Separation device for solvent in ultrahigh-molecular-weight polyethylene fiber pre-drawing hot water

A polyethylene fiber and ultra-high molecular weight technology, which is applied in the field of ultra-high molecular weight polyethylene fiber pre-drawing hot water solvent separation device, can solve the problems of time-consuming and laborious separation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

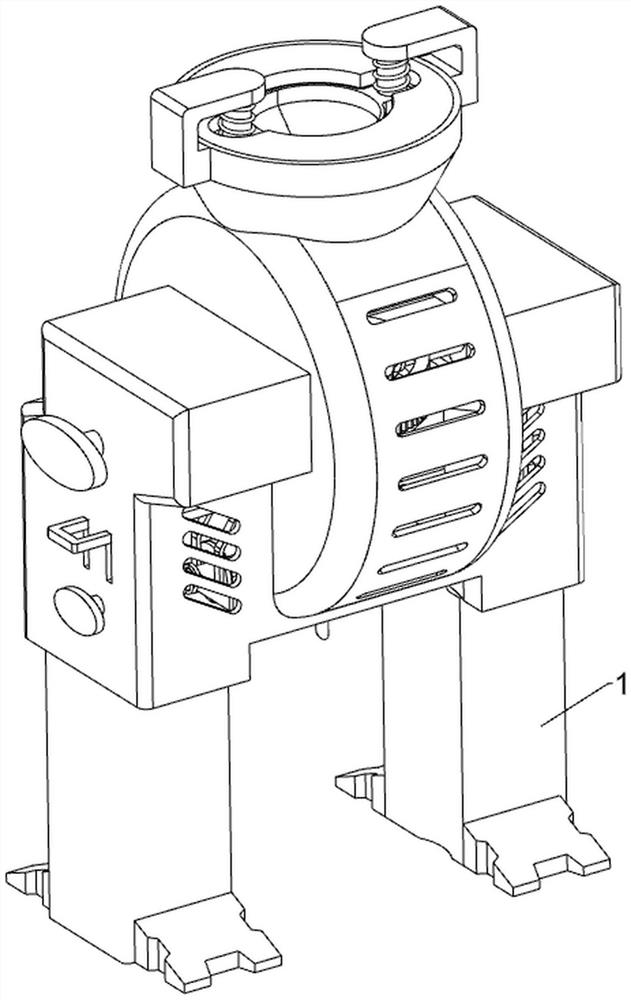

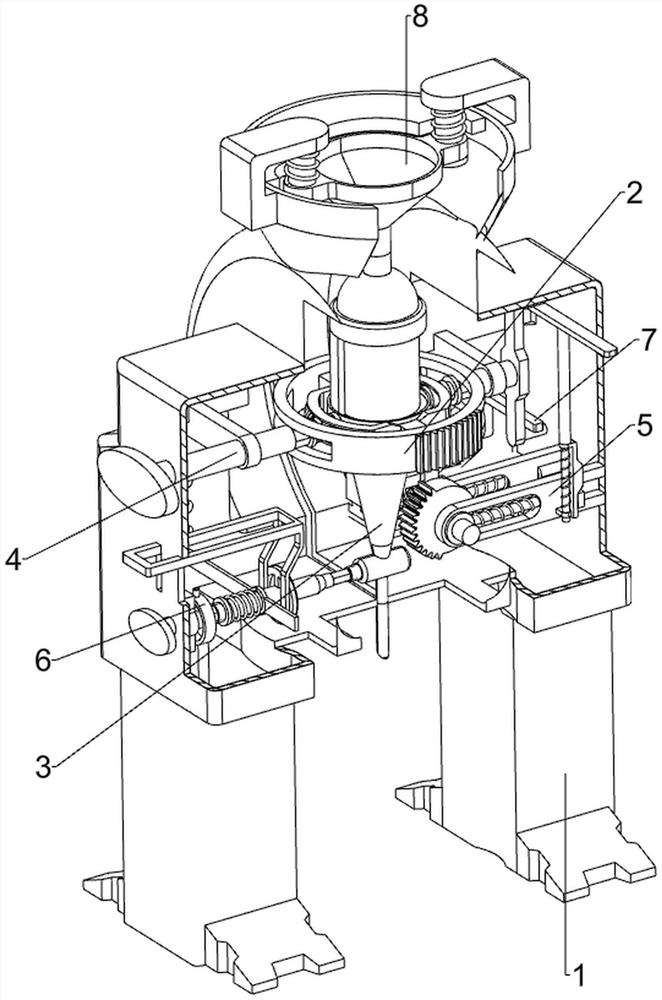

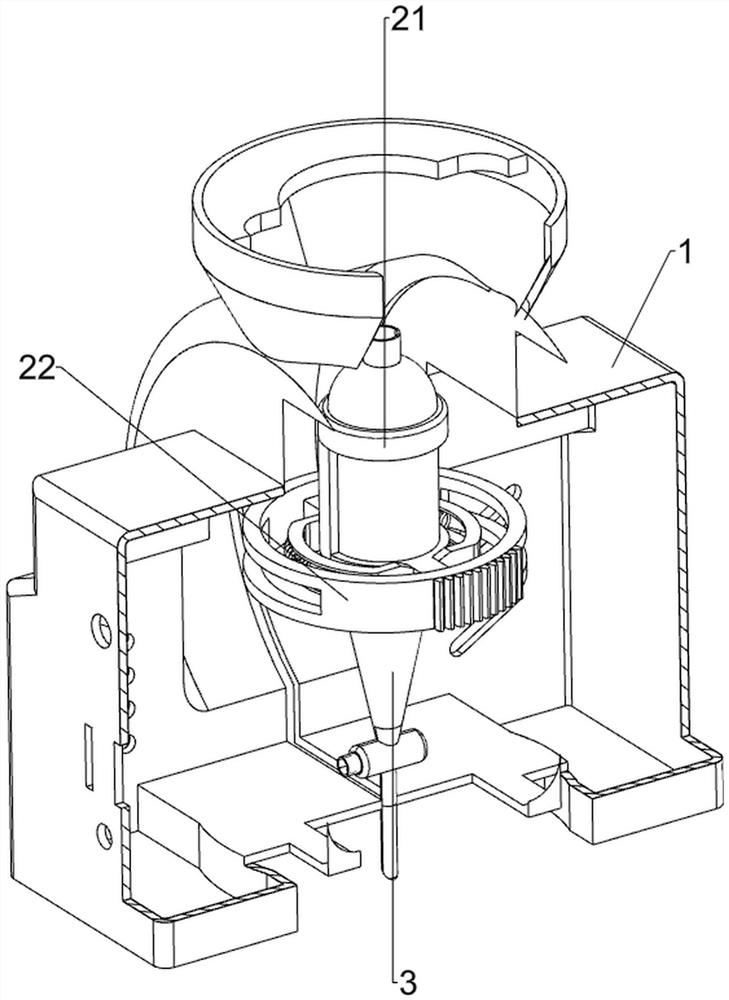

[0036] like figure 1 and figure 2 As shown, an ultra-high molecular weight polyethylene fiber pre-drawing hot water solvent separation device includes a housing 1, a placement mechanism 2, a liquid filling tank 3, a rotating mechanism 4 and a shaking mechanism 5, and the middle position inside the housing 1 is slidingly provided with The liquid filling tank 3 is provided with a placement mechanism 2, the inner wall of the rear side of the casing 1 is provided with a rotating mechanism 4, and the inner wall of the lower right side of the casing 1 is provided with a shaking mechanism 5, and the shaking mechanism 5 and the placement mechanism 2 Cooperate.

[0037] When the solvent needs to be separated, the staff pours the solvent to be separated into the liquid filling tank 3. After completion, the staff closes the bottom of the liquid filling tank 3 by rotating the placement mechanism 2. At this time, the staff rotates the rotating mechanism 4 Make the liquid filling tank 3 ...

Embodiment 2

