Self-checking type C-shaped steel forming machine and using method thereof

A technology of forming machine and C-shaped steel, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as reducing work intensity, and achieve the effect of reducing work intensity, avoiding eye fatigue, and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

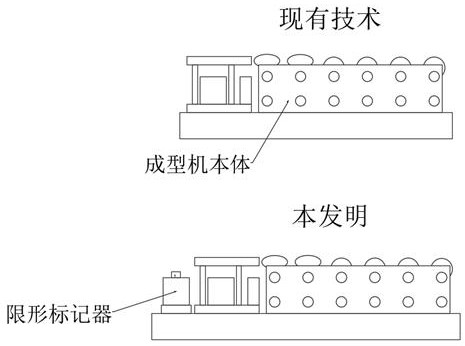

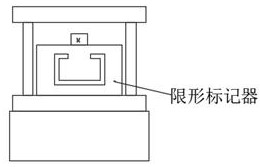

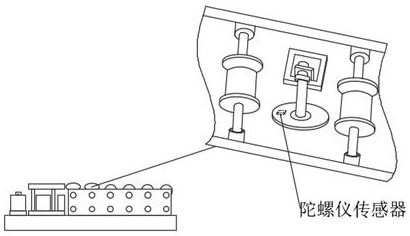

[0049] see Figure 1-10 , a self-inspection type C-shaped steel forming machine, including the forming machine body, please refer to image 3 , 10 , the body of the forming machine includes multiple groups of hemming rollers arranged inclinedly, and each hemming roller is provided with a gyro sensor inside, and the gyro sensor is electrically connected to the PLC control cabinet of the forming machine (as the prior art), the forming machine The discharge end of the body is provided with a limited shape marker, and an infrared sensor is installed at the feed inlet of the limited shape marker (because it is the prior art, so the schematic diagram is not drawn), and an alarm is connected to the infrared sensor. When the infrared sensor does not detect that the C-shaped steel enters the shape-limiting marker, the alarm will sound an alarm, indicating that the specifications of the C-shaped steel are unqualified, and there is a problem with the surface forming machine, so it is ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com