Patents

Literature

61results about How to "Avoid eye strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

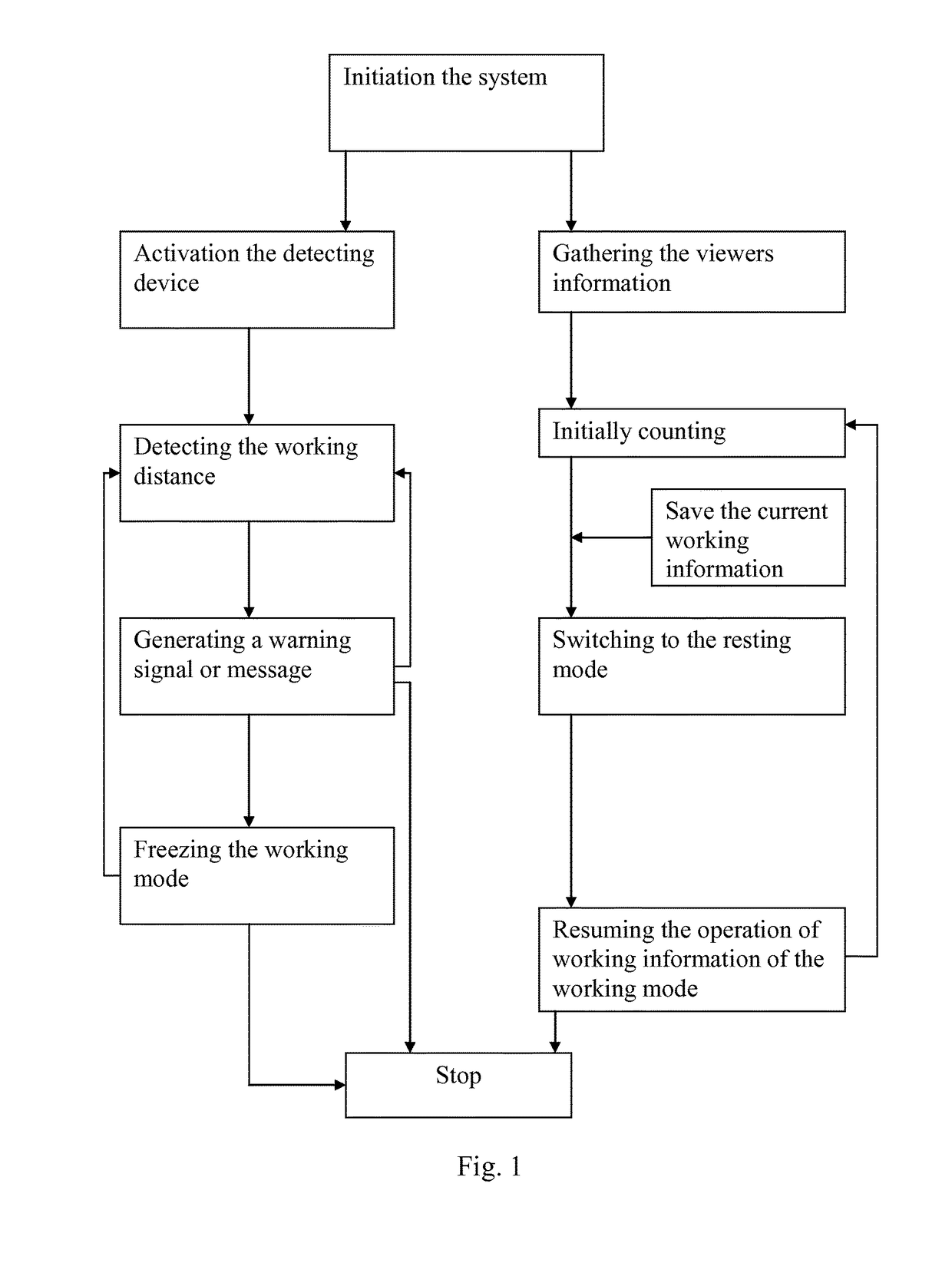

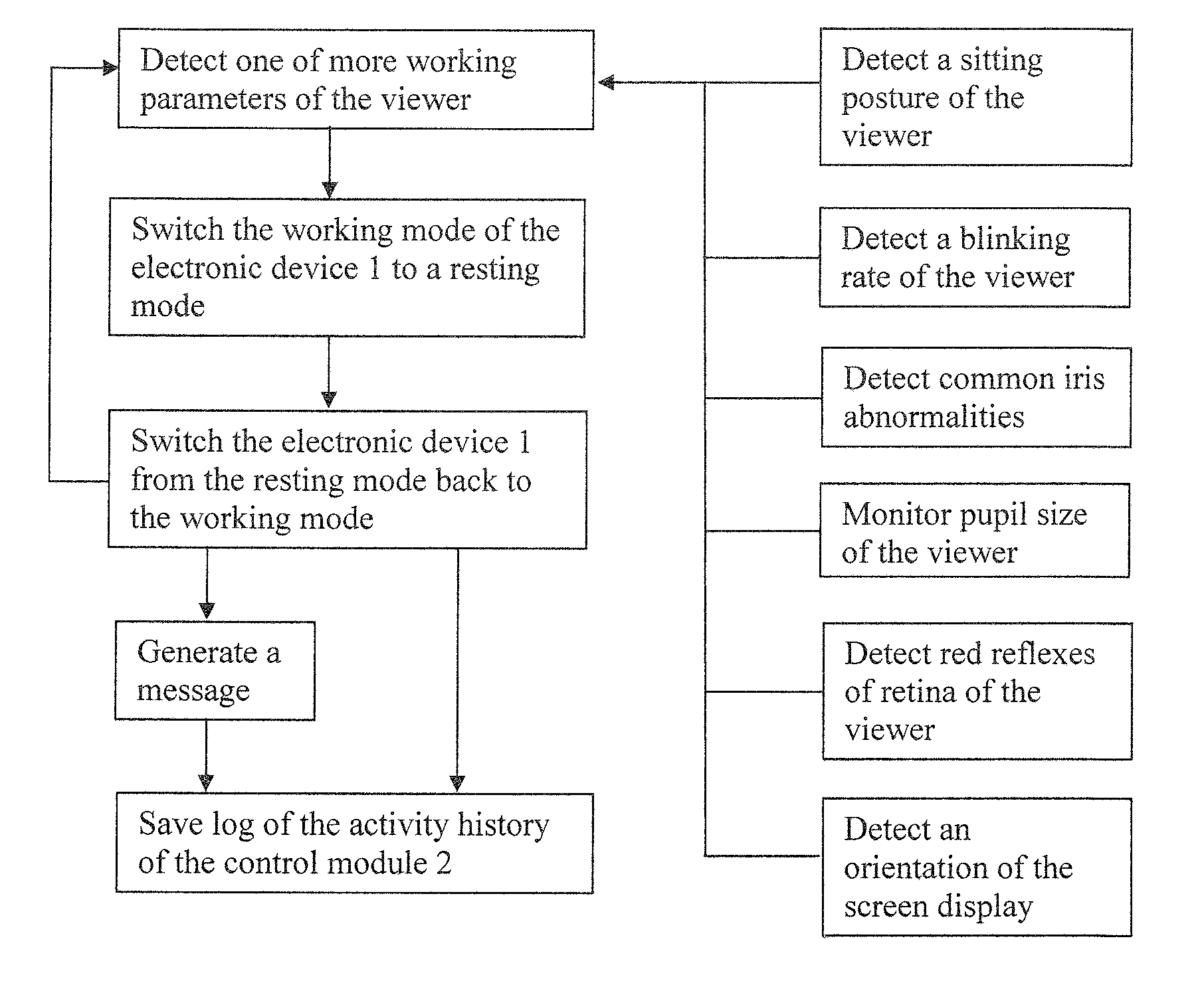

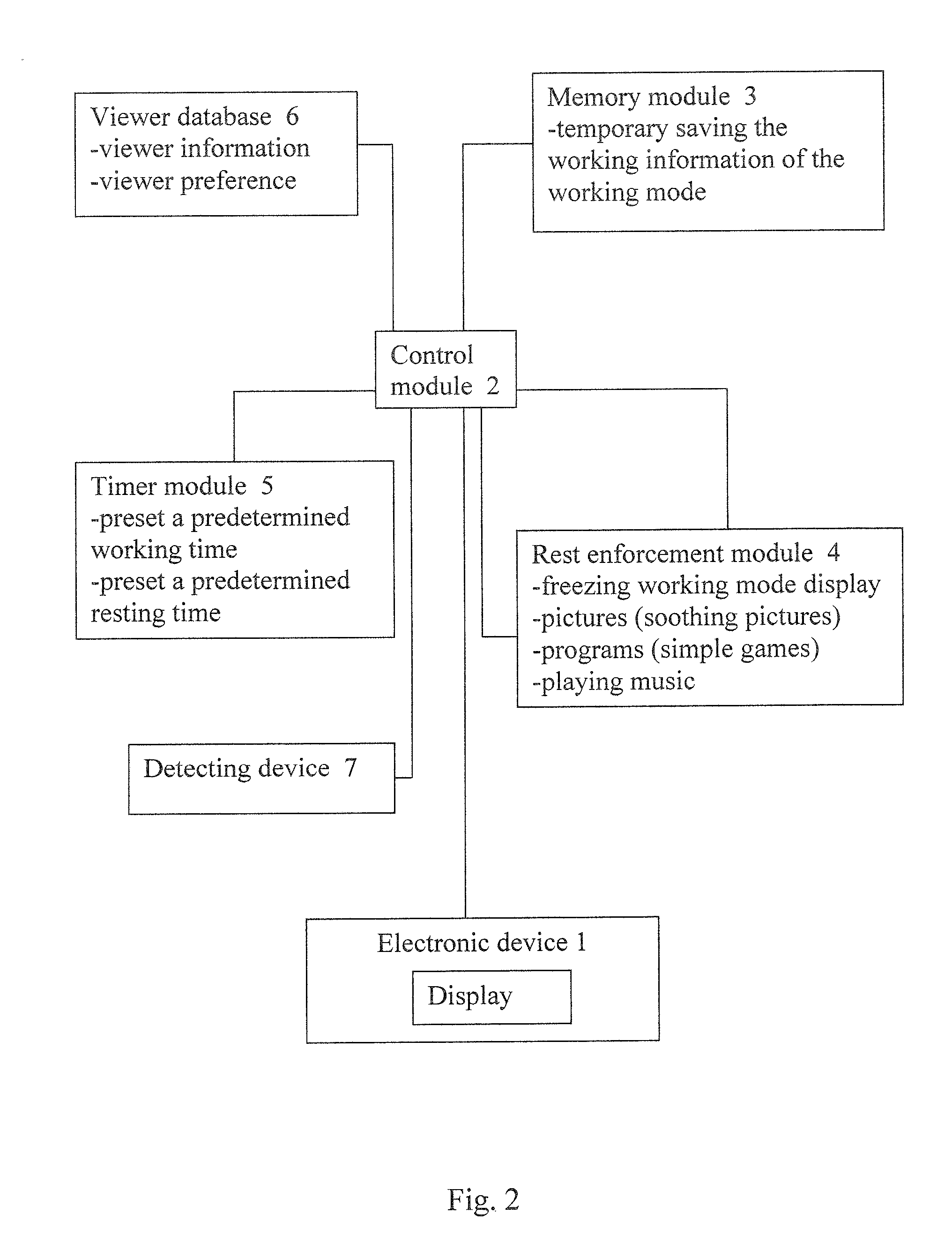

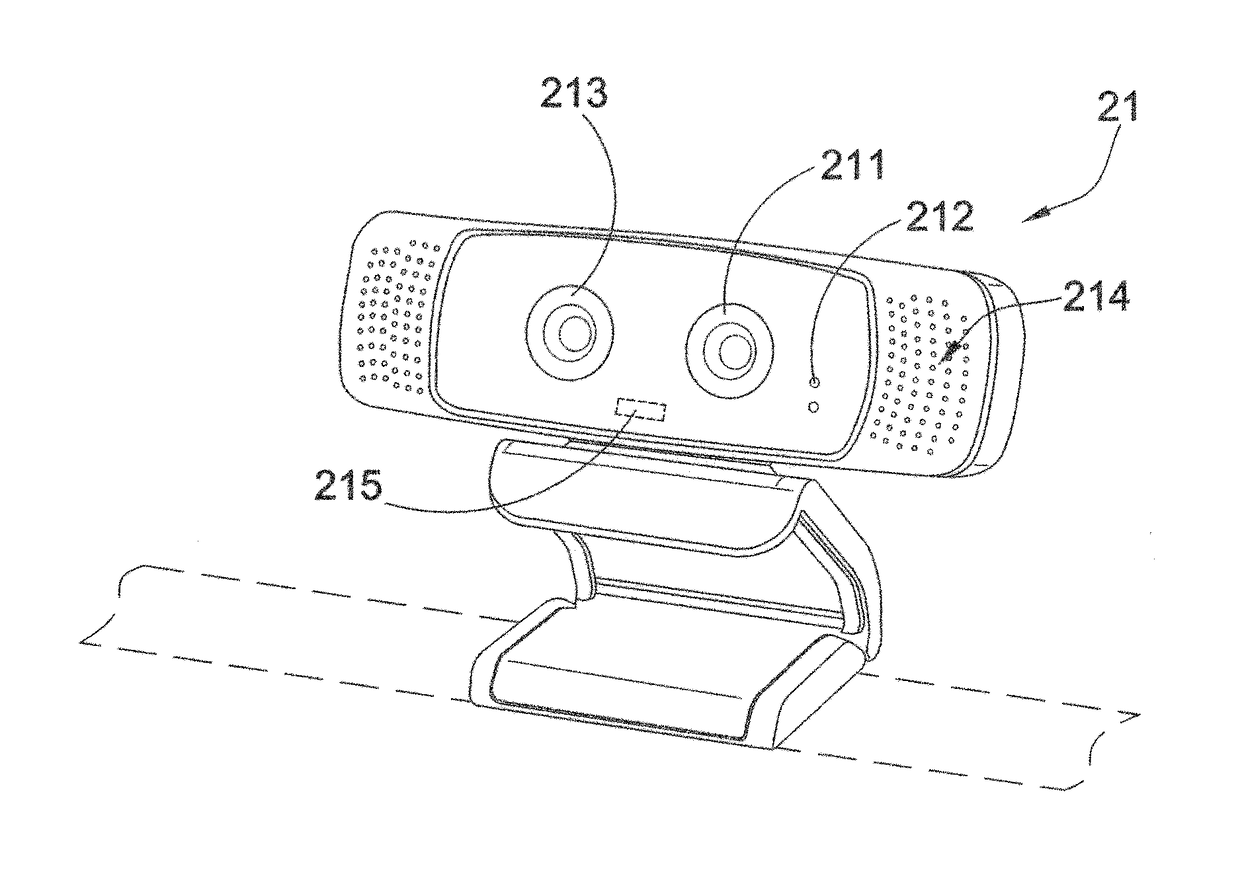

Vision protection method and system thereof

ActiveUS20110279277A1Avoid eye strainIndoor gamesCathode-ray tube indicatorsWork patternComputer science

