Multi-working-mode ion chromatograph

An ion chromatograph and working method technology, applied in the direction of instruments, scientific instruments, material separation, etc., can solve the problems of unstable working flow rate of plunger pumps, unstable detection baseline fluctuations, leakage at multi-pipeline connections, etc., to avoid problems such as The effect of lack of liquid, improving the problem of lack of liquid, and stable working flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

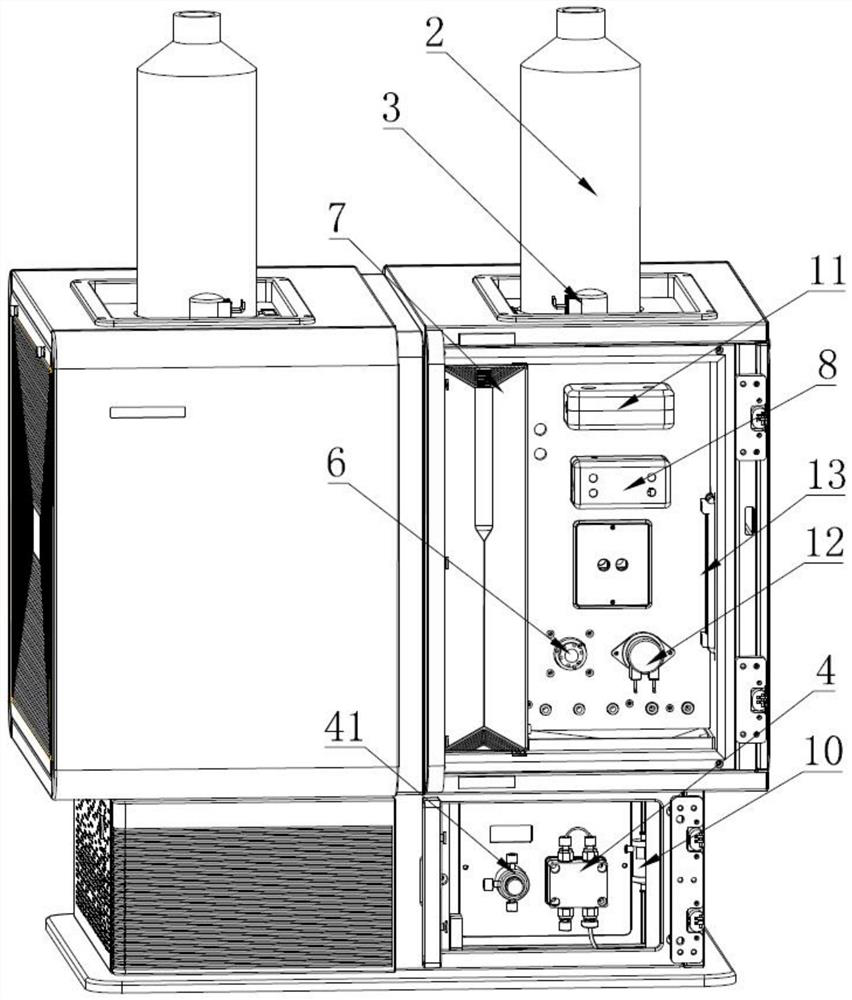

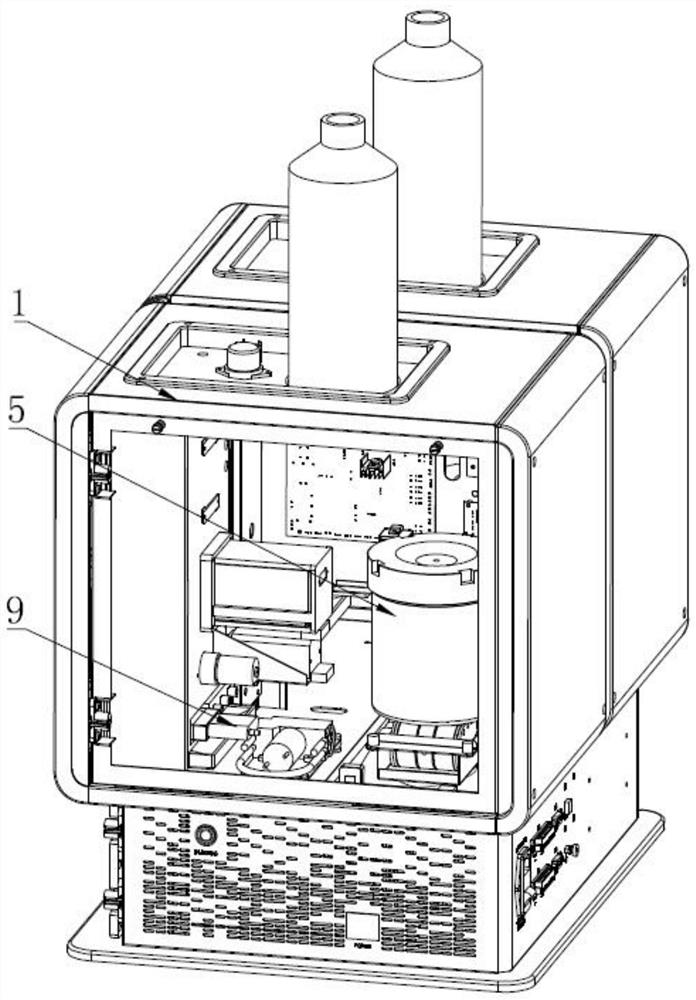

[0032] Such as Figure 1 to Figure 9 As shown, an ion chromatograph with multiple working modes includes a detection case 1, a pure water bottle 2, a first peristaltic pump 3, a gas-liquid separator 10, a plunger pump 4, an eluent generator 5, and a sampling valve 6 , a chromatographic column 7, a suppressor 8 and a conductivity detector, the pure water bottle 2 is arranged on the detection cabinet 1, one end of the first peristaltic pump 3 is connected to the pure water bottle 2, and the other end is connected to the inlet of the gas-liquid separator 10 , the outlet of the gas-liquid separator 10 is connected to the head end of the plunger pump 4, the side wall of the gas-liquid separator 10 is provided with an overflow port 101, the plunger pump 4 is connected to a pressure sensor 41, the The end of the plunger pump 4 is connected to the inlet of the eluent generator 5, the outlet of the eluent generator 5 is connected to the inlet of the injection valve 6, the outlet of the...

Embodiment 2

