Asbestos standard test piece preparation device for polarizing microscope and test piece preparation method

A technology of polarizing microscope and preparation device, which is applied in the preparation of test samples, measuring device, sampling, etc., to achieve the effect of simplifying test operation steps, stable and controllable results, and saving test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

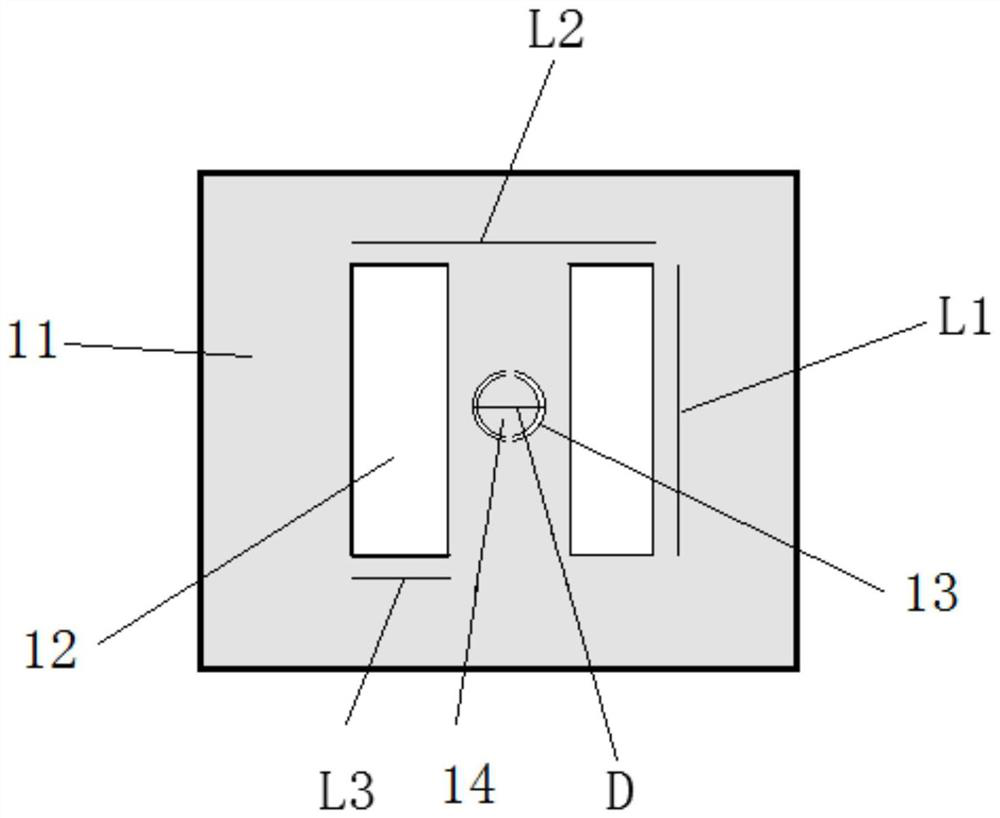

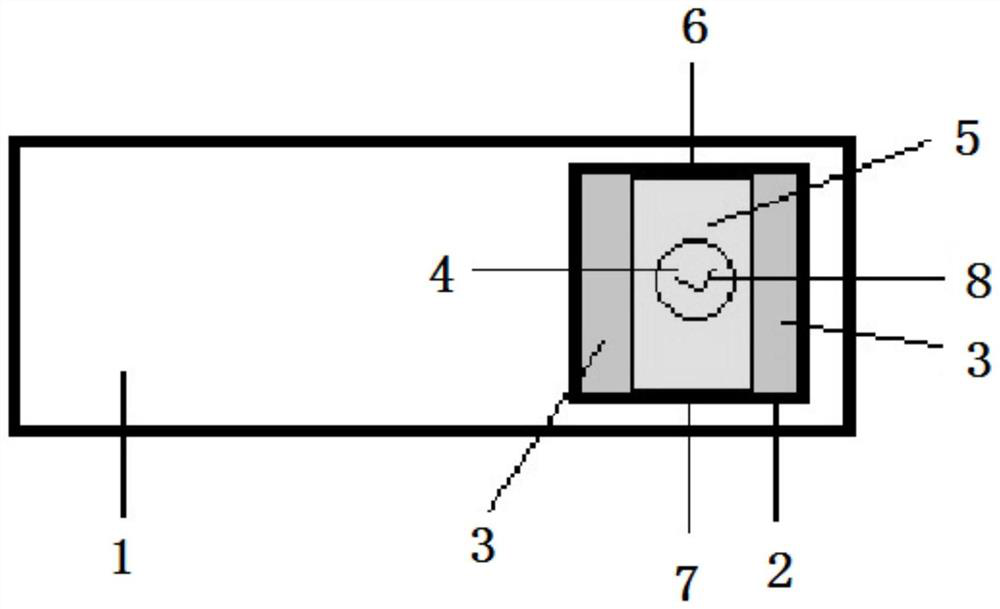

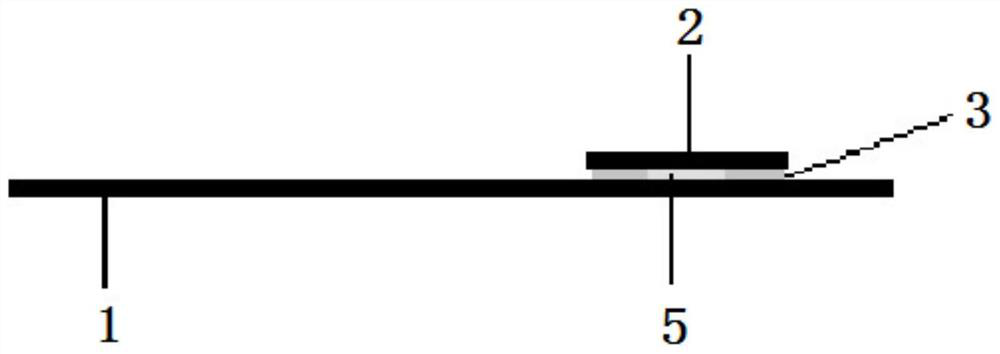

Method used

Image

Examples

Embodiment 1

[0069] Preparation and use of a serpentine asbestos (chrysotile) standard test piece for a polarizing microscope:

[0070] Take one of the slides, clean the surface with water and dry it. Select a suitable area and cover the corrosion device; use a clean brush to pick up an appropriate amount of hydrofluoric acid, and apply it to the hollowed out position of the corrosion device. After 5 minutes, it was observed that there was corrosion on the glass surface, and the corrosion device was removed, and the surface of the glass slide was cleaned immediately with clear water. The surface of the slide glass is corroded, and the fixation area, the dipping area and the slide area can be distinguished. Transfer 200 microliters of the asbestos standard substance solution to the slide area, and let it dry naturally.

[0071] Add a certain amount of neutral gum dropwise on the fixed area, the amount is enough to cover the fixed area, cover with the cover glass and compact it. Then natu...

Embodiment 2

[0074] A method of making and using a standard test piece of amphibole asbestos (anthophyllite, tremolite, actinolite, crocidolite, amosite, etc.) for a polarizing microscope:

[0075] Take a glass slide, clean the surface with water and let it dry. Select a suitable area and cover the corrosion device; use a clean brush to pick up an appropriate amount of hydrofluoric acid, and apply it to the surface of the corrosion device and the hollowed out position. After 10 minutes, the corrosion device was removed, and the surface of the glass slide was immediately cleaned with water. The surface of the slide glass is corroded to form the fixed area, the dipping area and the observation area. Transfer 500 microliters of the asbestos standard substance solution to the slide area, and let it dry under light. A certain amount of neutral gum is dropped on the fixed area 3, covered with the cover glass, and compacted. Then accelerate curing under light, and then make standard test piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com