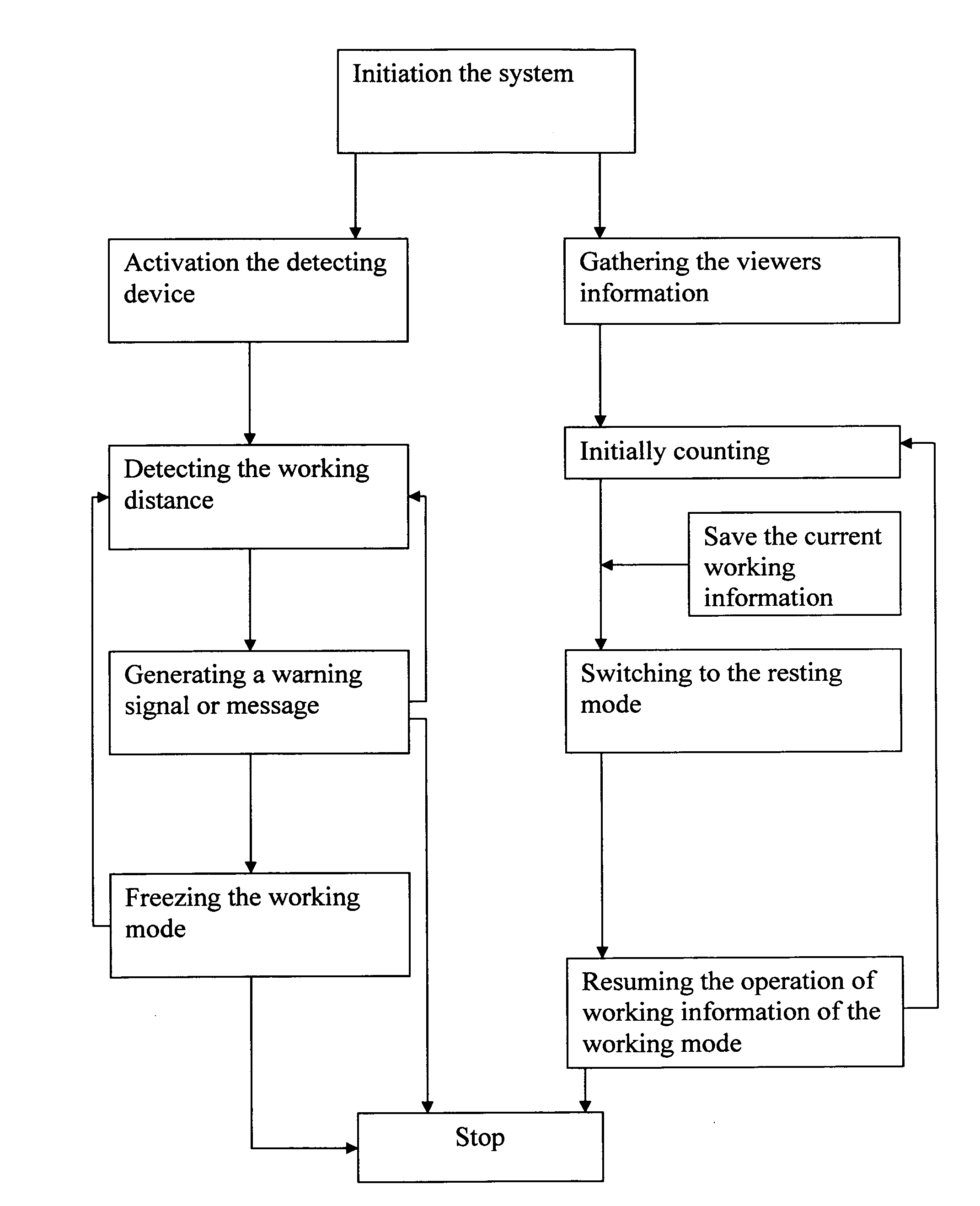

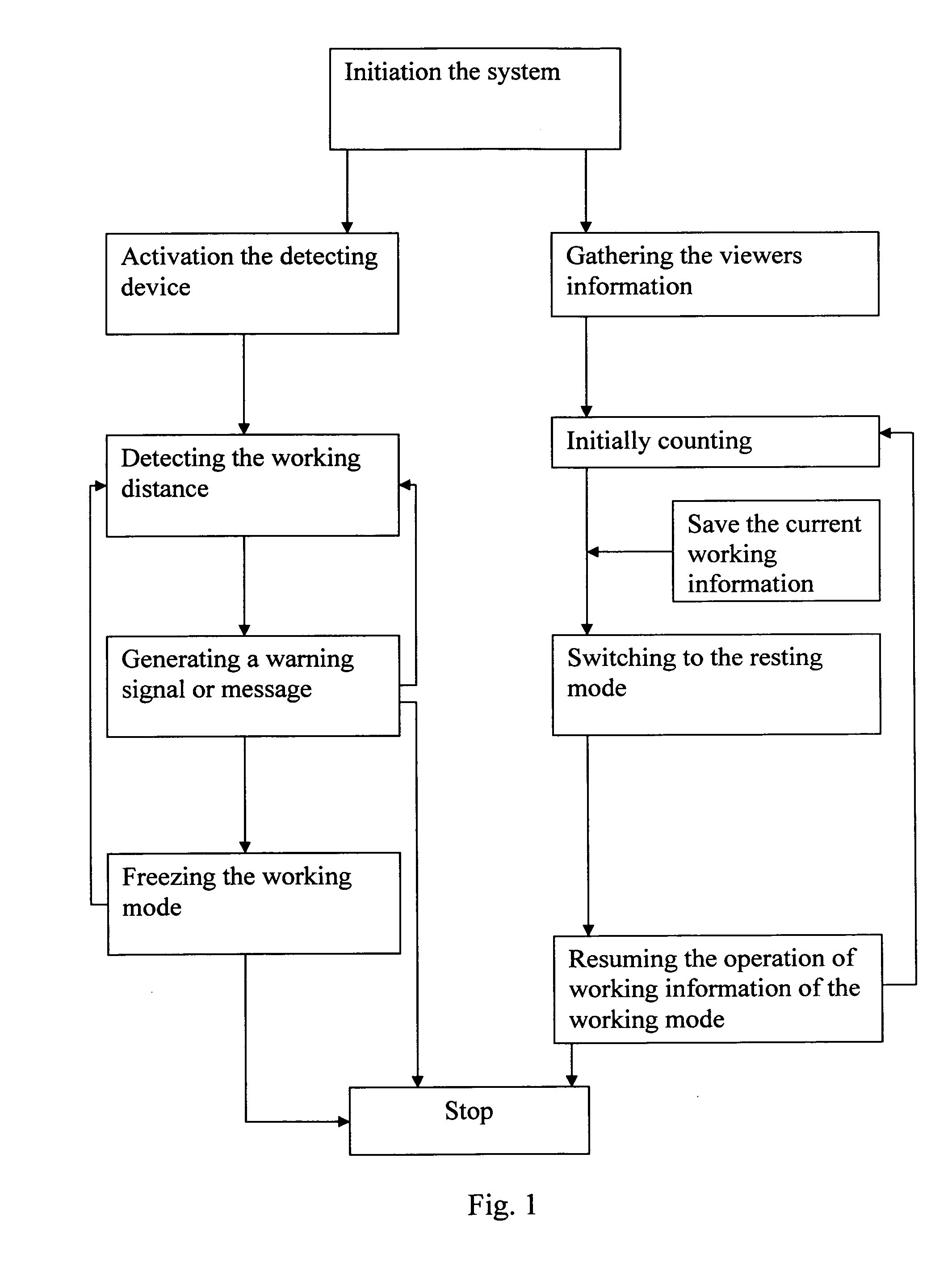

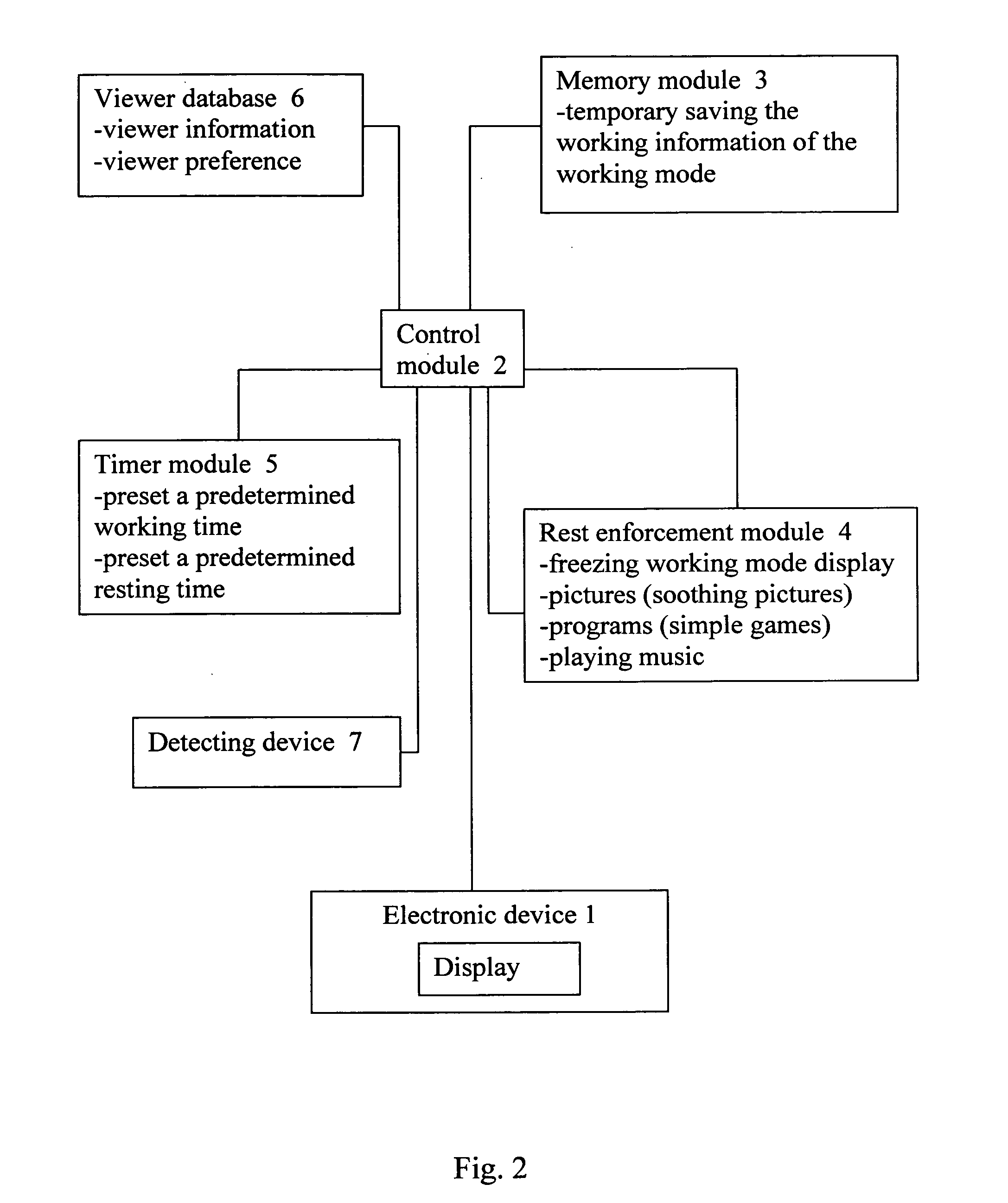

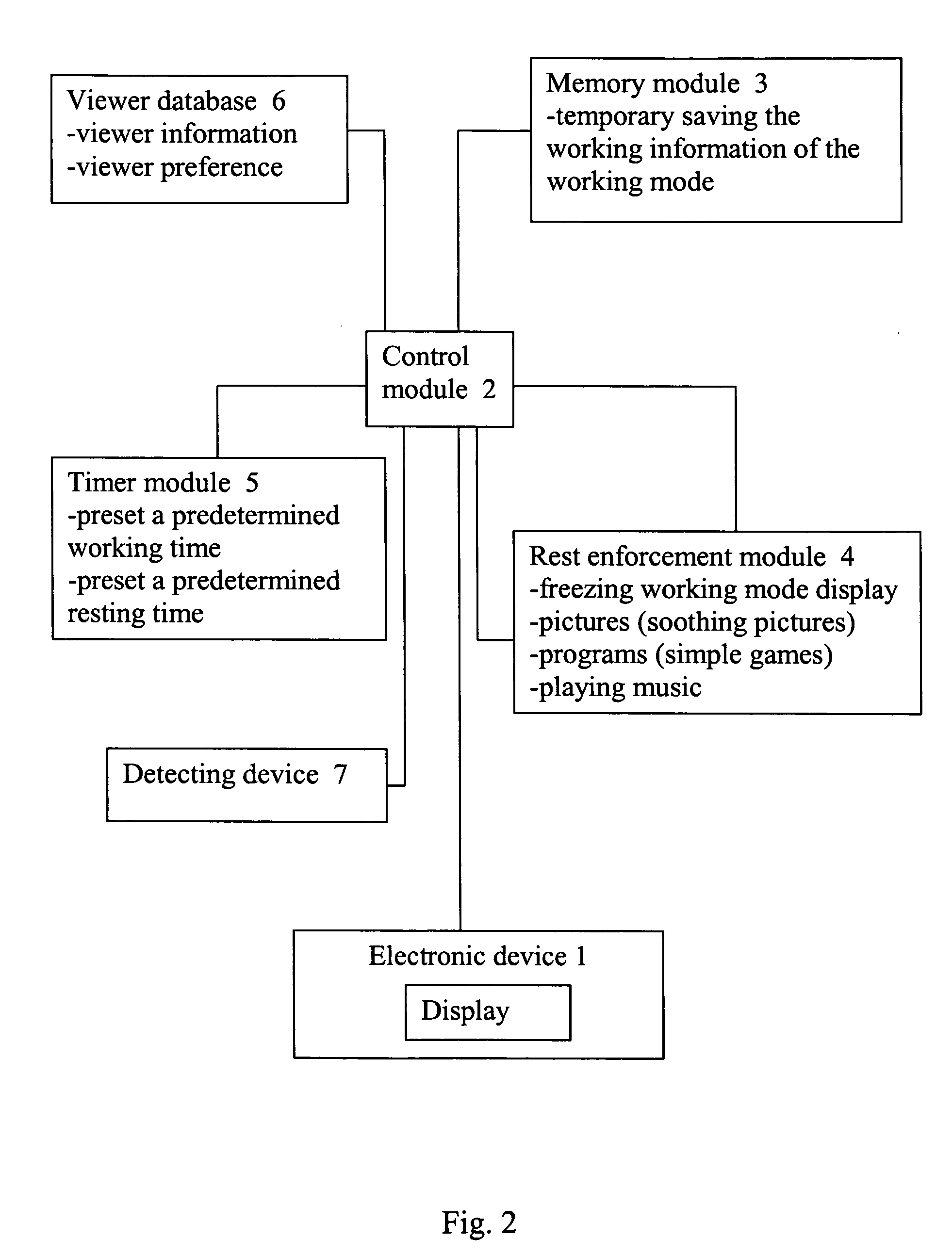

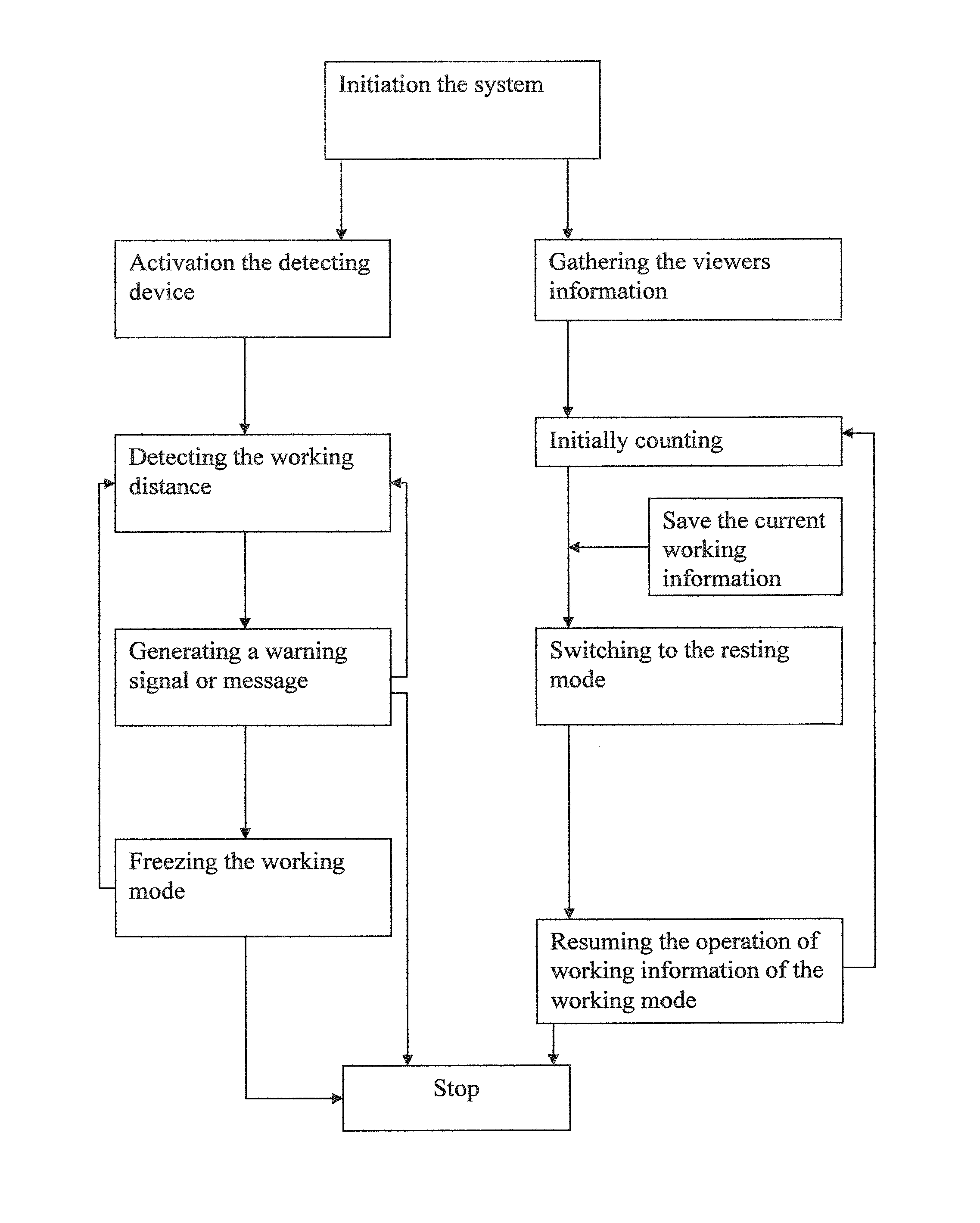

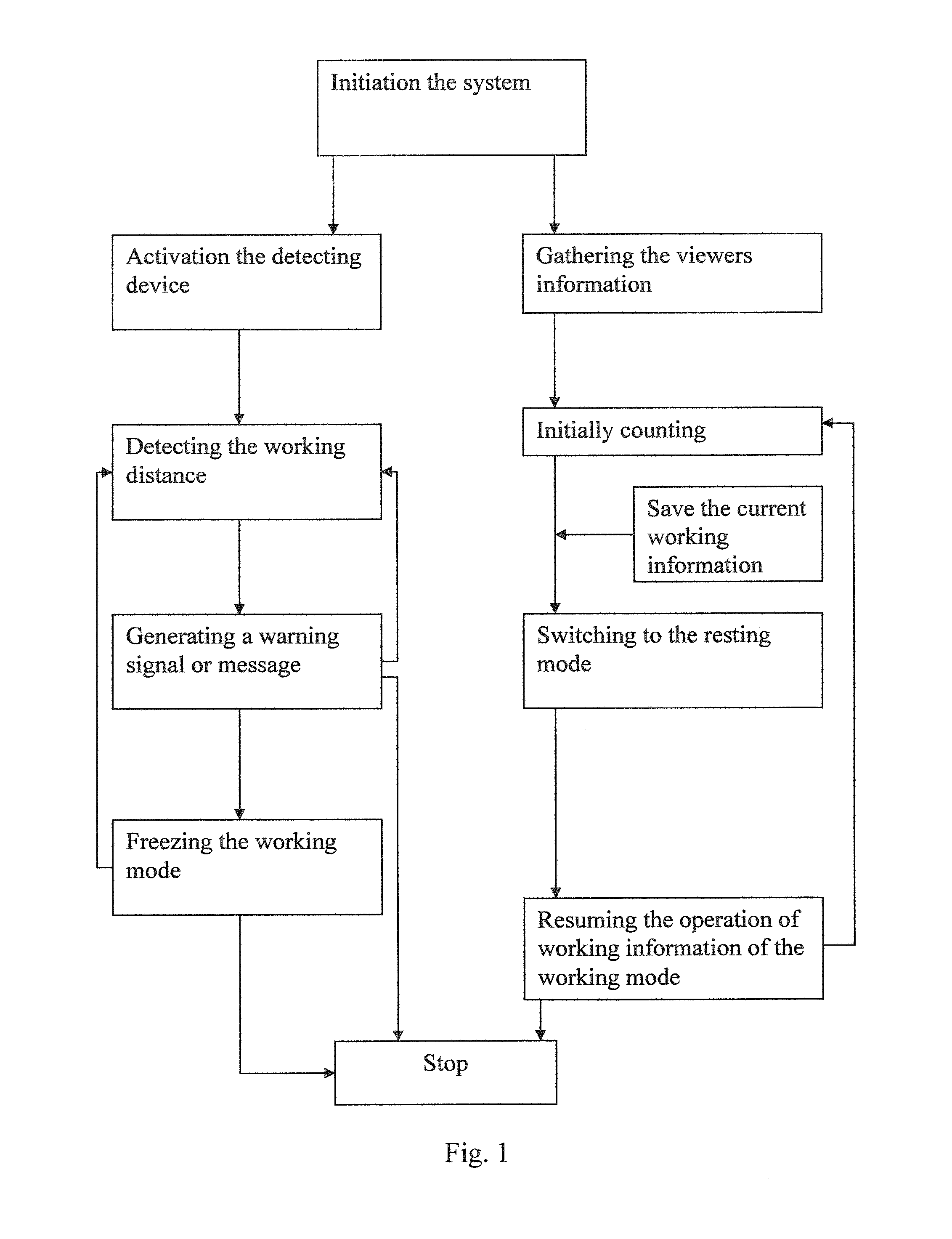

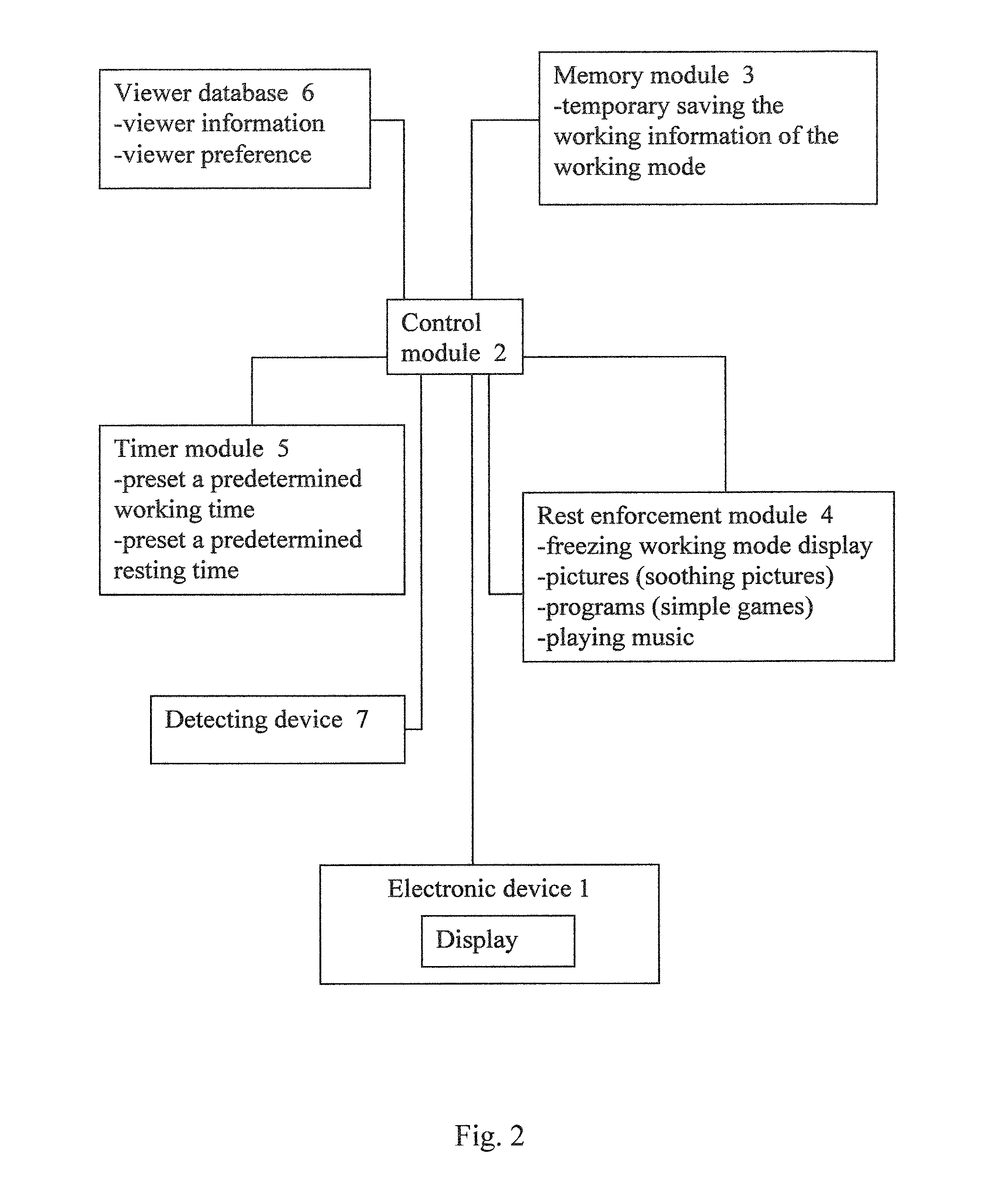

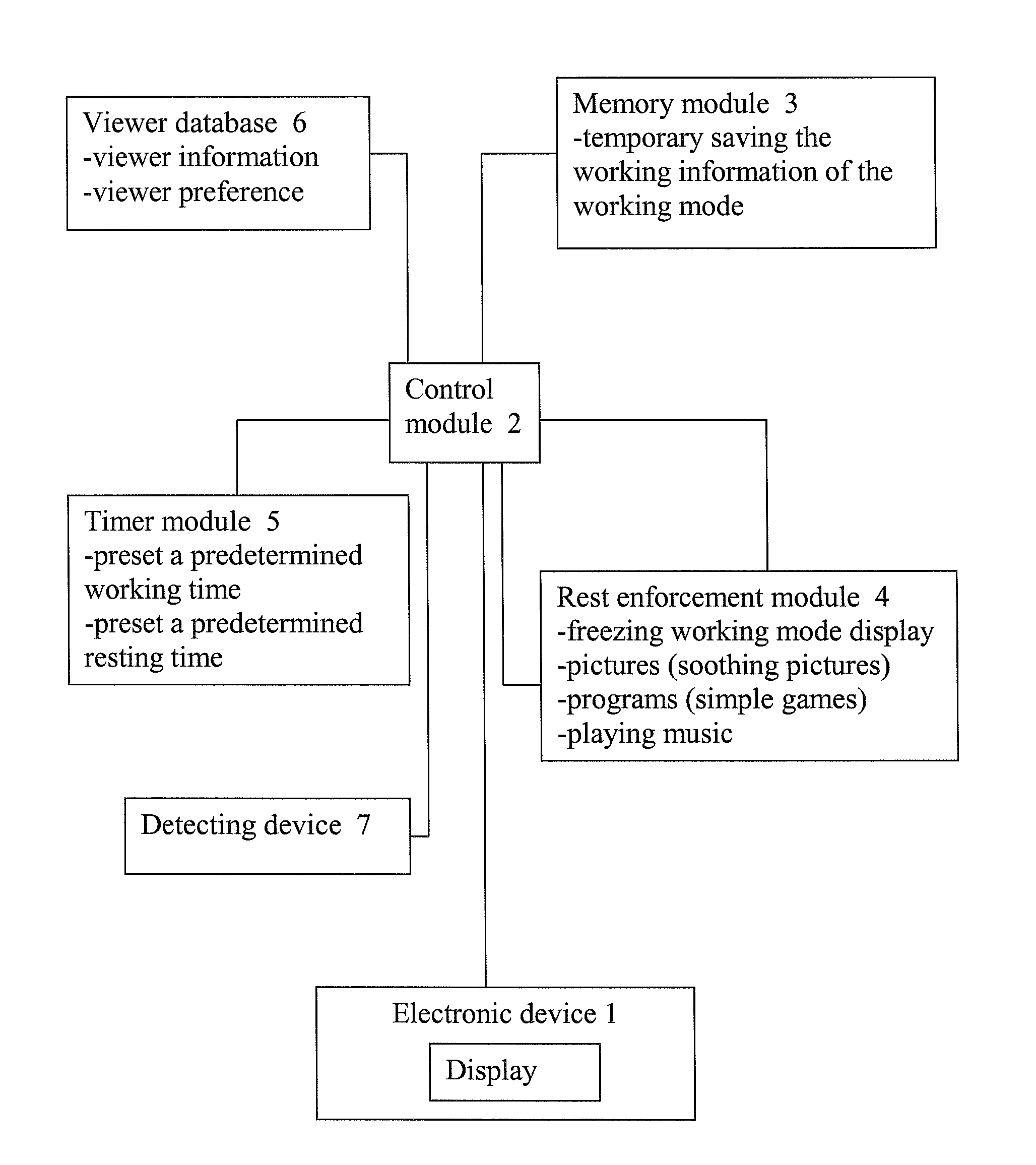

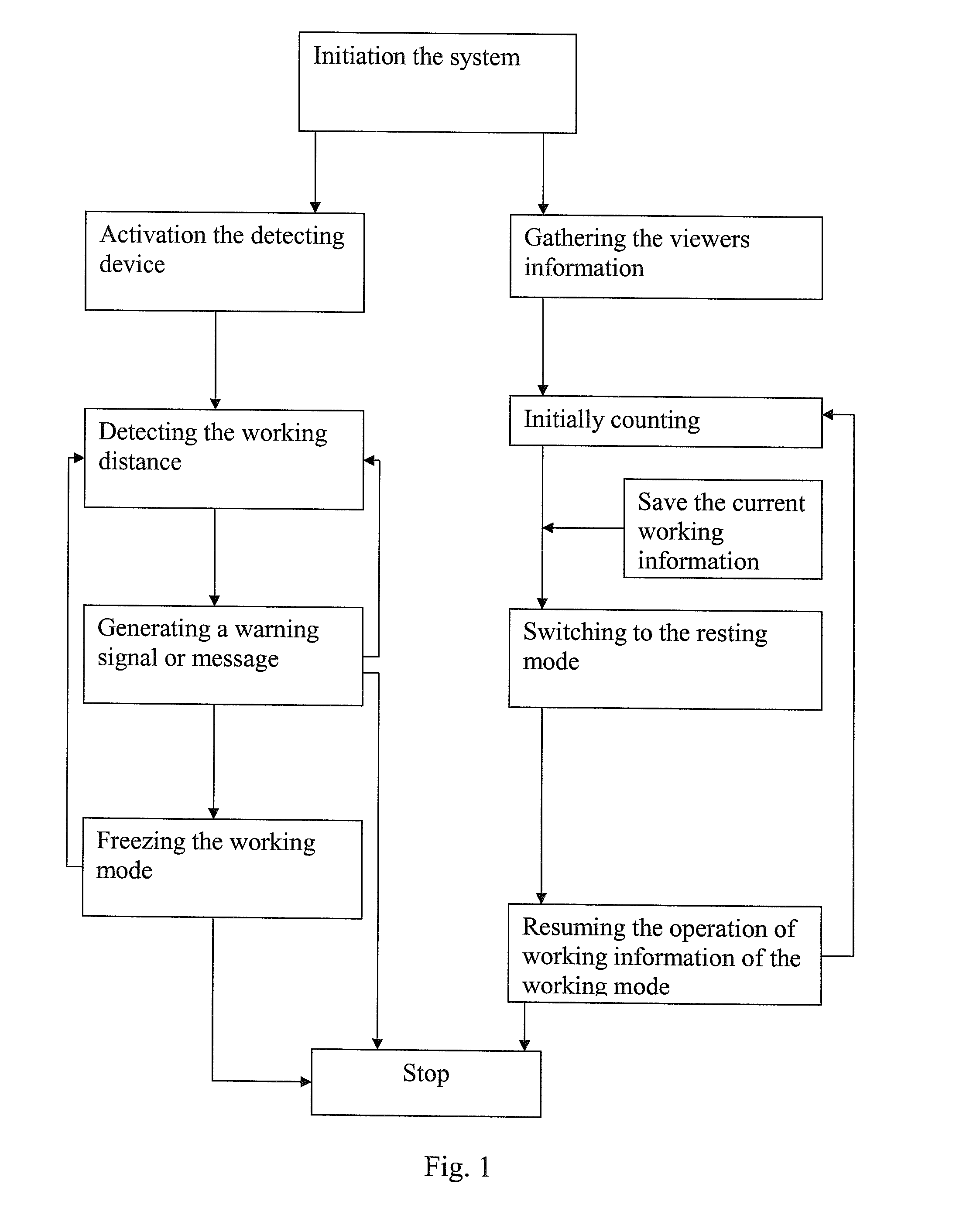

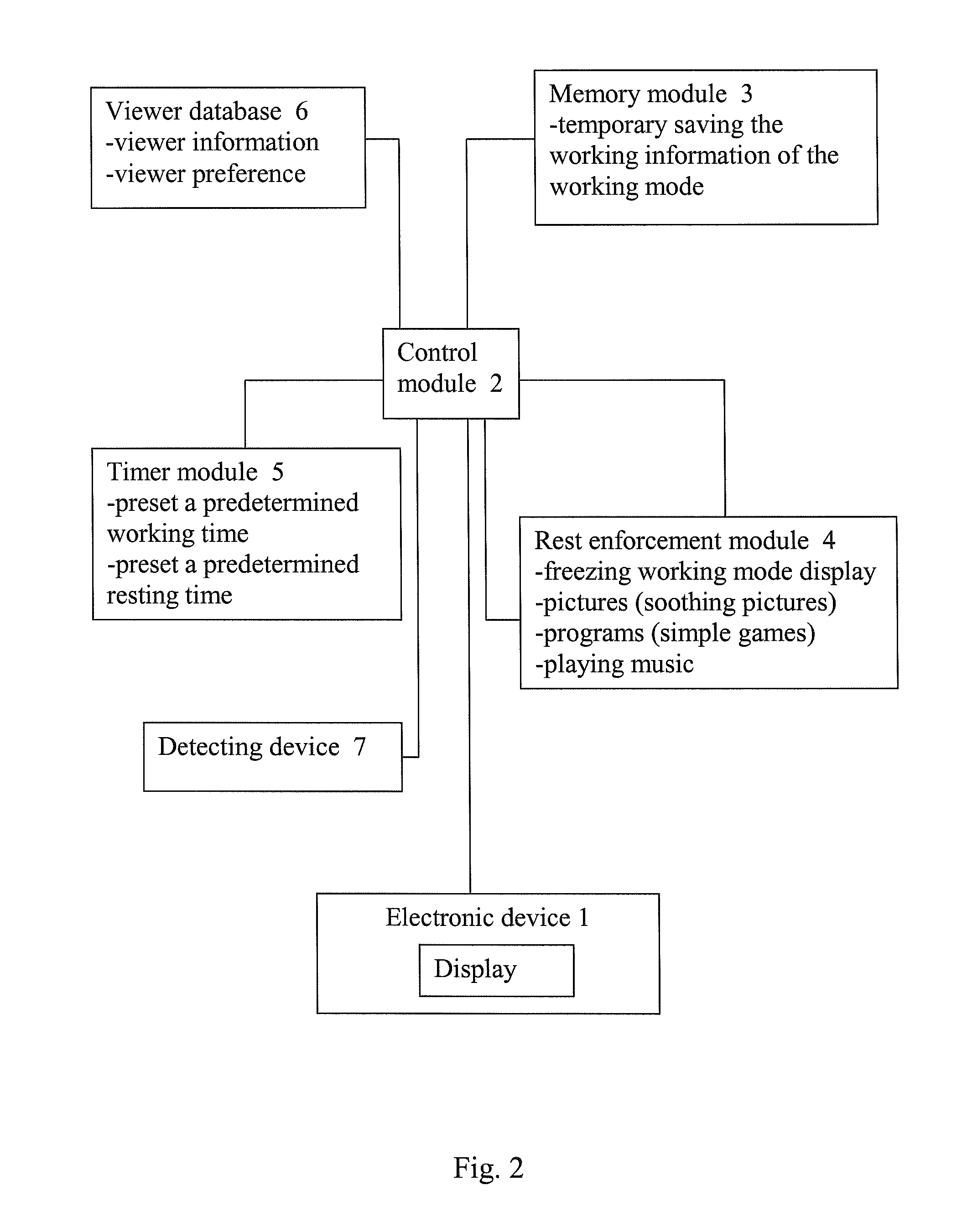

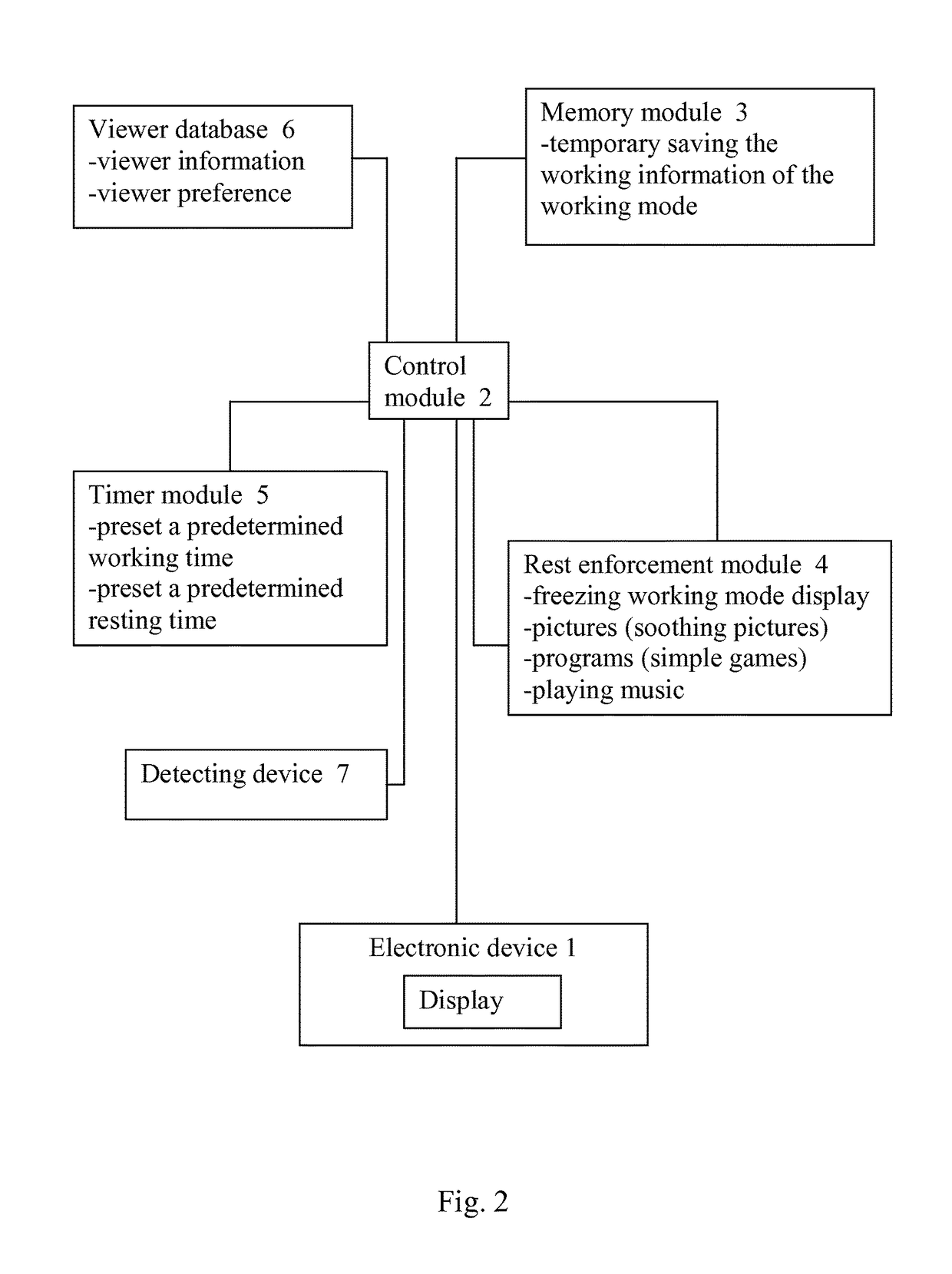

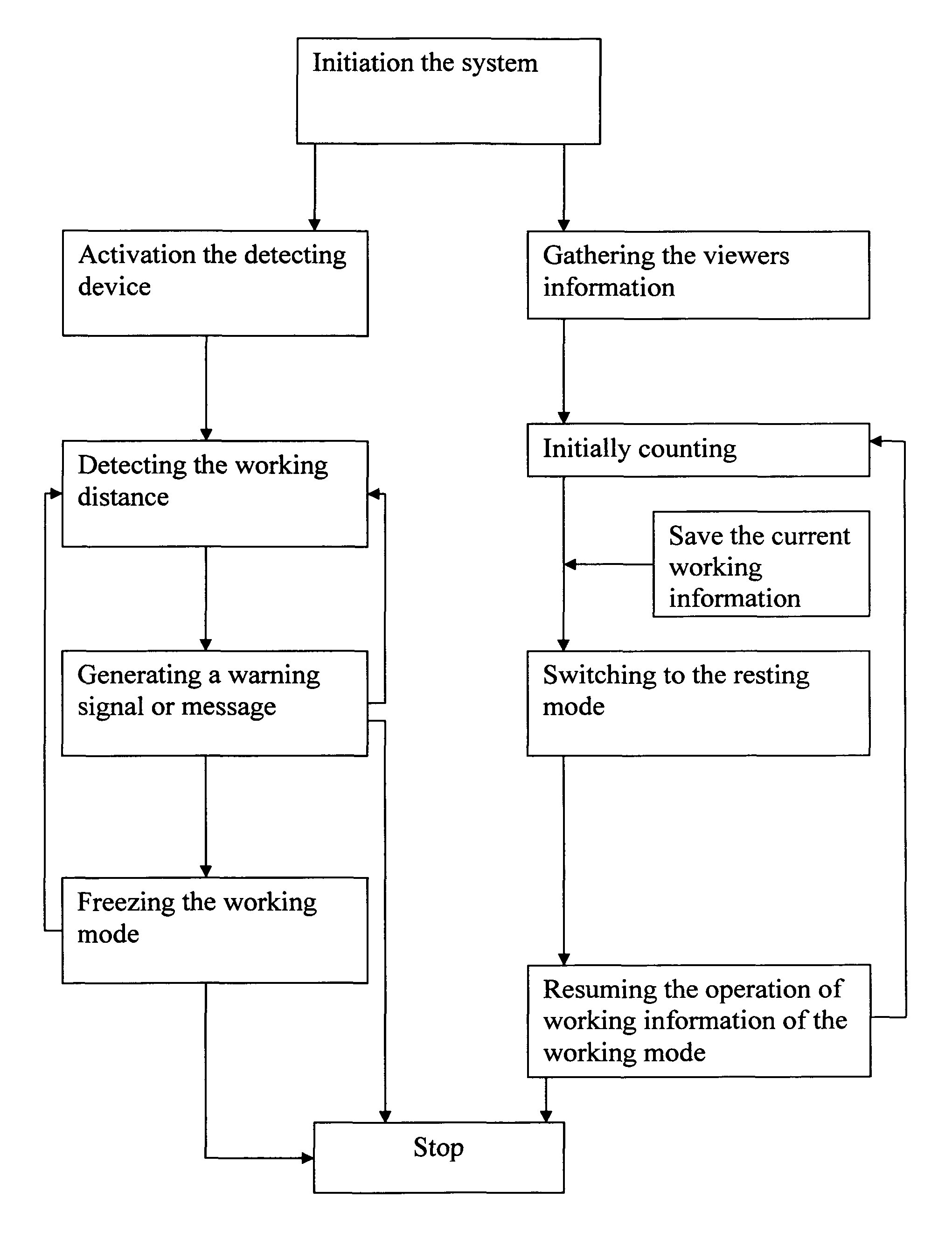

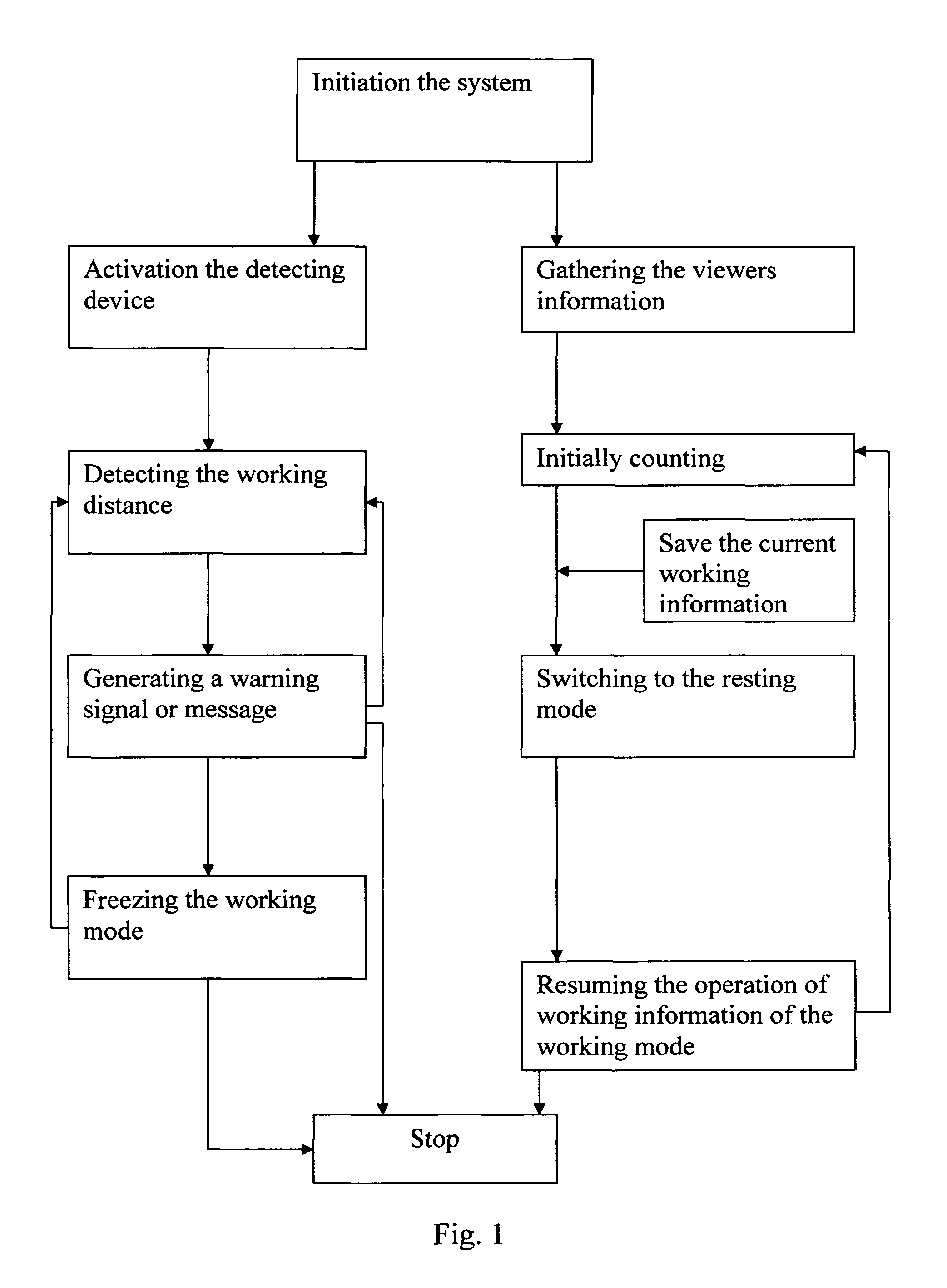

