Hard asphalt mixture and preparation method thereof

A hard asphalt and mixture technology, applied in the field of modified asphalt, can solve problems such as poor low temperature performance, reduced performance of asphalt mixture, and thermal aging of asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

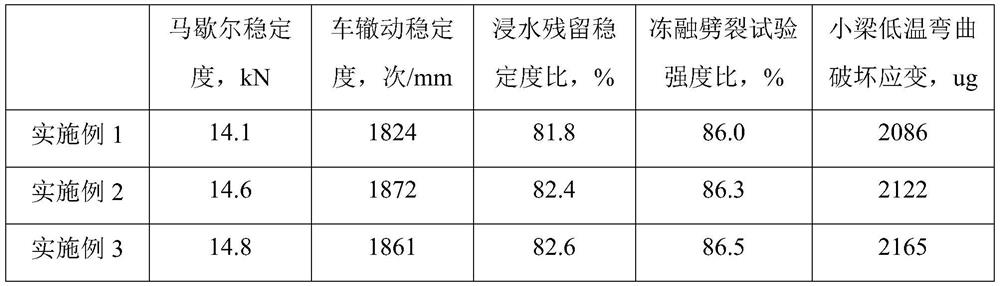

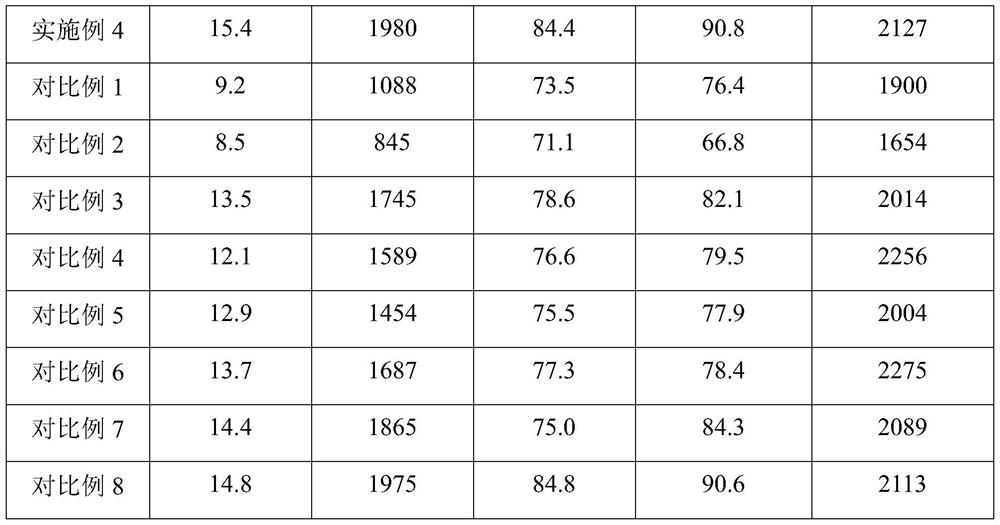

[0019] A kind of hard asphalt mixture, made of the following components by weight: 4.2 parts of modified hard asphalt, 92 parts of aggregate, 1.0 part of mineral powder, wherein, the modified hard asphalt is made of modified Agent and matrix asphalt are made by weight ratio 3:7, and described modifying agent adopts the following steps to prepare: a, the nano hydrotalcite powder of 1 weight part (purchased in Dalian Fumeida New Material Technology Co., Ltd., the same below) is added In 5 parts by weight of ethylene glycol, after ultrasonic dispersion, the pH value is adjusted to 4.0 to obtain a slurry; 2 parts by weight of benzoic acid are dissolved in 5 parts by weight of ethylene glycol, and the slurry is added dropwise to the resulting solution , stirred and reacted at 130°C for 2 hours, suction filtered, and the supernatant was taken and washed with water until neutral, and dried to obtain modified nano hydrotalcite powder; b. (purchased from Jiangyin Dongpeng International...

Embodiment 2

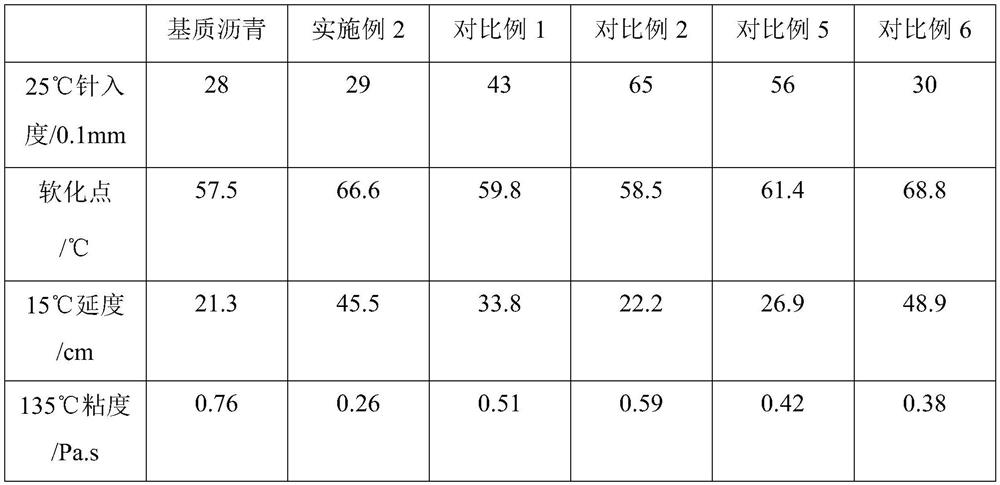

[0023] A kind of hard asphalt mixture, made of the following components by weight: 4.5 parts of modified hard asphalt, 93 parts of aggregate, 1.1 parts of mineral powder, wherein, the modified hard asphalt is made of modified Agent and matrix asphalt are made by weight ratio 3:7, and described modifying agent adopts the following steps to prepare: a, the nano hydrotalcite powder of 1 weight part is added in the ethylene glycol of 5 weight parts, after ultrasonic dispersion, adjust pH value to 4.0 to prepare a slurry; 2 parts by weight of benzoic acid were dissolved in 5 parts by weight of ethylene glycol, and the slurry was added dropwise to the resulting solution, stirred and reacted for 2 hours at 130°C, suction filtered, and and washing with water to neutrality, and drying to obtain modified nano hydrotalcite powder; b, placing the modified nano hydrotalcite powder, linear bisphenol A phenolic resin and oxidized polyethylene wax in a weight ratio of 2:7:3 Fully mixed in a h...

Embodiment 3

[0026]A kind of hard asphalt mixture, made of the following components by weight: 4.8 parts of modified hard asphalt, 94 parts of aggregate, 1.2 parts of mineral powder, wherein, the modified hard asphalt is made of modified Agent and matrix asphalt are made by weight ratio 3:7, and described modifying agent adopts the following steps to prepare: a, the nano hydrotalcite powder of 1 weight part is added in the ethylene glycol of 5 weight parts, after ultrasonic dispersion, adjust pH value to 4.0 to prepare a slurry; 2 parts by weight of benzoic acid were dissolved in 5 parts by weight of ethylene glycol, and the slurry was added dropwise to the resulting solution, stirred and reacted for 2 hours at 130°C, suction filtered, and and washing with water to neutrality, and drying to obtain modified nano hydrotalcite powder; b, placing the modified nano hydrotalcite powder, linear bisphenol A phenolic resin and oxidized polyethylene wax in a weight ratio of 2:7:3 Fully mixed in a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com