[0039] like figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 As shown, on the basis of Embodiment 1, the placement mechanism 2 includes a first fixed block 21, a first chute plate 22, a rack 23, a first spring 24 and a regulating valve 25, and the outer wall of the liquid filling tank 3 is arranged There is a first fixed block 21, the first fixed block 21 is provided with a first chute plate 22, the front side of the first chute plate 22 is provided with a rack 23, and the left and right sides of the first fixed block 21 are connected with first springs 24, the lower part of the liquid tank 3 is rotatably provided with a regulating valve 25 .

[0040] The rotating mechanism 4 includes a first twisting block 41, a second fixed block 42, a rotating rod 43, a hexagonal sleeve 44 and a connecting ring 45. The right end of the block 41 cooperates with the first spring 24 on the left side. Two second fixed blocks 42 are arranged on ...

Embodiment 3

[0044] like figure 2 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, on the basis of Embodiment 2, an opening and closing assembly 6 is also included. The opening and closing assembly 6 includes a second twist block 61, a rotating shaft 62, a stopper 63, a fourth spring 64, a limit rod 65, Limiting groove plate 66 and guide plate 67, the outer wall of shell 1 bottom left side is provided with the second twisting block 61 in rotation, the left side of shell 1 bottom is movably provided with rotating shaft 62, and rotating shaft 62 left ends and second twisting block The inner end of 61 is slidably connected by a coupling, the right end of the rotating shaft 62 cooperates with the regulating valve 25, the right side of the rotating shaft 62 is provided with a stopper 63, the left side of the rotating shaft 62 is wound with a fourth spring 64, and the left side of the second twisting block 61 A limit rod 65 is provided, and a limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com