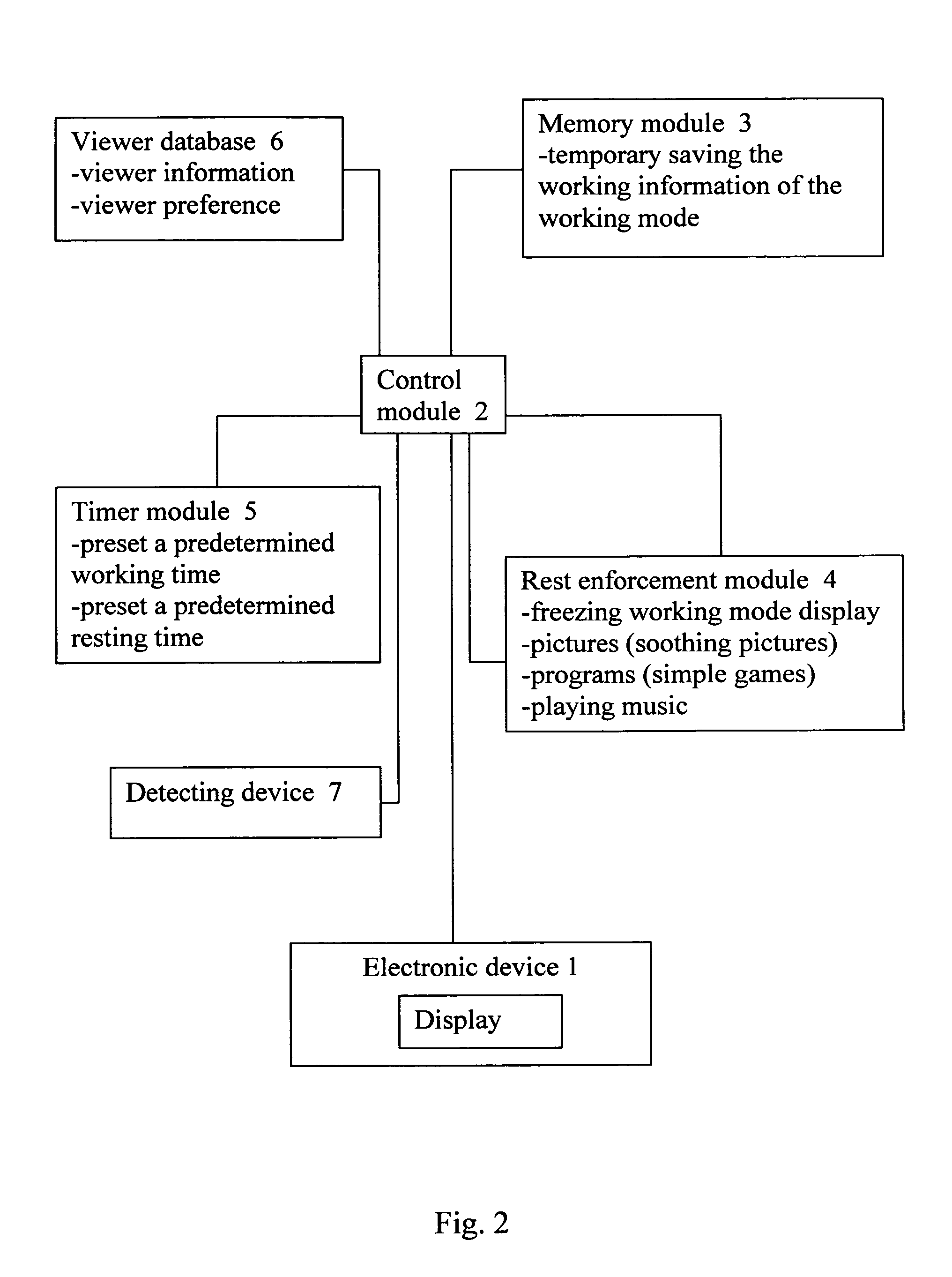

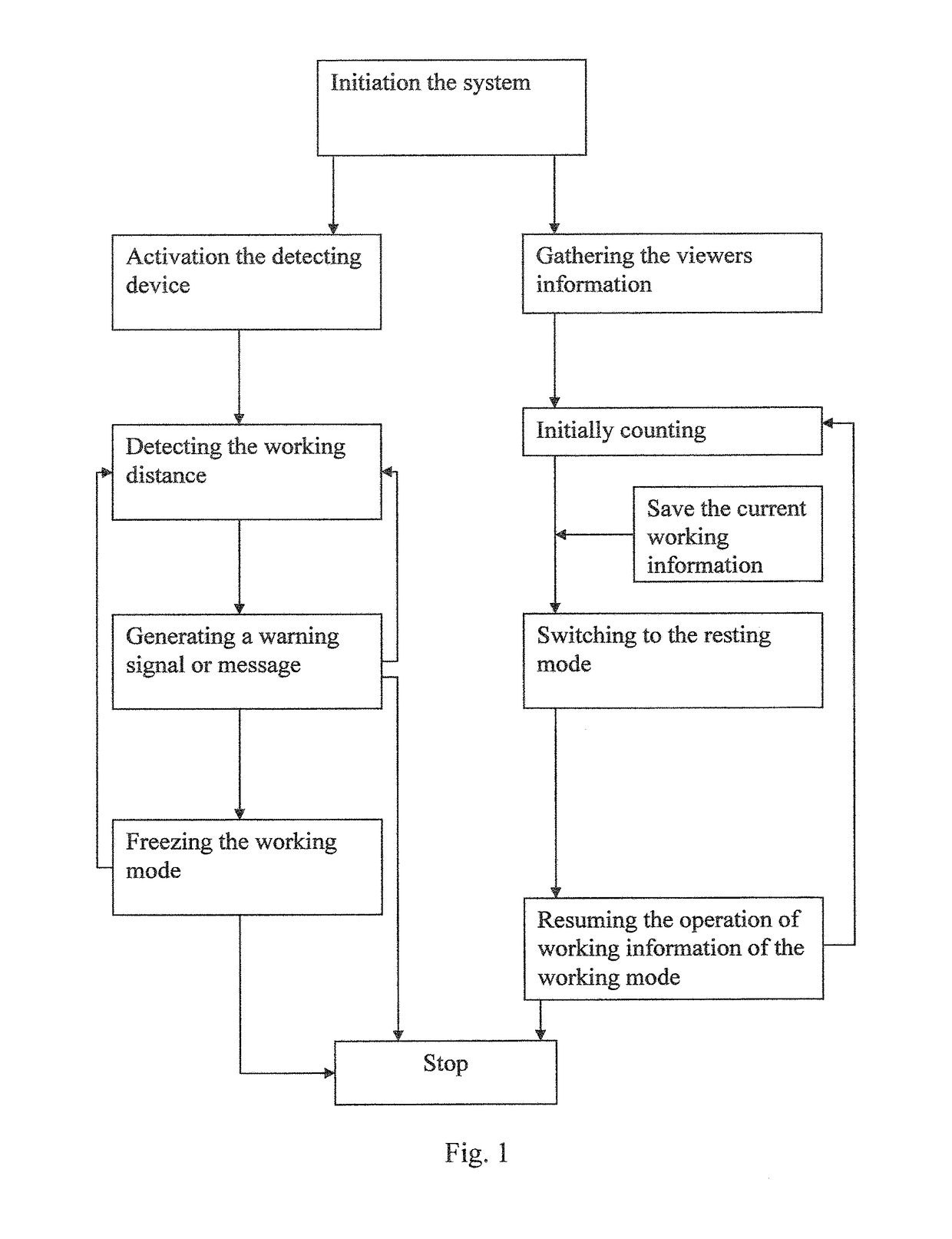

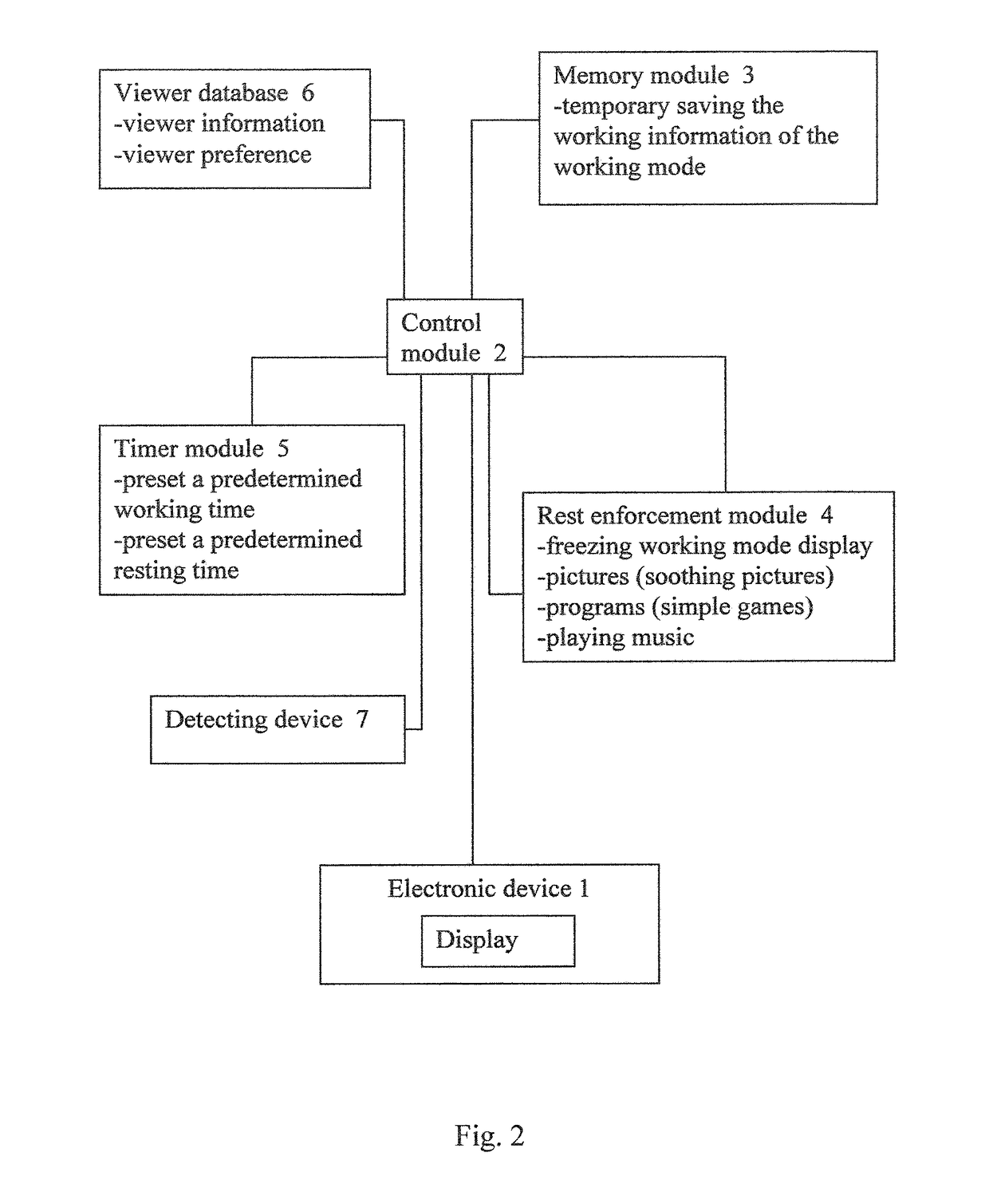

The vision protection method and system thereof is provided to ensure a viewer to rest his / her eyes after viewing on an electronic device for a certain period, wherein the eyesight protection method includes the steps of detecting one of more working parameters of the viewer in responsive to a preset working threshold in a working mode of the electronic device during the viewer is working on a current work displaying by the electronic