Polycrystalline silicon resistor, manufacturing method thereof and successive approximation analog-to-digital converter

A technology of polysilicon resistors and manufacturing methods, applied in analog/digital conversion, resistors, code conversion, etc., can solve problems such as the non-linearity of polysilicon resistance layers, improve linearity, reduce integral non-linearity, and eliminate current-carrying The effect of sub-edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

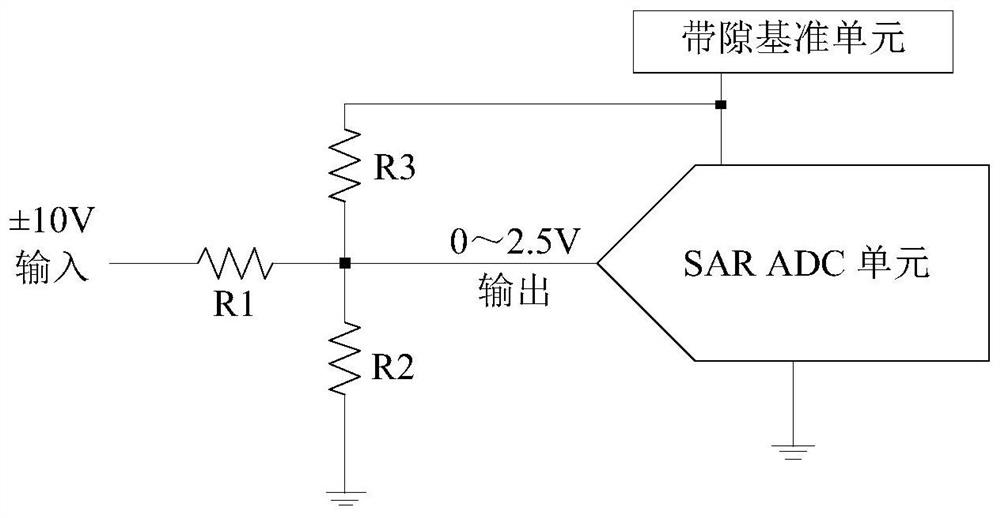

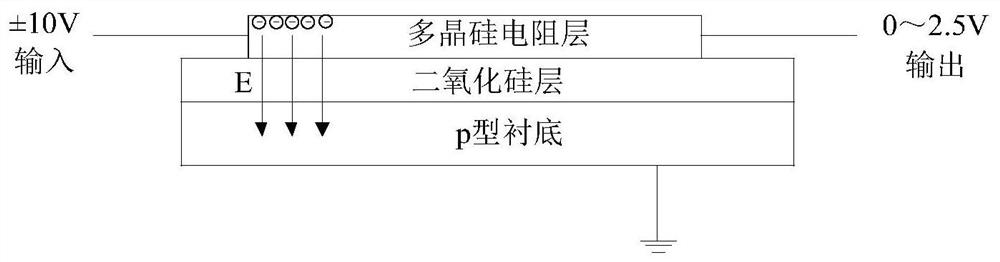

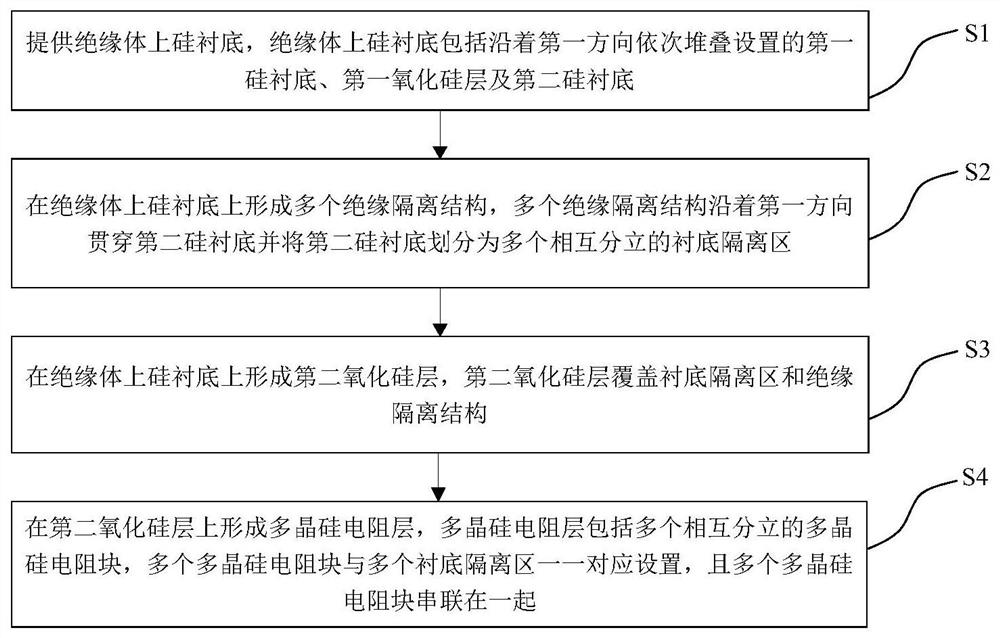

[0042] The inventors have found that: Figure 1-Figure 2 As shown, in the current industrial successive approximation analog-to-digital converter, when the traditional polysilicon resistor is used as the voltage divider network design, a strong electric field E will be formed at the high voltage end, while the electric field at the low voltage end is weak, and the high voltage of the polysilicon resistor Carriers at the low-voltage side of the polysilicon resistor have edge-to-edge effect and the resistivity increases, while the carrier-to-edge effect on the low-voltage end of the polysilicon resistor is not obvious and the resistivity hardly increases, which makes the resistivity of the polysilicon resistor inconsistent between the high-voltage end and the low-voltage end, causing very serious problems. Non-linearity, and the nonlinearity of the resistor divider network will cause the nonlinearity of the successive approximation analog-to-digital converter; experiments have pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com