Efficient decarburization method for RH refining furnace

A refining furnace and high-efficiency technology, applied in the field of iron and steel metallurgy, can solve problems such as the inability to smelt ultra-low carbon steel quickly, and achieve the effects of shortening the vacuum treatment time, increasing the generation of inclusions, and avoiding secondary oxidation on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

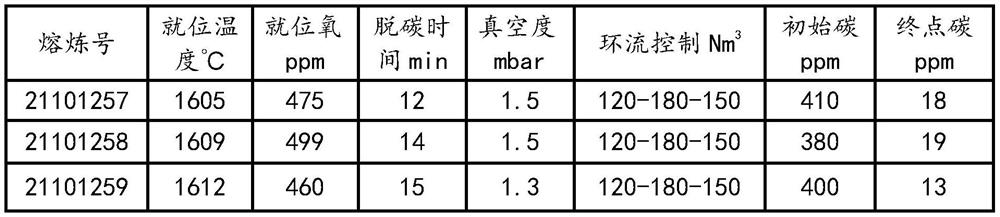

[0032] Ultra-low carbon steel is smelted from molten steel with a carbon content of 0.041%. The in-place temperature of the RH furnace is 1605°C, and the oxygen is 475ppm. Apply the "three-stage" circulation control method, specifically the pressure drop period of 120Nm 3 / h, decarburization period 180Nm 3 / h, pure degassing period 150Nm 3 / h, the minimum vacuum degree is 1.5mbar, the decarburization period is 12min, and the carbon end point is 18ppm.

Embodiment 2

[0034] Ultra-low carbon steel is smelted with molten steel with a carbon content of 0.038% as raw material. The in-place temperature of the RH furnace is 1609°C, and the oxygen is 499ppm. Apply the "three-stage" circulation control method, specifically the pressure drop period of 120Nm 3 / h, decarburization period 180Nm 3 / h, pure degassing period 150Nm 3 / h, the minimum vacuum degree is 1.5mbar, the decarburization period is 14min, and the end carbon is 19ppm.

Embodiment 3

[0036] Ultra-low carbon steel is smelted with molten steel with a carbon content of 0.040% as raw material. The in-place temperature of the RH furnace is 1612°C, and the oxygen is 460ppm. Apply the "three-stage" circulation control method, specifically the pressure drop period of 120Nm 3 / h, decarburization period 180Nm 3 / h, pure degassing period 150Nm 3 / h, the minimum vacuum degree is 1.5mbar, the decarburization period is 14min, and the end carbon is 19ppm.

[0037] Table 1 below shows the relevant decarbonization effect data for the three cases.

[0038] Table 1

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com