device; switching the working mode of the electronic device to a resting mode; and switching the electronic device from the resting mode back to the working mode to resume the display of the current work of the electronic device. Therefore, the viewer is enforced to rest his / her eyes after every certain period.

Owner:EYES4LIVES INC

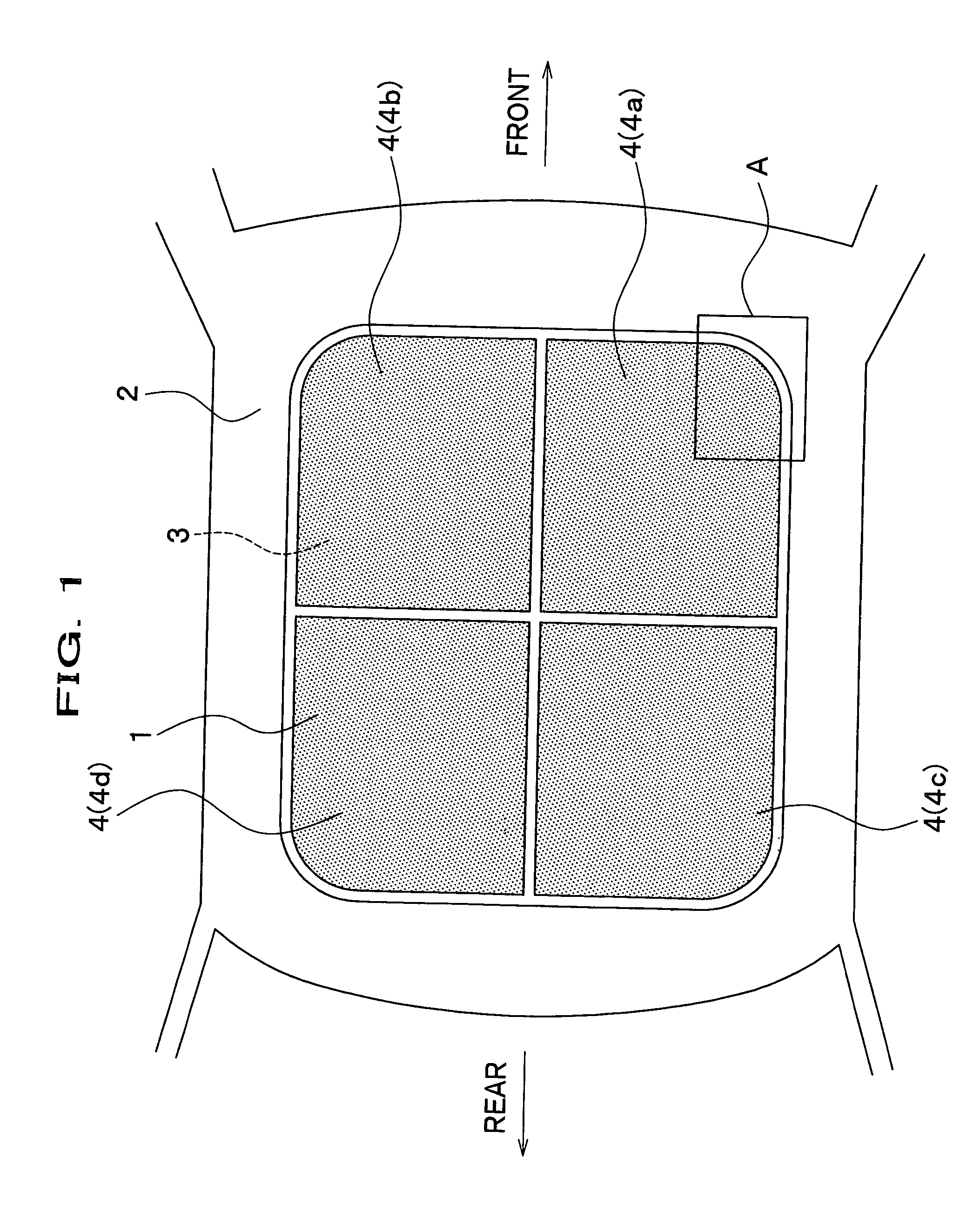

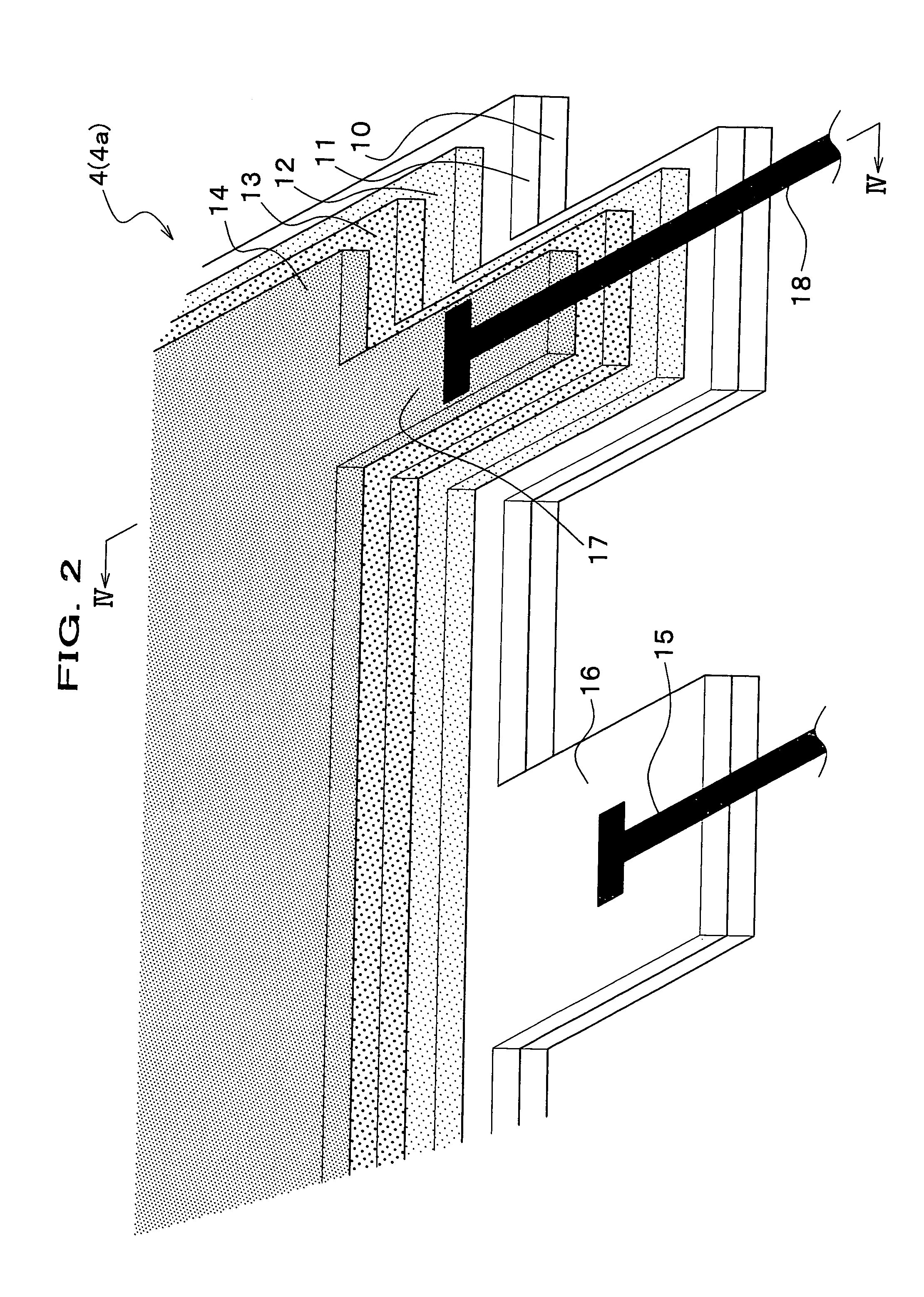

Sunroof panel apparatus for a vehicle

InactiveUS7118239B2Spoil beautyAvoid eye strainPlanar light sourcesOptical signallingElectricityEngineering

