyanate: 1 to 5 parts,

[0071] After the above materials are dispersed by a high-speed mixer, they are melted and blended by a twin-screw extruder at 180-200°C, extruded into embryos, and finally blow-molded.

Embodiment 2

[0073] Polylactic acid / polypropylene blend C: 50 parts

[0074] Polylactic acid / starch / vegetable protein powder blend A: 20 parts

[0075] Polypropylene / starch / vegetable protein powder blend B: 20 parts

[0076] Antioxidant - Antioxidant DLTP: 0.5 parts

[0077] Dispersant----liquid paraffin: 0.5 parts

[0078] Plasticizer: 15 parts, including 10 parts of polyethylene glycol with a molecular weight of 400-2000, 5 parts of polylactic acid with a molecular weight of 5000-30000,

[0079] Polylactic acid: 10 parts

[0080] Polypropylene: 1 part

[0081] Nucleating agent - talcum powder: 0.5 parts

[0082] Compatibilizer----anhydride grafted polyethylene copolymer: 10 parts

[0083] Chain extender - diphenylmethane diisocyanate: 1 part,

[0084] After the above materials are dispersed by a high-speed mixer, they are melted and blended by a twin-screw extruder at 200-220°C, extruded into embryos, and finally blow-molded.

Embodiment 3

[0086] Polylactic acid / polypropylene blend B: 33 parts

[0087] Polylactic acid / starch / vegetable protein powder blend C: 25 parts

[0088] Polypropylene / starch / vegetable protein powder blend A: 15 parts

[0089] Antioxidant - Antioxidant 168: 0.3 parts

[0090] Dispersant ---- silicone oil: 3 parts

[0091] Plasticizer: 10 parts, including 4 parts of glycerol and 6 parts of ethylene glycol butyl ether acetate

[0092] Polylactic acid: 8 parts

[0093] Polypropylene: 5 parts

[0094] Nucleating agent - silicon dioxide: 0.3 parts

[0095] Compatibilizer - acrylamide grafted polyethylene: 5 parts

[0096] Chain extender - polymethylene polyphenyl polyisocyanate: 2 parts,

[0097] After the above materials are dispersed by a high-speed mixer, they are melted and blended by a twin-screw extruder at 190-210°C, extruded into embryos, and finally blow-molded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com