A voltage-controlled emitter turn-off thyristor device and its manufacturing method

A thyristor and emitter technology, which is used in semiconductor/solid-state device manufacturing, thyristor, semiconductor devices, etc., can solve the problems of complex control when the device is turned on and off, difficult to meet the requirements of converter control technology, and slow dynamic response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment, describe technical solution of the present invention in detail:

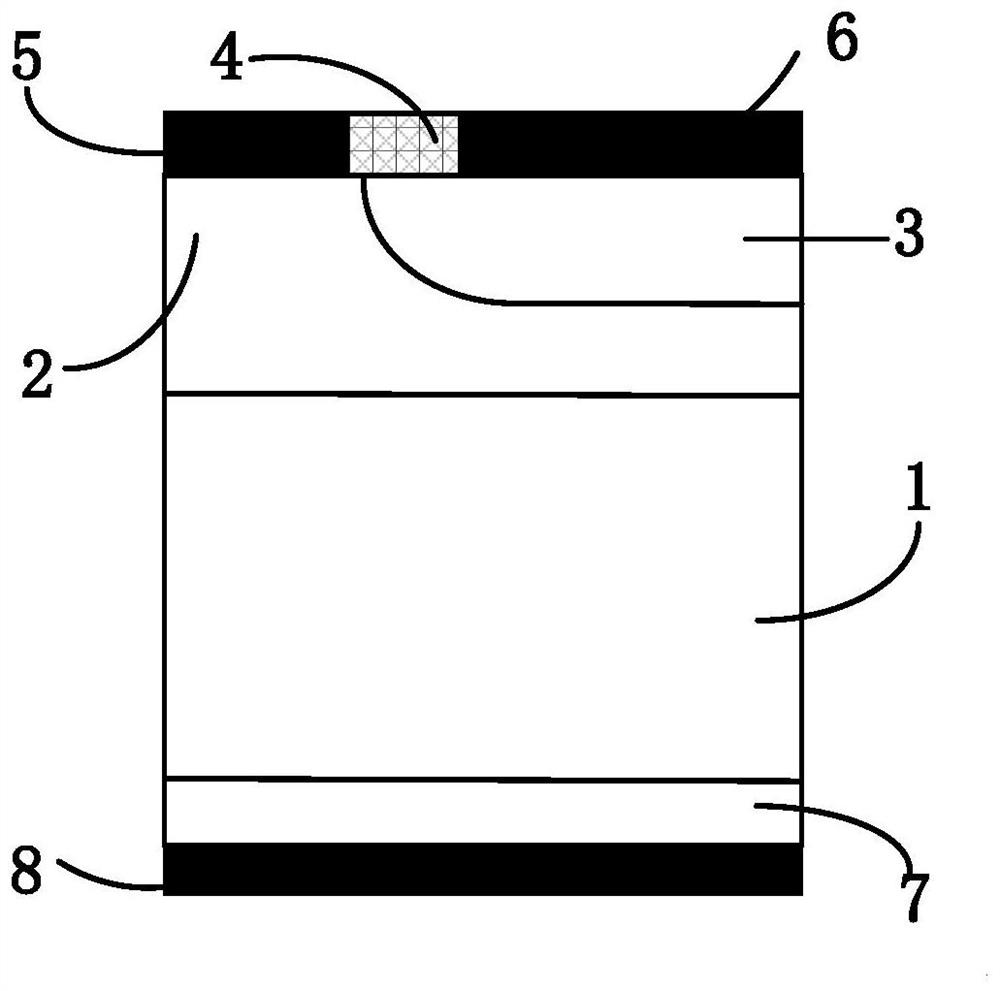

[0040] figure 1 It is a schematic diagram of the structure of a conventional GTO device.

