Peanut husking machine based on laser pretreatment

A technology of laser pretreatment and shelling machine, which is applied in the direction of shelling, solid separation, filtering, etc., which can solve the problems of high damage rate of peanut seeds, troublesome replacement process, and finger fatigue, so as to improve the efficiency of shelling and the scope of application Wider, reduce the effect of damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Embodiment 1, when the existing peeling machine carries out shelling process to peanut pods, when peanut pods are rubbed, hit or crushed, it will cause great damage to peanut seeds, resulting in a higher breakage rate of peanut seeds, making Peanut seed coats and germs are damaged to varying degrees, and after the peanut seed coats and germs are damaged, they cannot meet the requirements for making seeds, and when the existing shelling machines shell different types of peanut pods, due to different Peanut pods of different varieties have different sizes, so it is necessary to replace the concave screen of the sheller to shell different varieties of peanut pods. The replacement process is troublesome and time-consuming, which reduces the shelling efficiency of peanut pods. The use has certain limitations and is inconvenient to use.

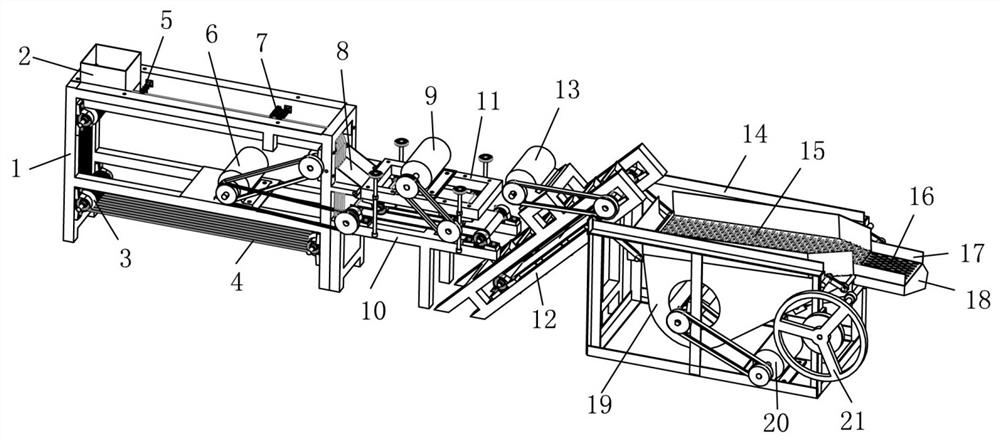

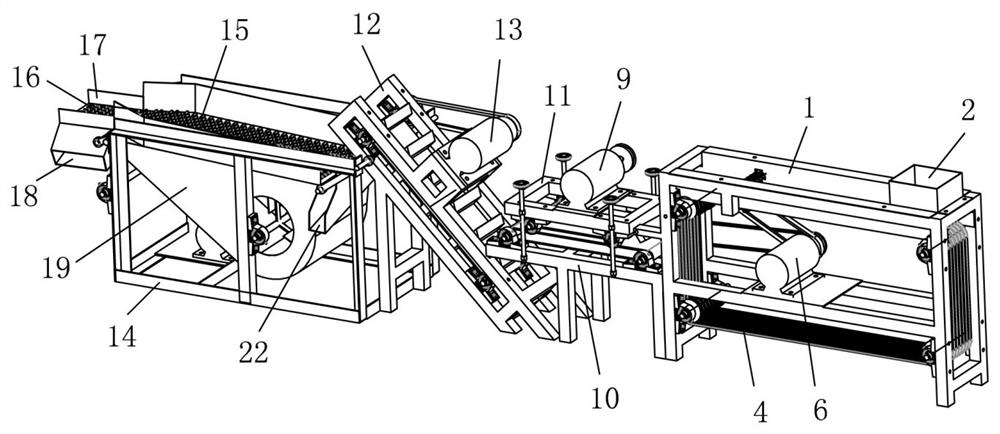

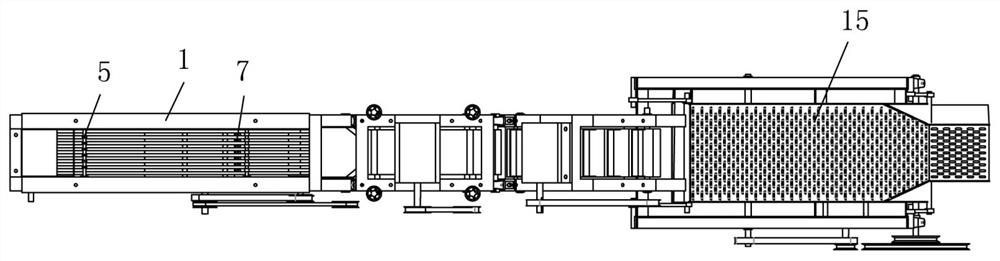

[0034] In view of the above problems, the present embodiment provides a peanut sheller based on laser pretreatment, such as Figure 1-2 As ...

Embodiment 2

[0038] Embodiment 2, a peanut sheller based on laser pretreatment in this implementation will be described centering on the differences from Embodiment 1.

[0039] In this embodiment, the surfaces of the lower kneading belt 24 and the upper kneading belt 26 are evenly distributed with tiny bosses. When the peanut pods are kneaded and peeled by the lower kneading belt 24 and the upper kneading belt 26, the peanut pods can be better treated. Knead to improve the rubbing efficiency of peanut pods.

Embodiment 3

[0040] Embodiment 3, a peanut sheller based on laser pretreatment in this implementation will be described centering on the differences from Embodiment 1.

[0041] In this embodiment, the fish scale vibrating screen 15 is installed in the cleaning frame 14 with an inclination of 20° upward to the horizontal plane. The end is hinged with the cleaning frame 14 through the second hinged rod 34, and through the inclined setting of the scale vibrating screen 15, the blower fan 35 can better remove the peeled peanut pods from the scale vibrating screen 15 or the peanut pods that have not been peeled clean. Pod discharge port 22 winnows and discharges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com