PCB character ink-jet nano color paste as well as preparation method and application thereof

A nano-color paste and character technology, applied in applications, inks, household appliances, etc., can solve the problems of easy falling off and poor stability of PCB board ink, and achieve the effects of not easy falling off, excellent anti-settling performance and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The second aspect of the embodiment of the present application provides a method for preparing a PCB character inkjet nano-color paste, including the following steps:

[0048] S01. Provide various components according to the PCB character inkjet nano-color paste;

[0049] S02. Performing the first mixing treatment on the acrylate monomer, dispersant and auxiliary agent to obtain the first mixture;

[0050] S03. performing a second mixing treatment on the first mixture, titanium dioxide, and aluminum hydroxide to obtain a second mixture;

[0051] S04. The second mixture is sequentially subjected to grinding treatment and filtration treatment to obtain PCB character inkjet nano color paste.

[0052] The preparation method of the PCB character inkjet nano-color paste provided by the second aspect of the present application, the preparation method is through mixing each component, and then performing grinding treatment and filtering treatment, so as to ensure that the PCB ...

Embodiment 1

[0066] PCB character ink-jet nano color paste and its preparation method and PCB ink-jet ink

[0067] PCB character inkjet nano color paste

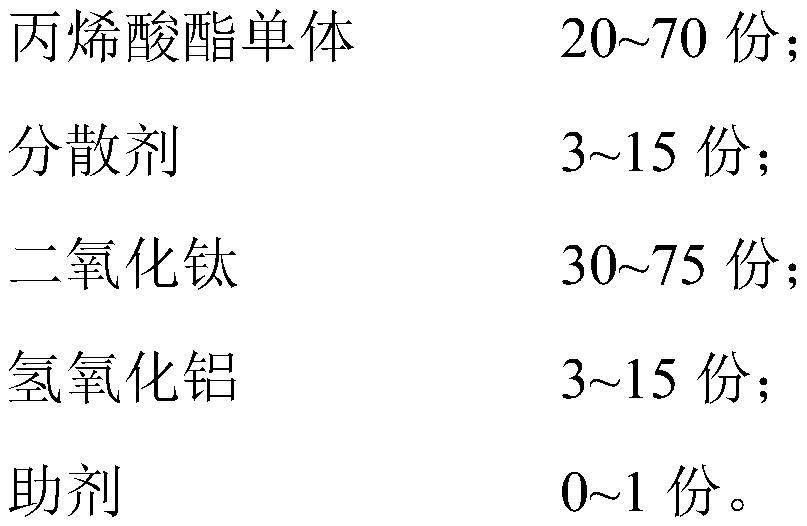

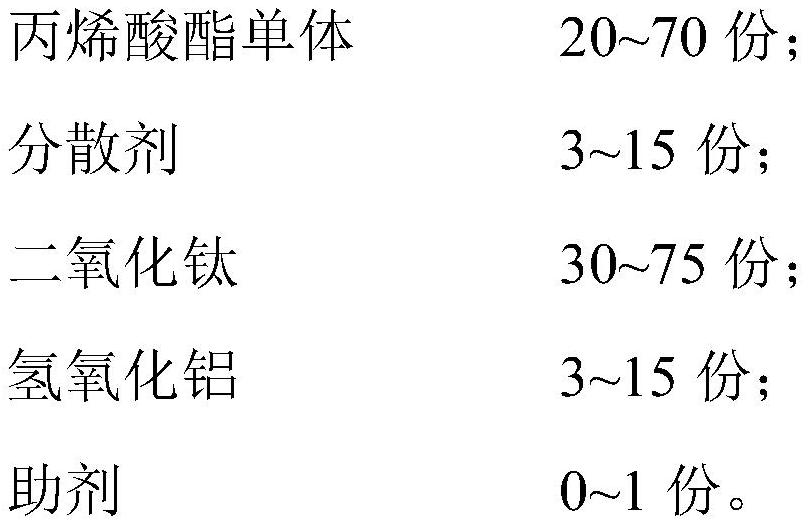

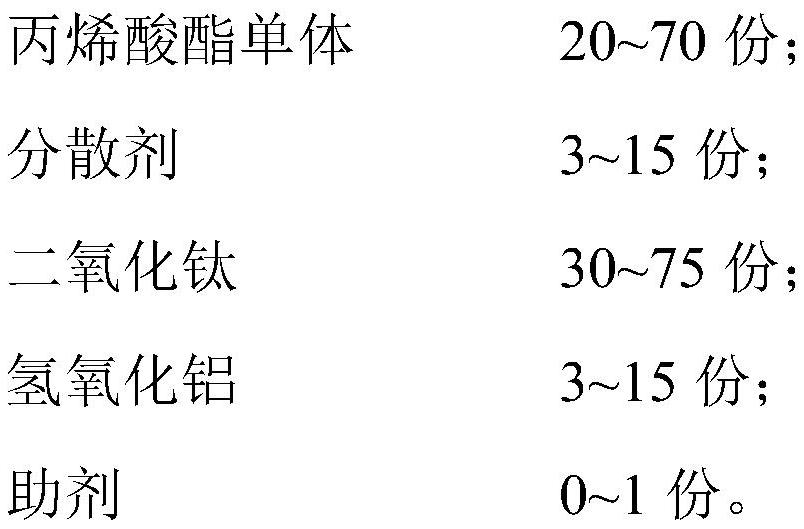

[0068] The PCB character inkjet nano color paste includes the following components in parts by weight:

[0069]

[0070] Preparation method of PCB character inkjet nano color paste

[0071] Provide various components according to PCB character inkjet nano color paste;

[0072] Perform the first mixing treatment on the acrylate monomer, dispersant and auxiliary agent under the condition of 200-400 rpm for 0.5-1 hour to obtain the first mixture;

[0073] performing a second mixing treatment on the first mixture, titanium dioxide, and aluminum hydroxide at 300-600 rpm for 2 hours to obtain a second mixture;

[0074] Grinding and filtering the second mixture in turn to obtain PCB character inkjet nano-color paste; grinding treatment is to provide ceramic nano-sand mill and zirconium beads for grinding, wherein the filling amount of ...

Embodiment 2

[0078] PCB character ink-jet nano color paste and its preparation method and PCB ink-jet ink

[0079] PCB character inkjet nano color paste

[0080] Among the titanium dioxide components included in the PCB character inkjet nano-color paste, there are 20 parts of Lomon Billions TR52 and 30 parts of Sahaliben RM300. The other components and preparation method of PCB character inkjet nano-color paste are consistent with those in Example 1.

[0081] PCB inkjet ink

[0082] The PCB inkjet ink includes the PCB character inkjet nano-color paste provided in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com