Owner:YACHIYO IND CO LTD +1

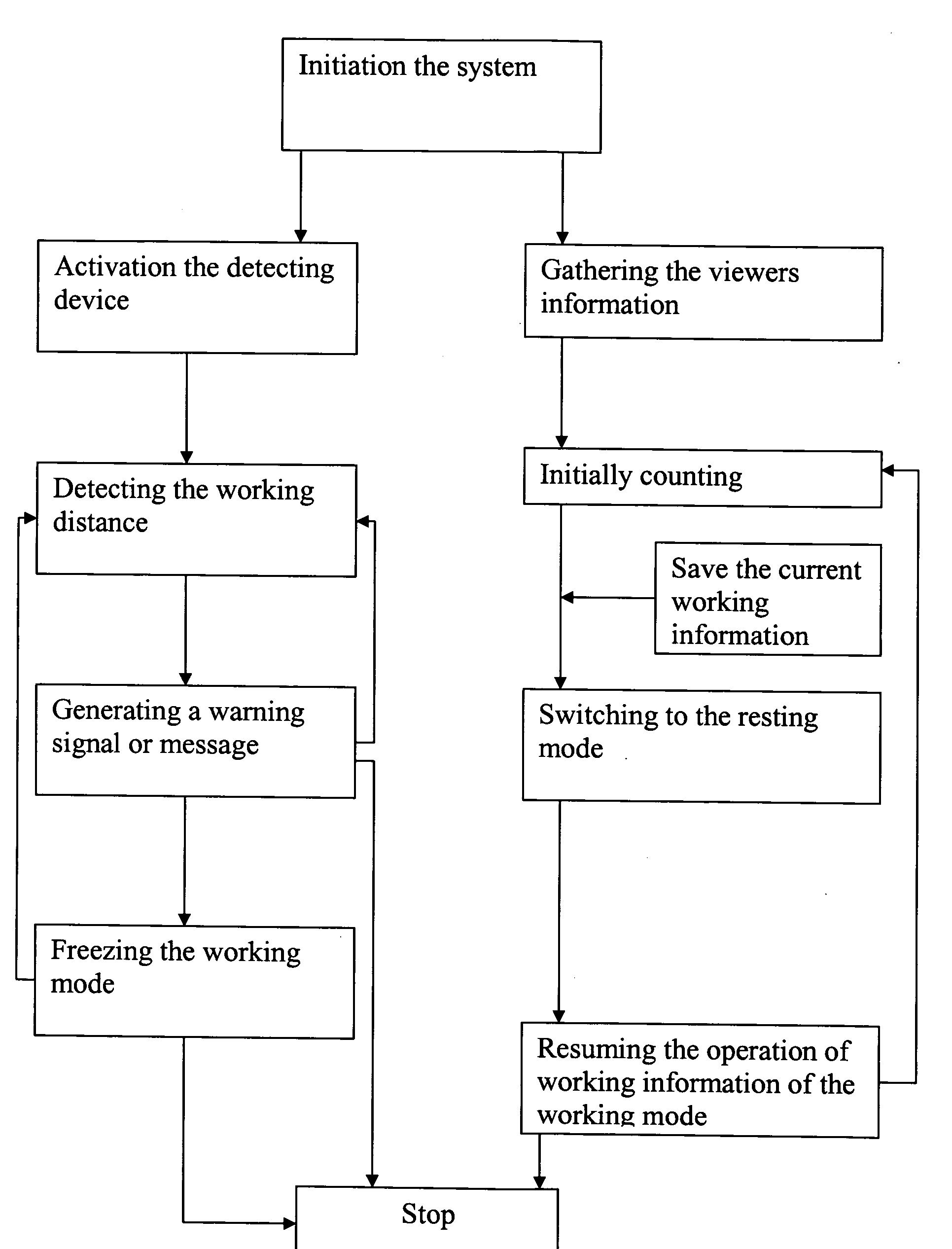

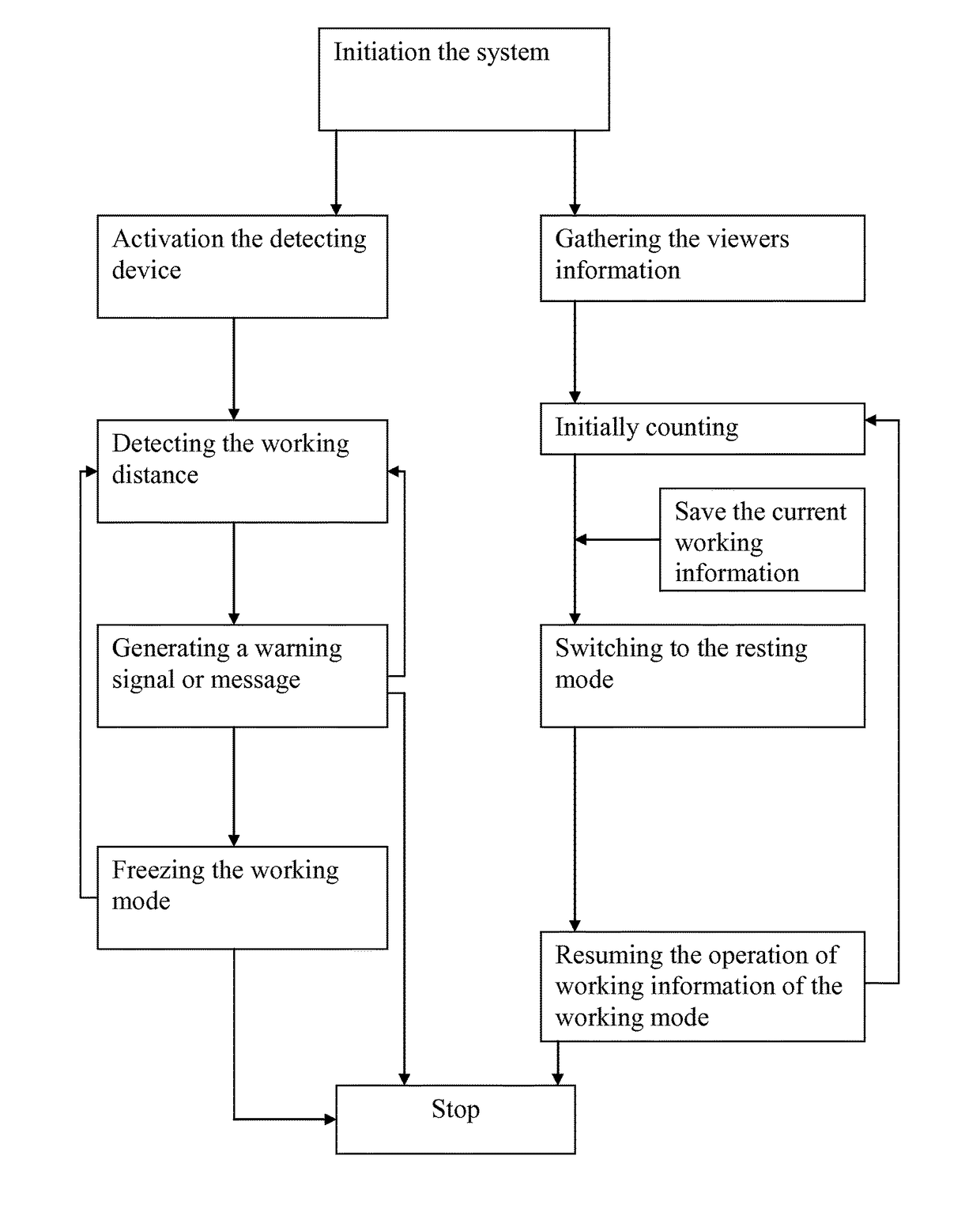

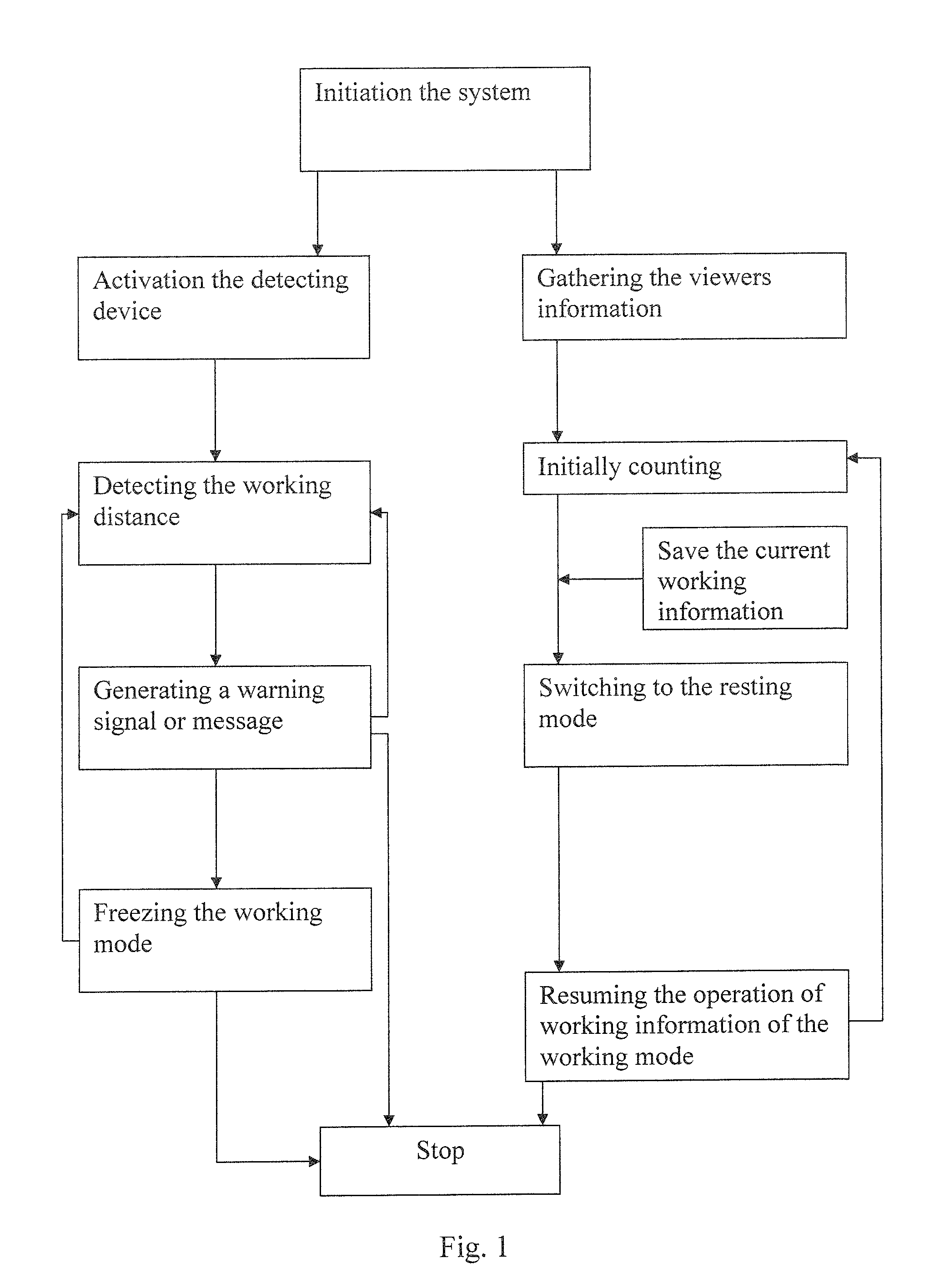

Vision protection method and system thereof

ActiveUS20100123544A1Avoid eye strainElectric testing/monitoringCathode-ray tube indicatorsTemporary StoppingEngineering

The vision protection method and system thereof is provided to ensure a viewer to rest his / her eyes after viewing on an electronic device for a certain period, wherein the eyesight protection method includes the steps of initially counting down a predetermined working time of a working mode, switching the working mode to a resting mode to temporarily halt the current working mode of the electronic device, and resuming the operation of the working mode that the viewer was previously working on. In that manner, the viewer is enforced to rest his / her eyes after every certain period.

Owner:EYES4LIVES INC

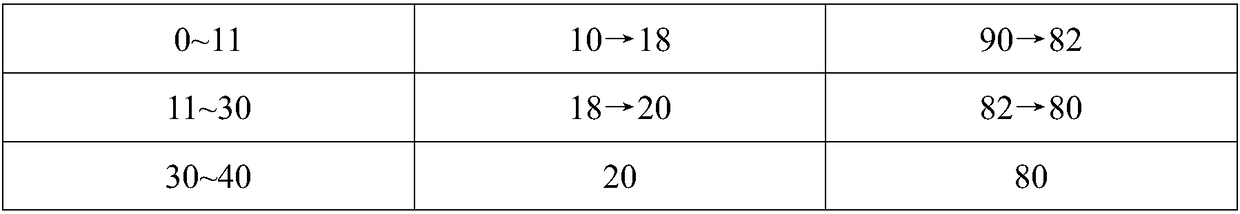

Display mode adjusting method of display device and display mode adjusting module thereof