[0040] On the basis of the technical solution of the above embodiment, a second peristaltic pump 12 is also included, one end of the sampling valve 6 is connected to the sample bottle, and the other end is connected to the inlet of the second peristaltic pump 12, and the outlet of the second peristaltic pump 12 is connected to waste liquid bottle. By setting the second peristaltic pump 12 inside the detection cabinet 1, the second peristaltic pump 12 provides sufficient pump suction for the sampling valve 6, and the sample to be tested is sucked from the sample bottle to the quantitative loop of the sampling valve 6, which can realize The automatic sampling of test samples and the quantitative intake of samples can be realized according to the actual test requirements, and the use process is more convenient; if the excess samples are sucked and passed through the second peristaltic pump, they are directly discharged into the waste liquid bottle, which can effectively ensure the...

Embodiment 3

[0042] The difference from the technical solution of Embodiment 2 is that one end of the second peristaltic pump 12 is connected to the outlet of the pure water bottle 2 or the ultrapure ion purifier 11 , and the other end is connected to the post flushing channel of the plunger pump 4 . By installing a second peristaltic pump 12 inside the detection cabinet 1, the two ends of the second peristaltic pump 12 are respectively connected to the outlet of the pure water bottle 2 or the ultrapure ion purifier 11 and the post-rinsing channel of the plunger pump 4, so that column alignment can be achieved. The post-flushing operation of the plunger pump 4 avoids crystallization inside the plunger pump 4, prevents the wear of the plunger rod and the sealing ring, and prolongs the service life of the plunger pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com