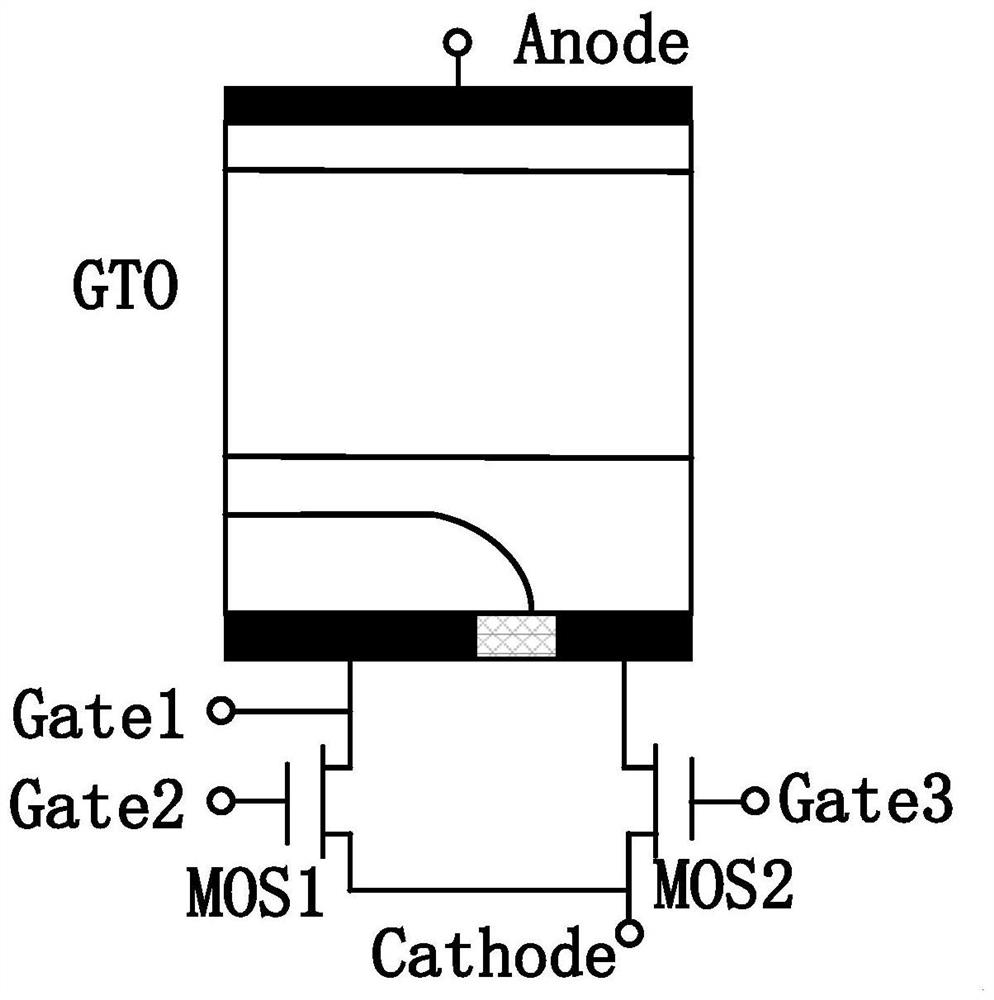

[0041] figure 2 It is a schematic structural diagram of an ETO device composed of a conventional GTO and two MOSs. It has a parasitic thyristor structure, which has a large di / dt when it is turned on, and a small conduction voltage drop when it is turned on. However, since the emitter turn-off thyristor (ETO) has three gates, the control when the device is turned on and off is complicated. Although the ETO device only needs to control the gate voltage when it is turned off, it needs to inject a strong current trigger pulse into the GTO gate when the ETO is turned on, so its driving circuit is complicated and it is not conducive to improving the reliability of the system.

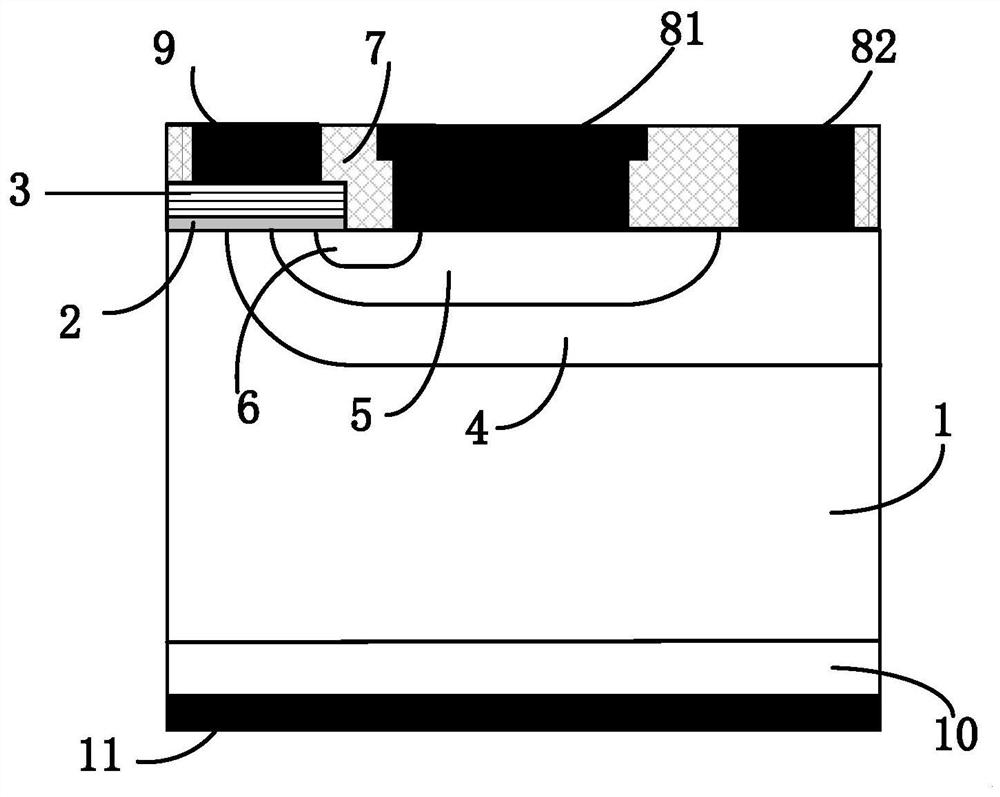

[0042] image 3 It is a structural schematic diagram of a MOS gate-controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com