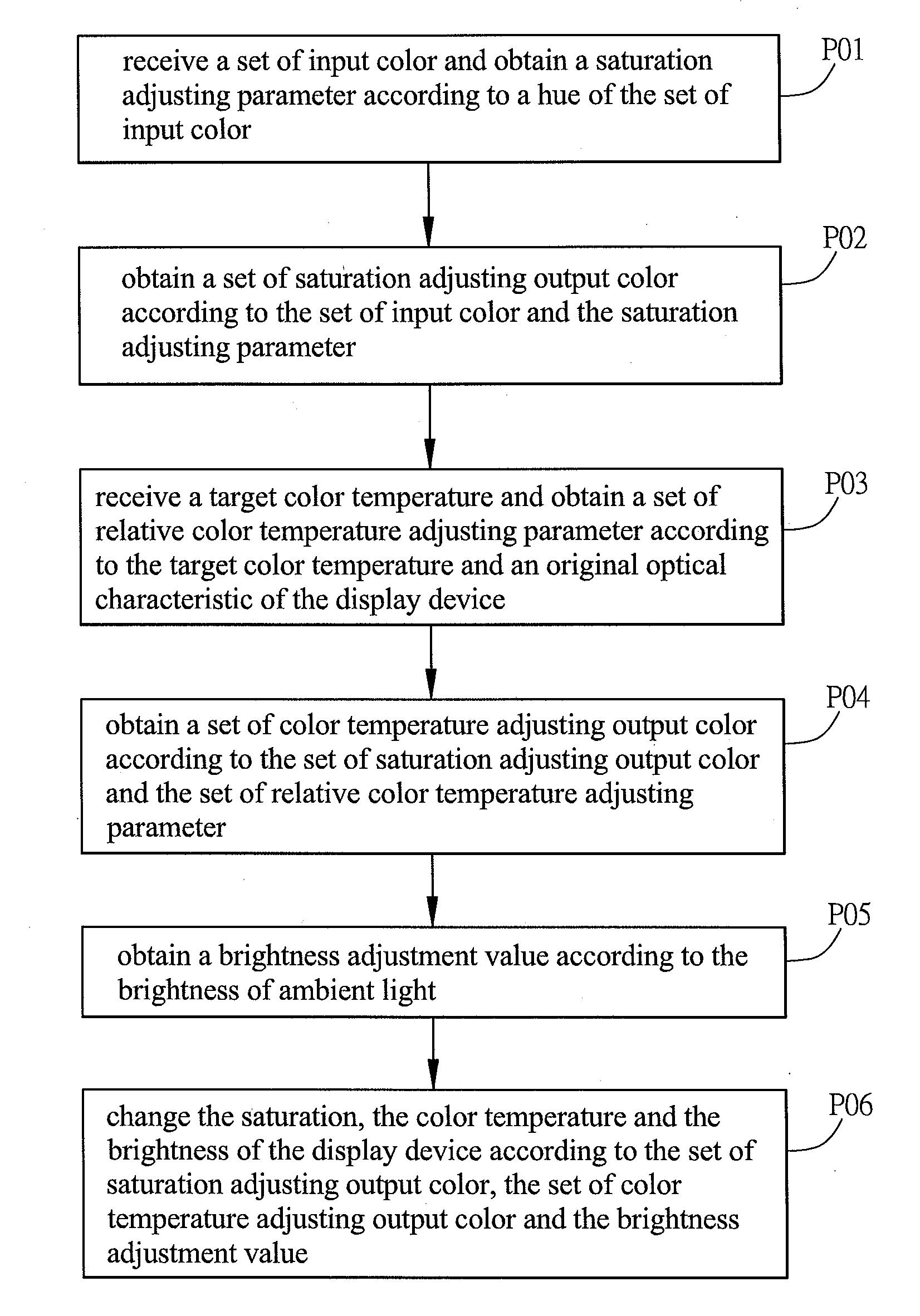

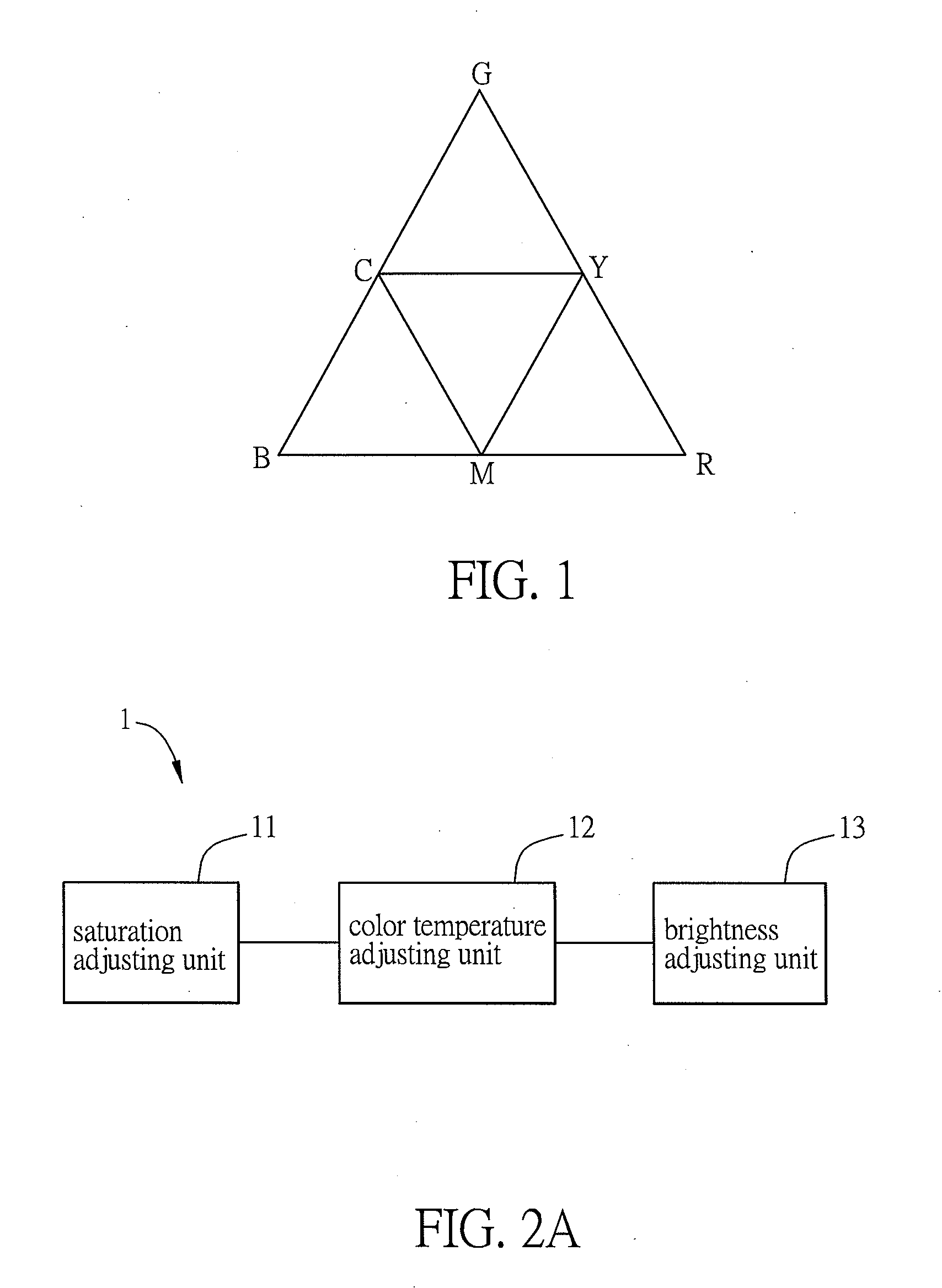

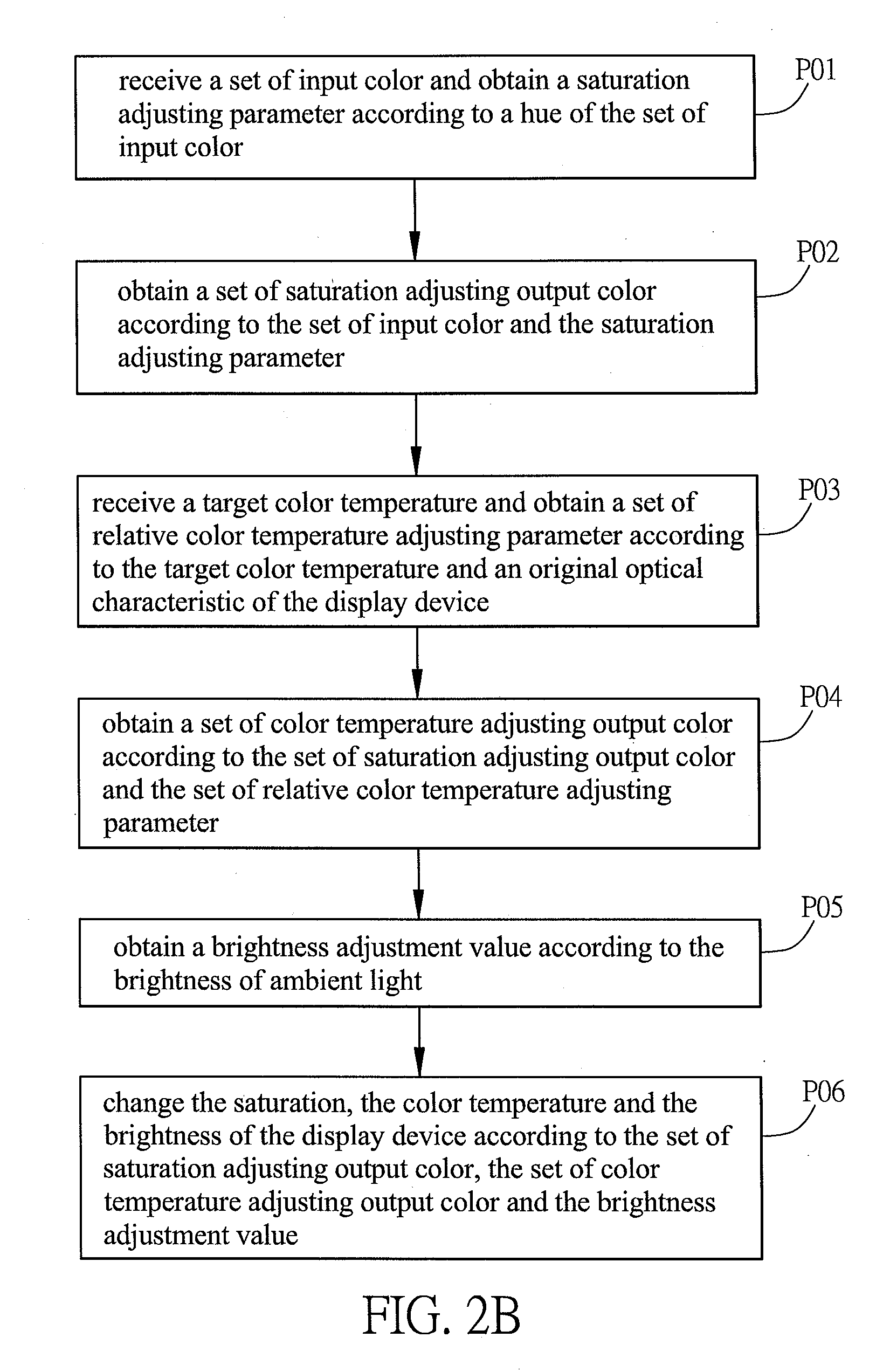

A display mode adjusting method and a display mode adjusting module executing the adjusting method are provided. The method includes the following steps: generating a saturation adjusting output color according to an input color to adjust the saturation; obtaining a relative color temperature adjusting parameter according to a target color temperature and an original optical characteristic of a display device; generating a color temperature adjusting output color according to the saturation adjusting output color and the relative color temperature adjusting parameter to adjust the color temperature; obtaining a brightness adjustment value according to the brightness of ambient light to adjust the brightness. Therefore, the display mode of the display device is adjusted to suitable for reading, which avoids the eyestrain when the users read for a long time.

Owner:ASUSTEK COMPUTER INC

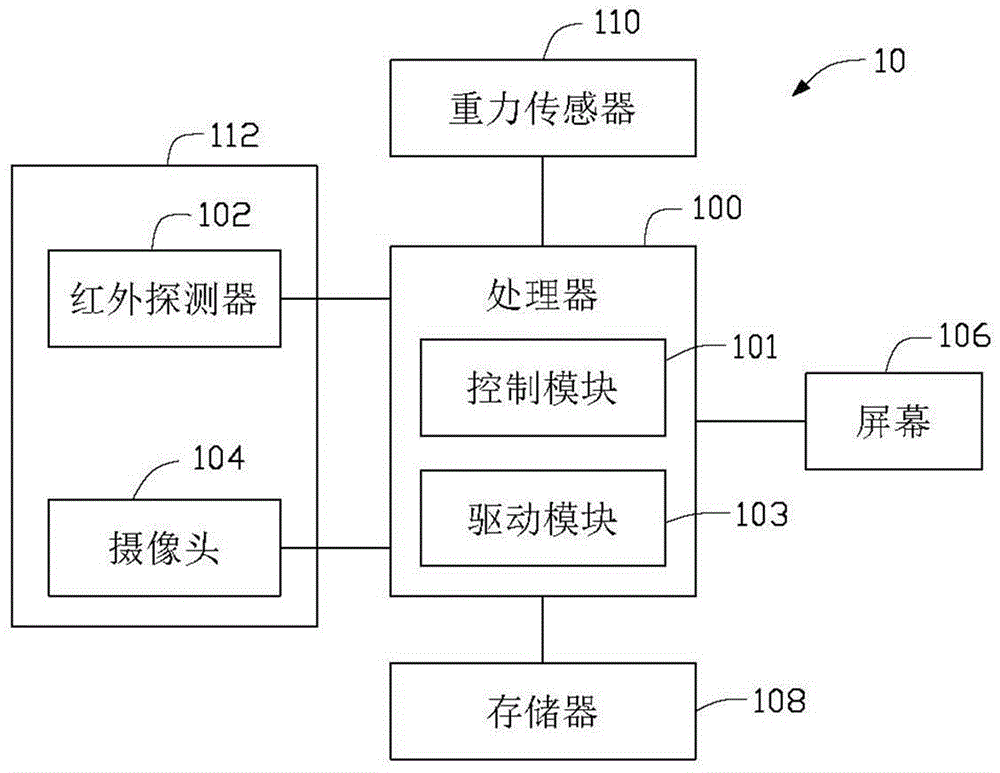

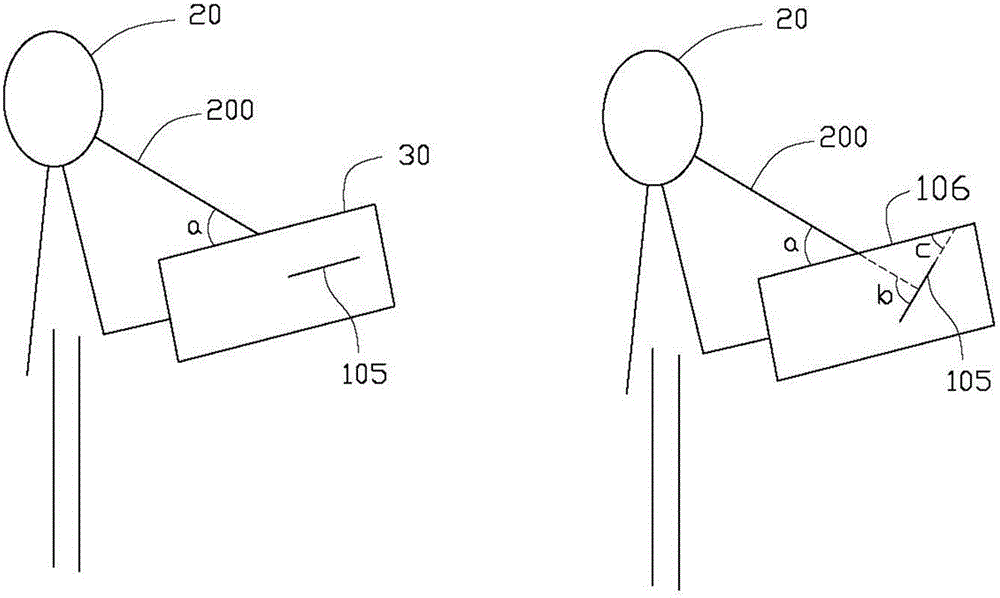

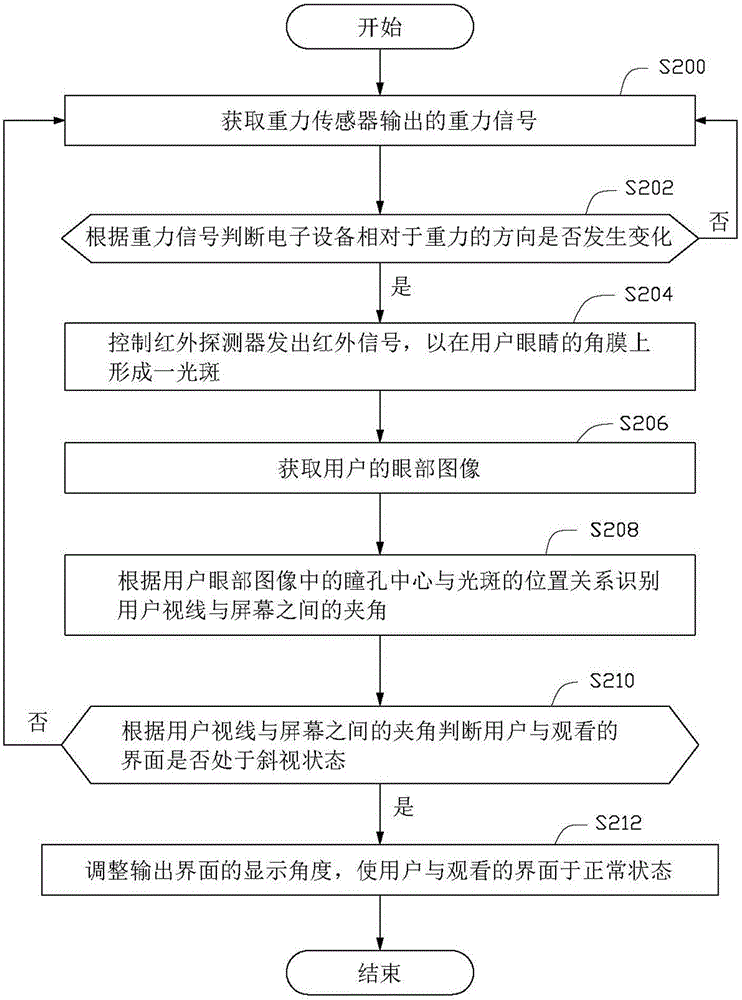

Electronic device and display adjustment method for electronic device

InactiveCN105988556AAvoid eye strainEasy to useInput/output for user-computer interactionGraph readingElectronic equipmentNormal state

An electronic device includes a screen for displaying an interface, a viewing angle detection device and a processor. The viewing angle detecting device is used for outputting an included angle between a user and the screen viewed. The processor is used to judge whether the user's line of sight and the interface viewed in the screen are in a squint state according to the angle; when the user's line of sight and the interface viewed in the screen are in a state of squint, the processor adjusts the screen interface Angle, so that the user's line of sight and the adjusted interface in the screen are in a normal state. The invention also provides a display adjustment method. The electronic device and method of the present invention can adjust the angle of interface display in the screen according to the angle between the user and the screen, so that the user can use the electronic device conveniently.

Owner:HONG FU JIN PRECISION IND WUHAN CO LTD +1

Vision Protection Method and System Thereof

A vision protection method includes the steps of tracking at least one of eye activities of the viewer of the electronic device via a working condition detector; detecting possible eye conditions based on pupilary light reflex and responses; determining eye fatigue due to the eye activities of the viewer of the electronic device in a working mode of the electronic device; and generating a viewer eye result in response to the eye activities and possible eye conditions.

Owner:EYES4LIVES INC

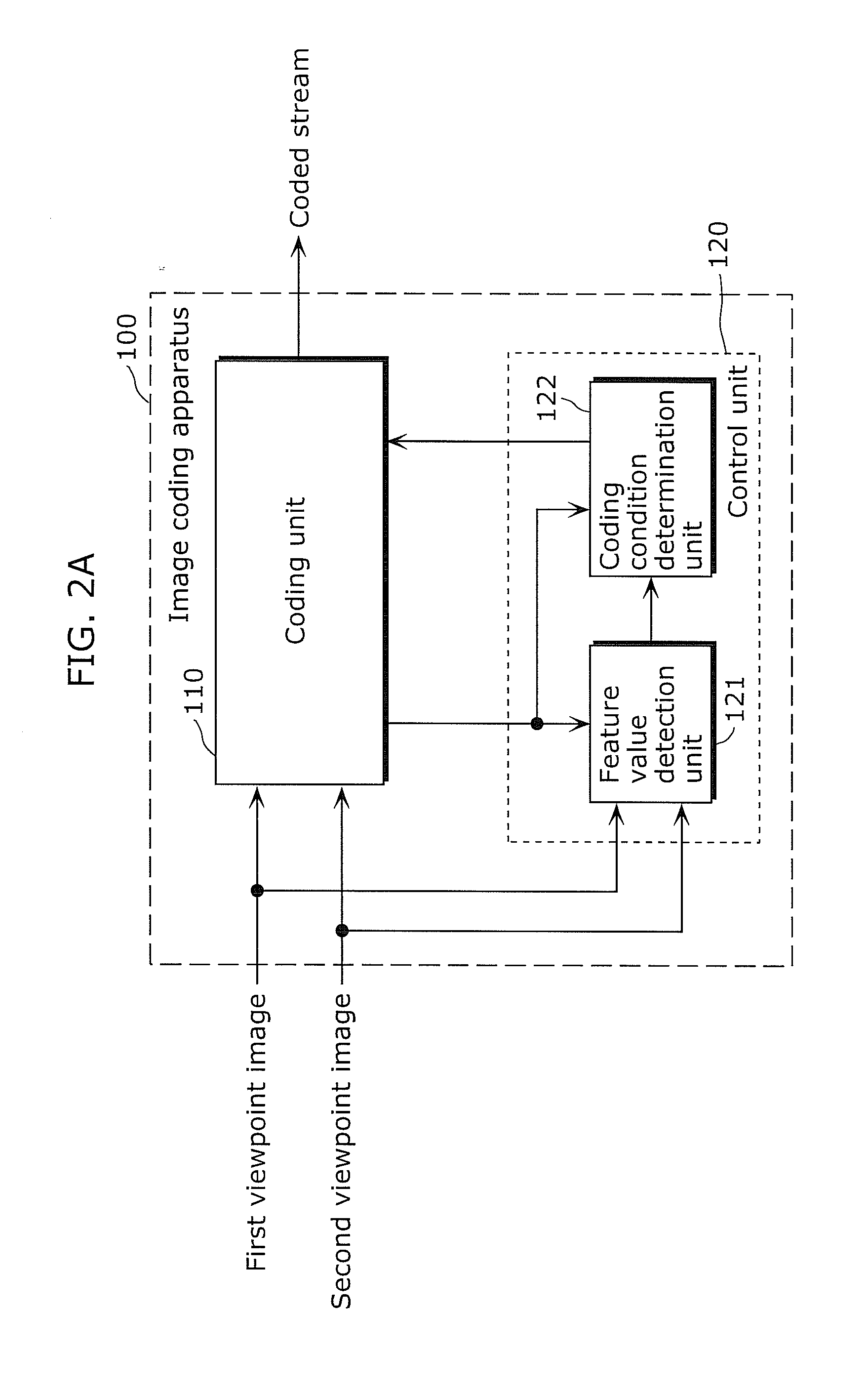

Image coding apparatus, image coding method, program, and integrated circuit

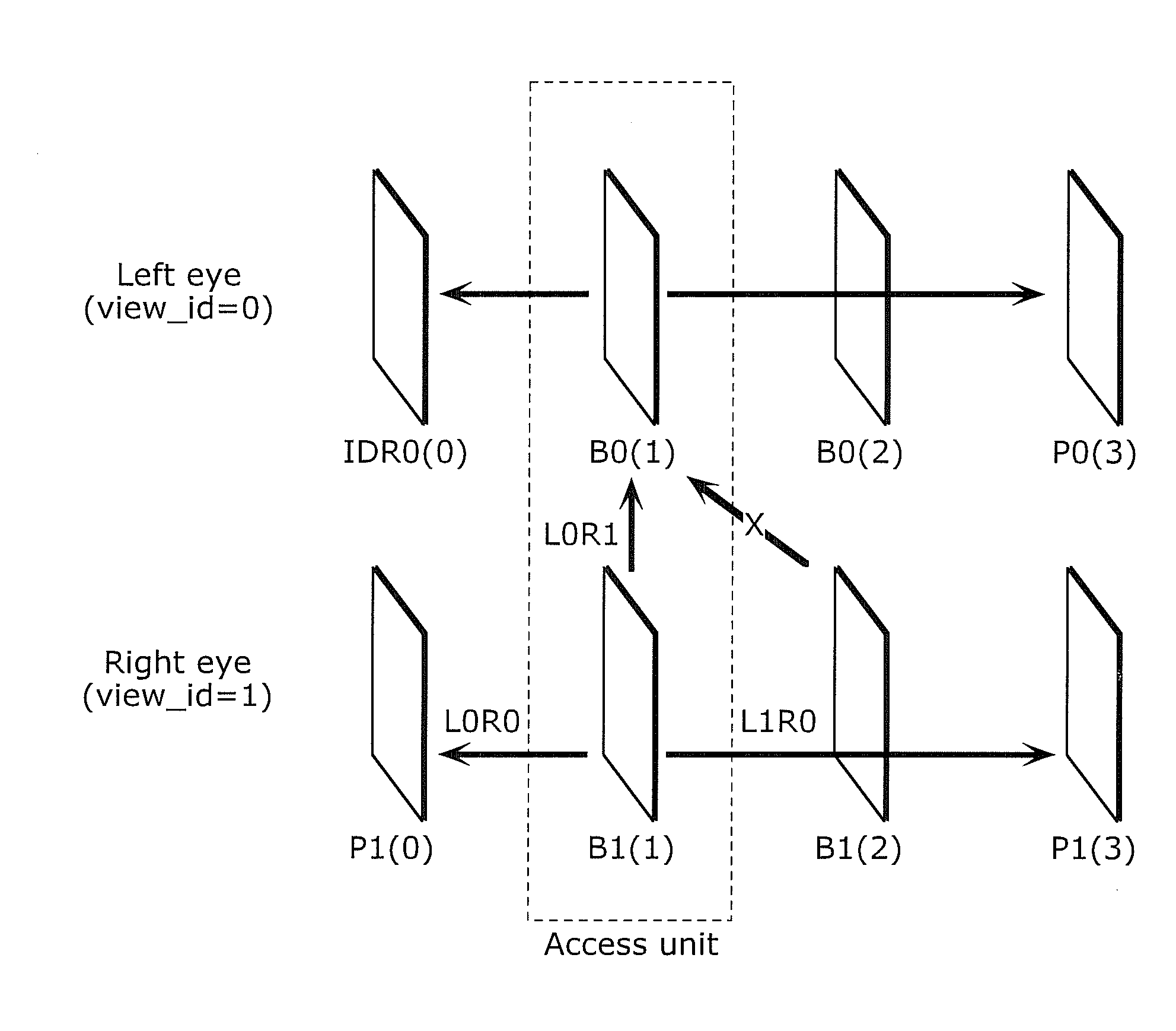

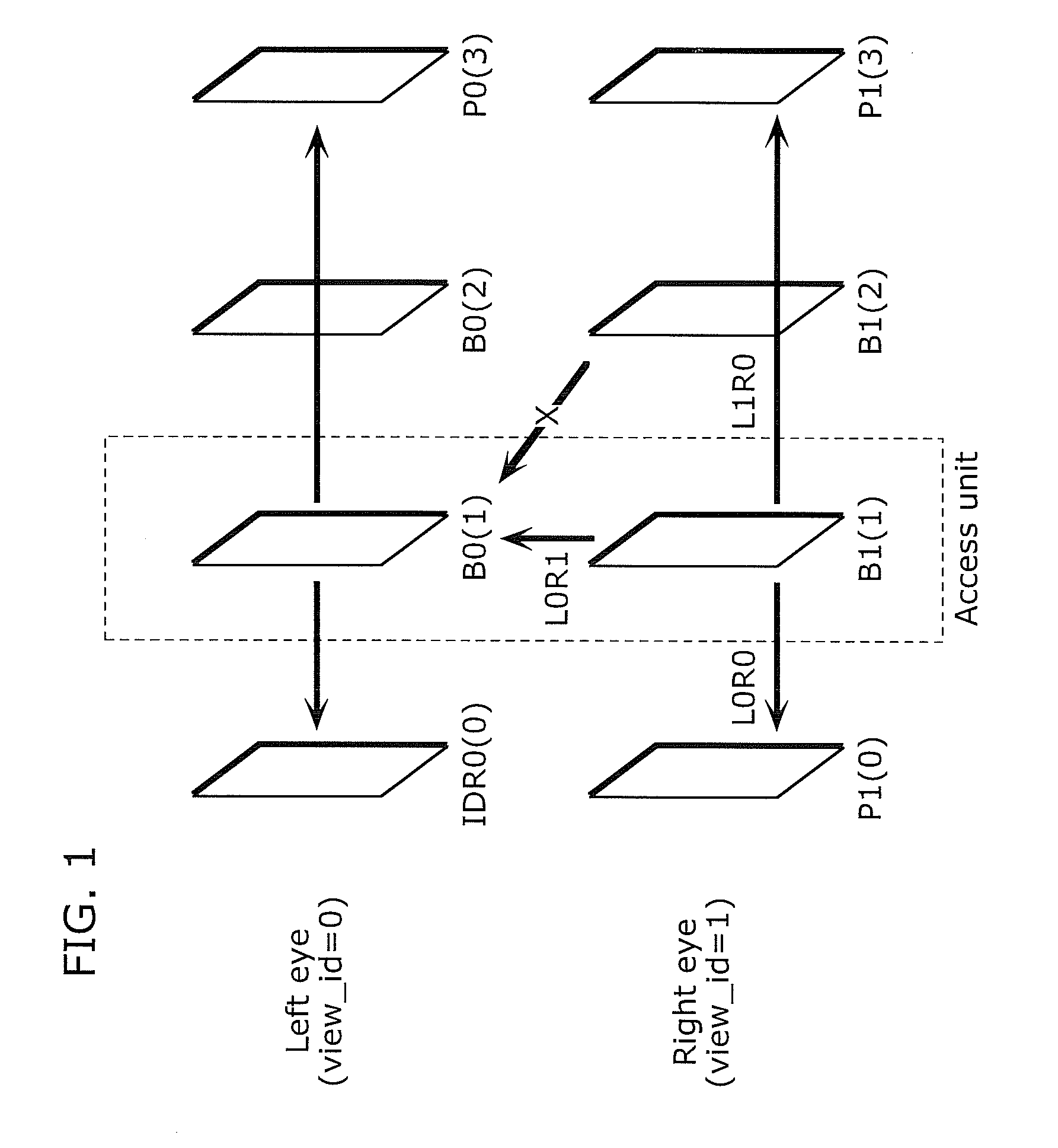

InactiveUS20120002022A1Avoid eye strainColor television detailsDigital video signal modificationStereoscopic videoComputer graphics (images)

An image coding apparatus records stereoscopic video partially as 2D video so as to enable display to be performed while seamlessly switching between 3D video and 2D video, and includes: a control unit that sets one of a 2D coding mode and a 3D coding mode which are modes of coding the stereoscopic video so that, when displayed in 3D, the stereoscopic video is displayed as 2D video and 3D video respectively; and a coding unit that, in the case where the control unit switches from the 3D coding mode to the 2D coding mode, codes the to stereoscopic video according to a 3D coding standard in the 3D coding mode, and codes the stereoscopic video according to the 3D coding standard using a coding condition in the 2D coding mode, the coding condition being a condition for causing the stereoscopic video to be viewed as the 2D video when displayed.

Owner:PANASONIC CORP

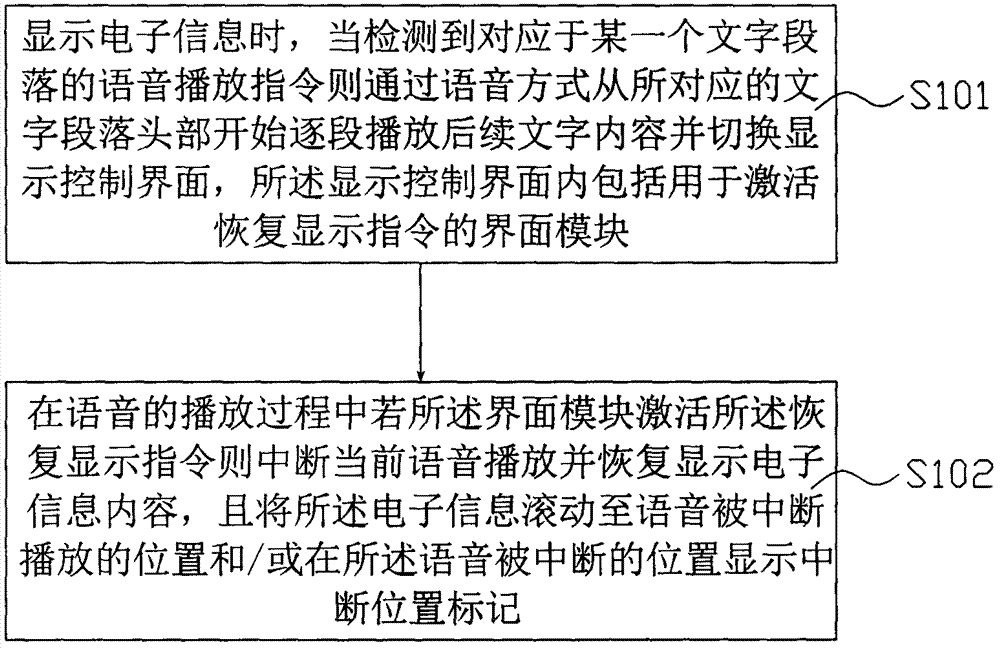

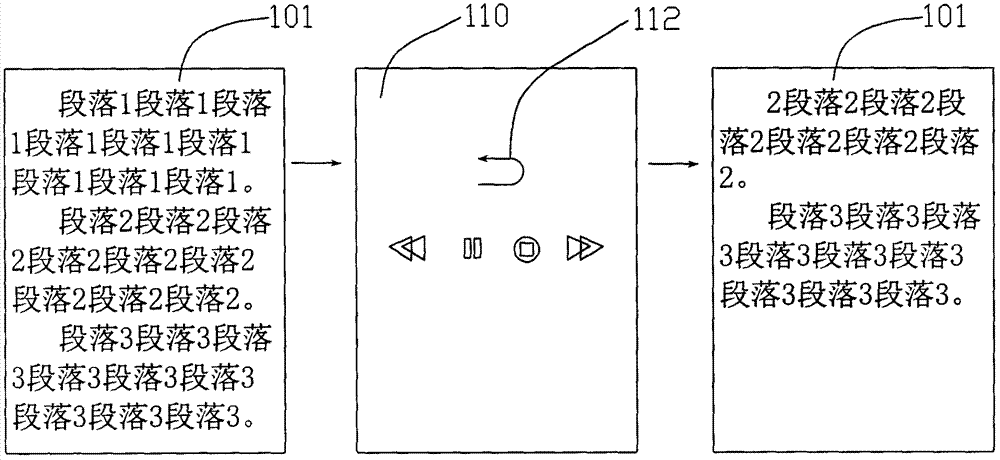

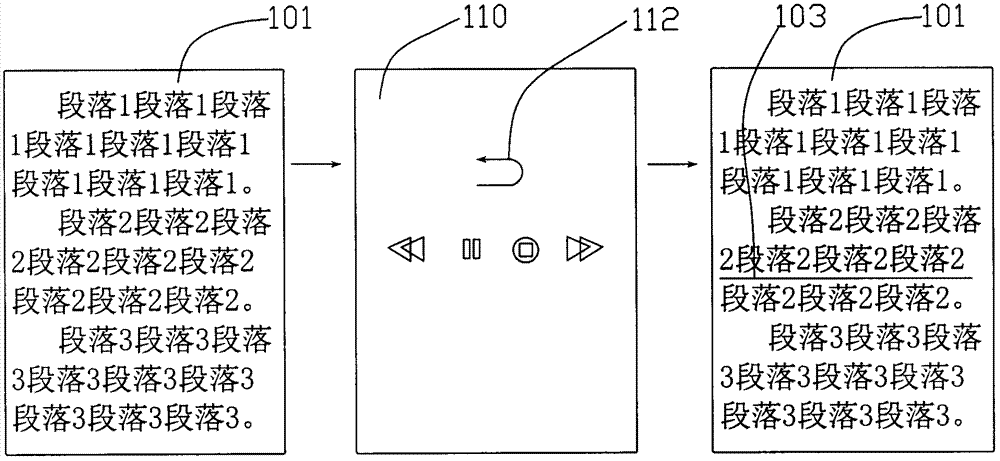

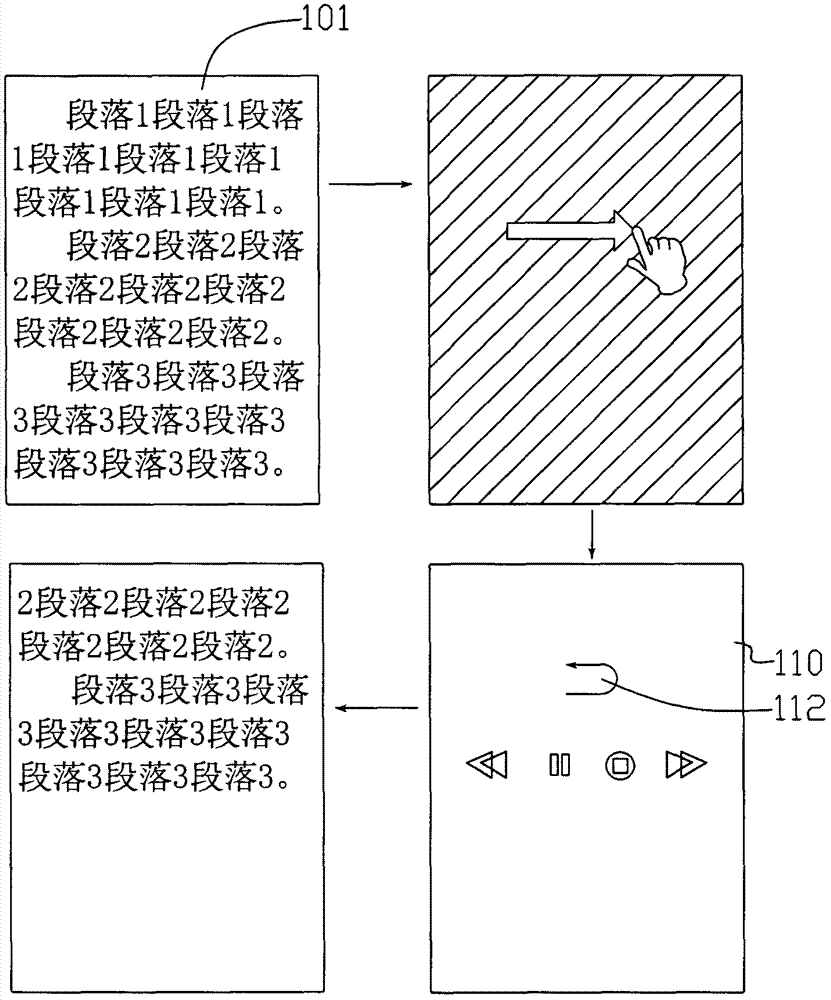

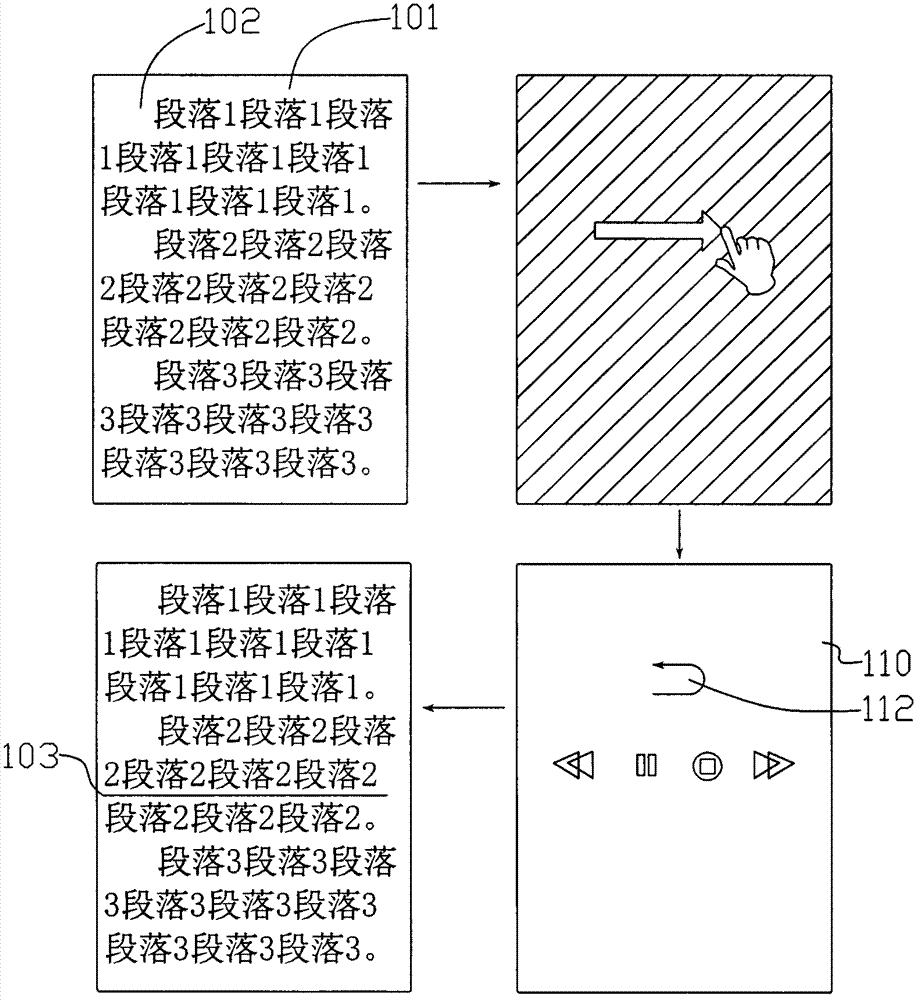

Handheld intelligent electronic equipment electronic information expressing method

InactiveCN104731476ASpend less time staring at screensAvoid eye strainSubstation equipmentInput/output processes for data processingComputer moduleElectronic information

The invention relates to a handheld intelligent electronic equipment electronic information expressing method which comprises the steps that during electronic information displaying, when a voice playing instruction corresponding to a certain character paragraph is detected, following character content is played paragraph by paragraph in a voice mode from the head of the corresponding character paragraph, a control interface is displayed in a switching mode, and an interface module for activating a recovering displaying instruction is included in the control interface; and during a voice playing process, if the interface module activates the recovering displaying instruction, current voice playing is interrupted, electronic information content is displayed in a recovering mode, electronic information rolls to the position where voice playing is interrupted, and / or an interrupting position mark is displayed at the position where voice is interrupted. When electronic information is displayed through the method, a user can carry out switching between the two modes of voice listening and character reading, accordingly, the time of the user who stares at a screen during electronic information looking up is effectively shortened, and eye fatigue is avoided.

Owner:SUZHOU LEJUYITANG ELECTRONICS SCI & TECH CO LTD

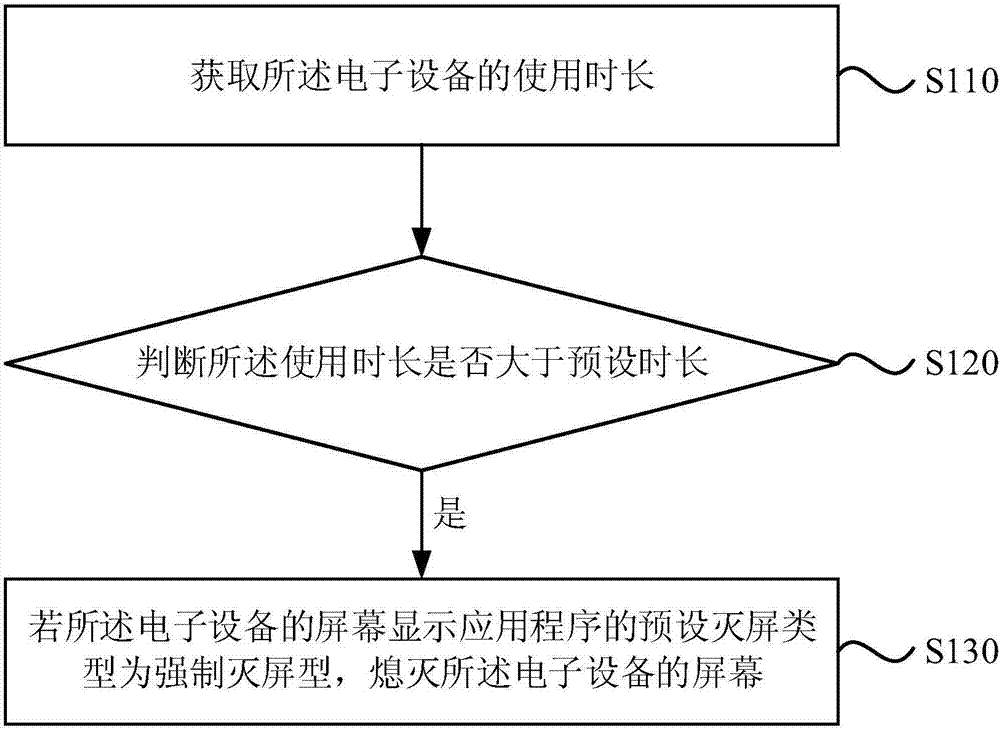

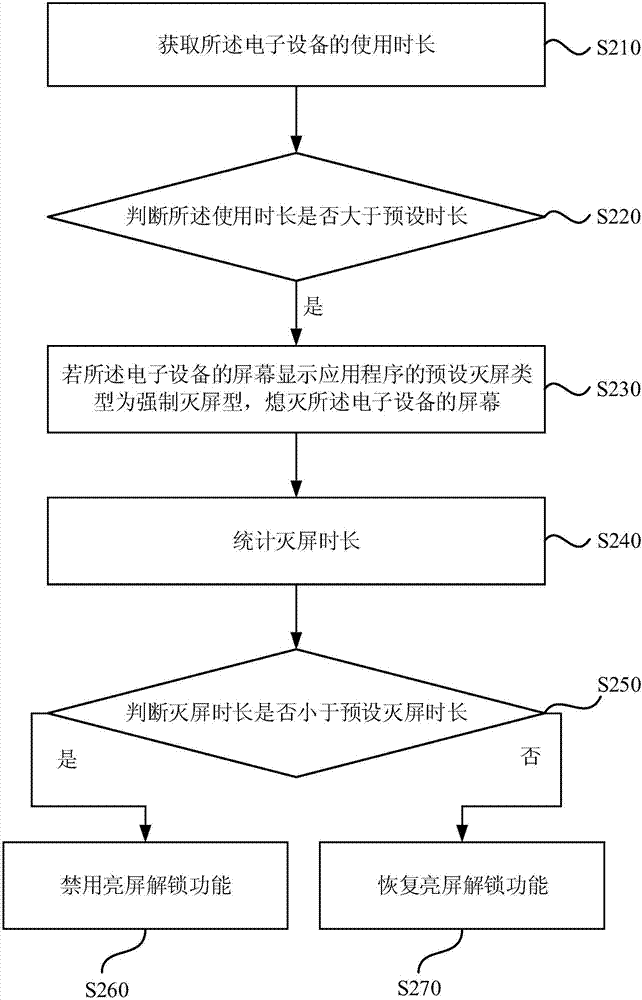

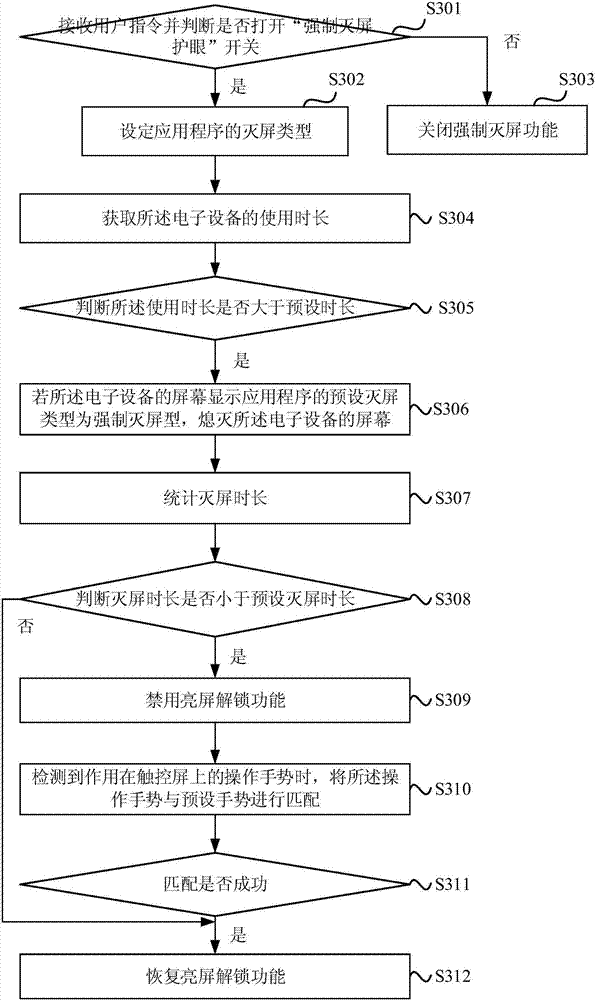

Eye protection method and device of electronic device

InactiveCN106873894AAvoid eye strainInput/output processes for data processingProtecting eyeComputer science

The embodiment of the invention discloses an eye protection method and device of an electronic device. An application is installed in the electronic device. The method includes the steps that the use duration of the electronic device is obtained; whether the use duration is longer than a preset duration or not is judged; when the use duration is longer than the preset duration, a screen of the electronic device is put out if the screen of the electronic device displays that a preset screen put-out type of the application is a forcing screen put-out type. The eye protection method and device of the electronic device prevent the situation that eye fatigue and other eye diseases are caused when a user uses the electronic device for a long time, and accordingly the aim of protecting eyes is achieved.

Owner:SHANGHAI YUDE INFORMATION TECH CO LTD

Eye medicine for preventing and treating asthenopia and allergy

InactiveCN1839834AOvercome the disadvantages of taking single medicineCompatibility is reasonableSenses disorderAnhydride/acid/halide active ingredientsMentholAllergy

Disclosed is a compound preparation for treating and preventing eye strain and allergy, which comprises (by weight percent) taurine 0.1-99.9%, naphazoline hydrochloride 0.01-99.9%, vitamin B6 0.01-99.9%, chlorpheniramine maleate 0.01-99.9%, and right amount of auxiliary therapeutic medicaments such as menthol, sodium hyaluronate, glycerine and medicinal findings such as preservative agent and buffering agent.

Owner:崔彬

Vision Protection Method and System Thereof

The vision protection method and system thereof is provided to ensure a viewer to rest his / her eyes after viewing on an electronic device for a certain period, wherein the eyesight protection method includes the steps of initially counting down a predetermined working time of a working mode, switching the working mode to a resting mode to temporarily halt the current working mode of the electronic device, and resuming the operation of the working mode that the viewer was previously working on. In that manner, the viewer is enforced to rest his / her eyes after every certain period.

Owner:EYES4LIVES INC

Handheld intelligent electronic equipment information expressing method

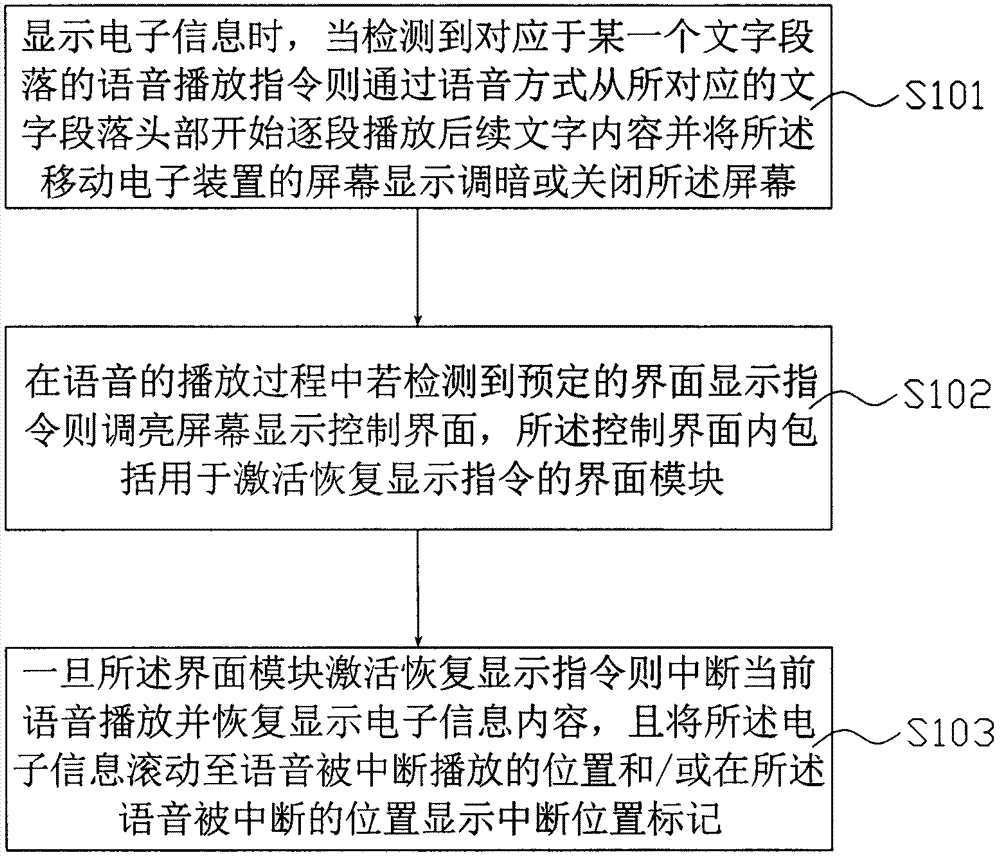

InactiveCN104731327ASpend less time staring at screensAvoid eye strainInput/output for user-computer interactionGraph readingElectronic informationHuman–computer interaction

The invention relates to a handheld intelligent electronic equipment information expressing method which comprises the steps that during electronic information displaying, when a voice playing instruction corresponding to a certain character paragraph is detected, following character content is played paragraph by paragraph in a voice mode from the head of the corresponding character paragraph, screen displaying of a mobile electronic device is adjusted to be dark, or a screen is turned off; during a voice playing process, if a preset interface displaying instruction is detected, the screen is adjusted to be bright, a control interface is displayed, and an interface module for activating a recovering displaying instruction is included in the control interface; and once the interface module activates the recovering displaying instruction, current voice playing is interrupted, electronic information content is displayed in a recovering mode, electronic information rolls to the position where voice playing is interrupted, and / or an interrupting position mark is displayed at the position where voice is interrupted. When electronic information is displayed through the method, the time of a user who stares at a screen is effectively shortened, and eye fatigue is avoided.

Owner:SUZHOU LEJUYITANG ELECTRONICS SCI & TECH CO LTD

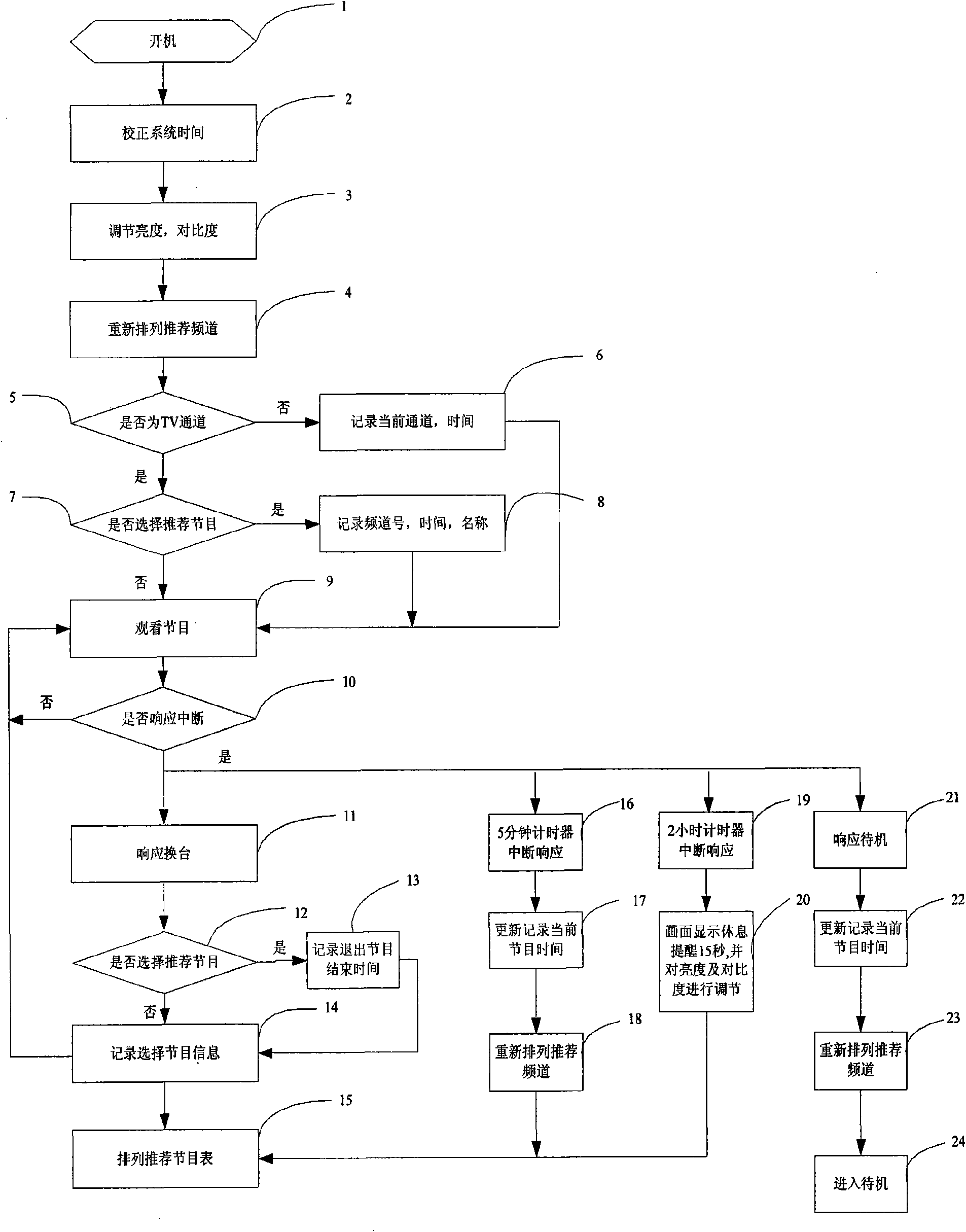

Television time management method

InactiveCN101567986AProtect eyesightAvoid eye strainTelevision system detailsColor television detailsSystem timeTime information

The invention discloses a television time management method, comprising: adjusting the system time of the current television based on the time information in the television program information; adjusting the brightness and contrast based on the system time of the television. The television time management method automatically adjusts the brightness and contrast of the television based on the time when the consumer watches the television, in order to accommodate the day and night environment brightness and the consumer eyesight can be effectively protected.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

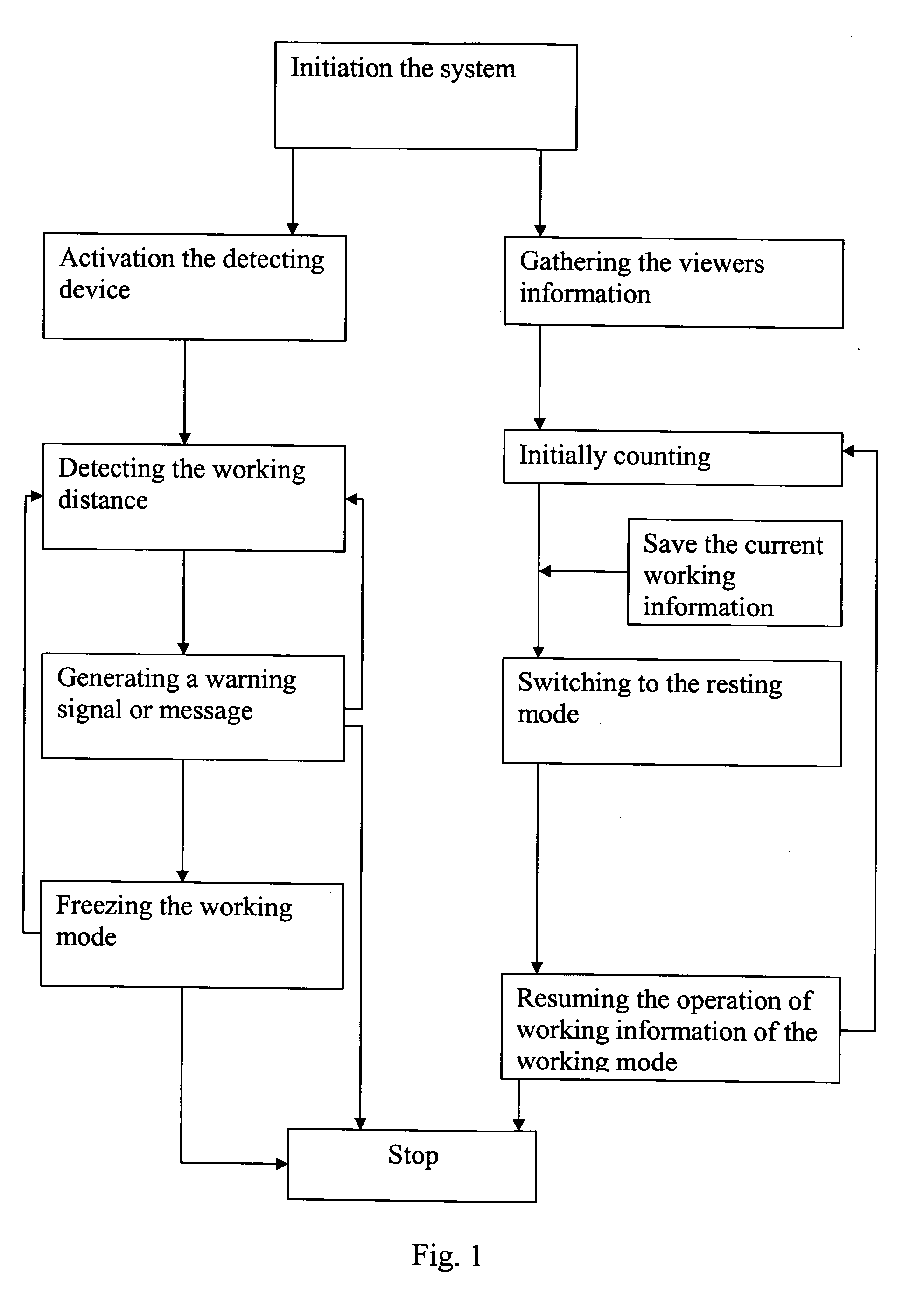

Vision protection method and system thereof

The vision protection method and system thereof is provided to ensure a viewer to rest his / her eyes after viewing on an electronic device for a certain period, wherein the eyesight protection method includes the steps of detecting one of more working parameters of the viewer in responsive to a preset working threshold in a working mode of the electronic device during the viewer is working on a current work displaying by the electronic device; switching the working mode of the electronic device to a resting mode; and switching the electronic device from the resting mode back to the working mode to resume the display of the current work of the electronic device. Therefore, the viewer is enforced to rest his / her eyes after every certain period.

Owner:EYES4LIVES INC

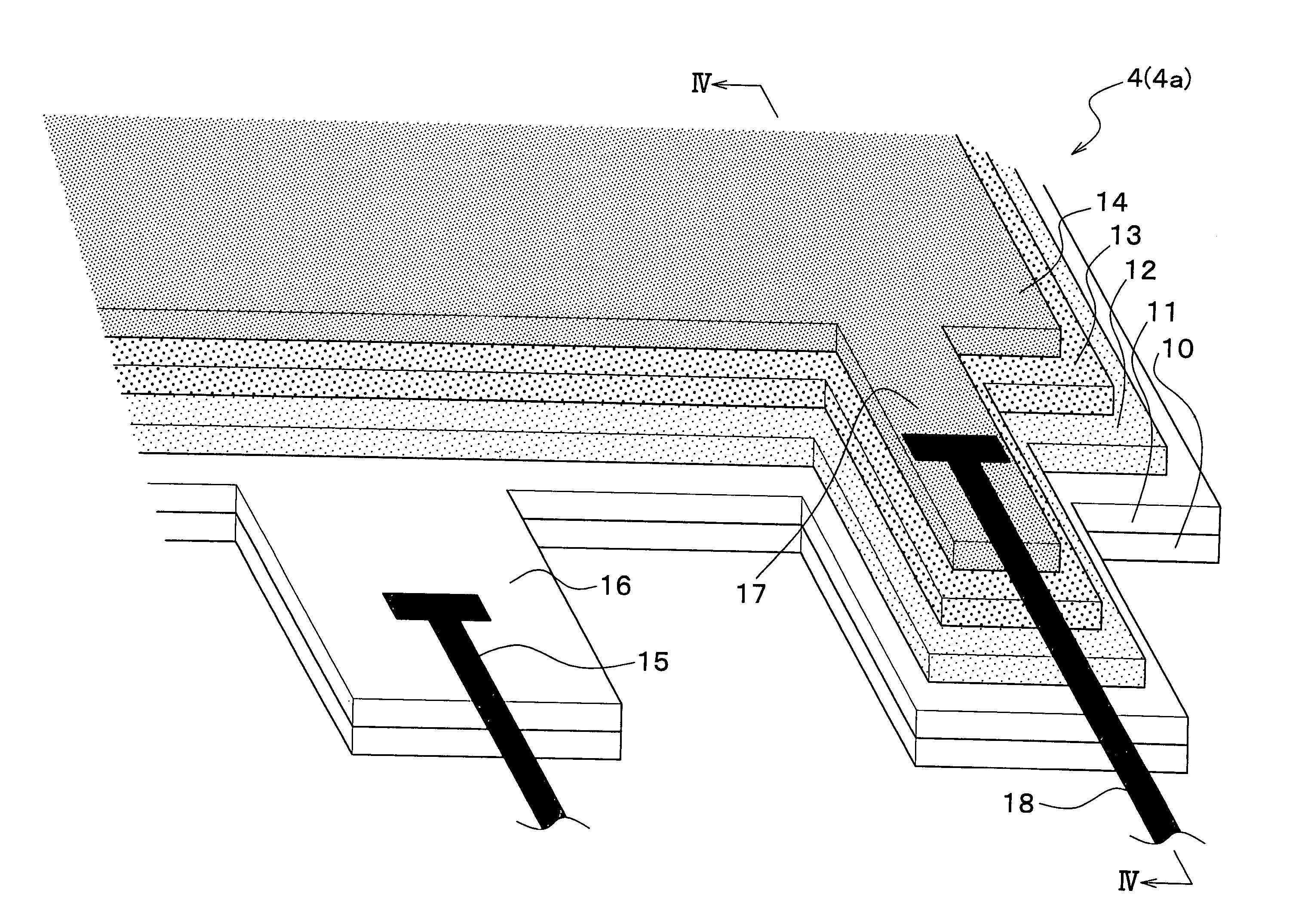

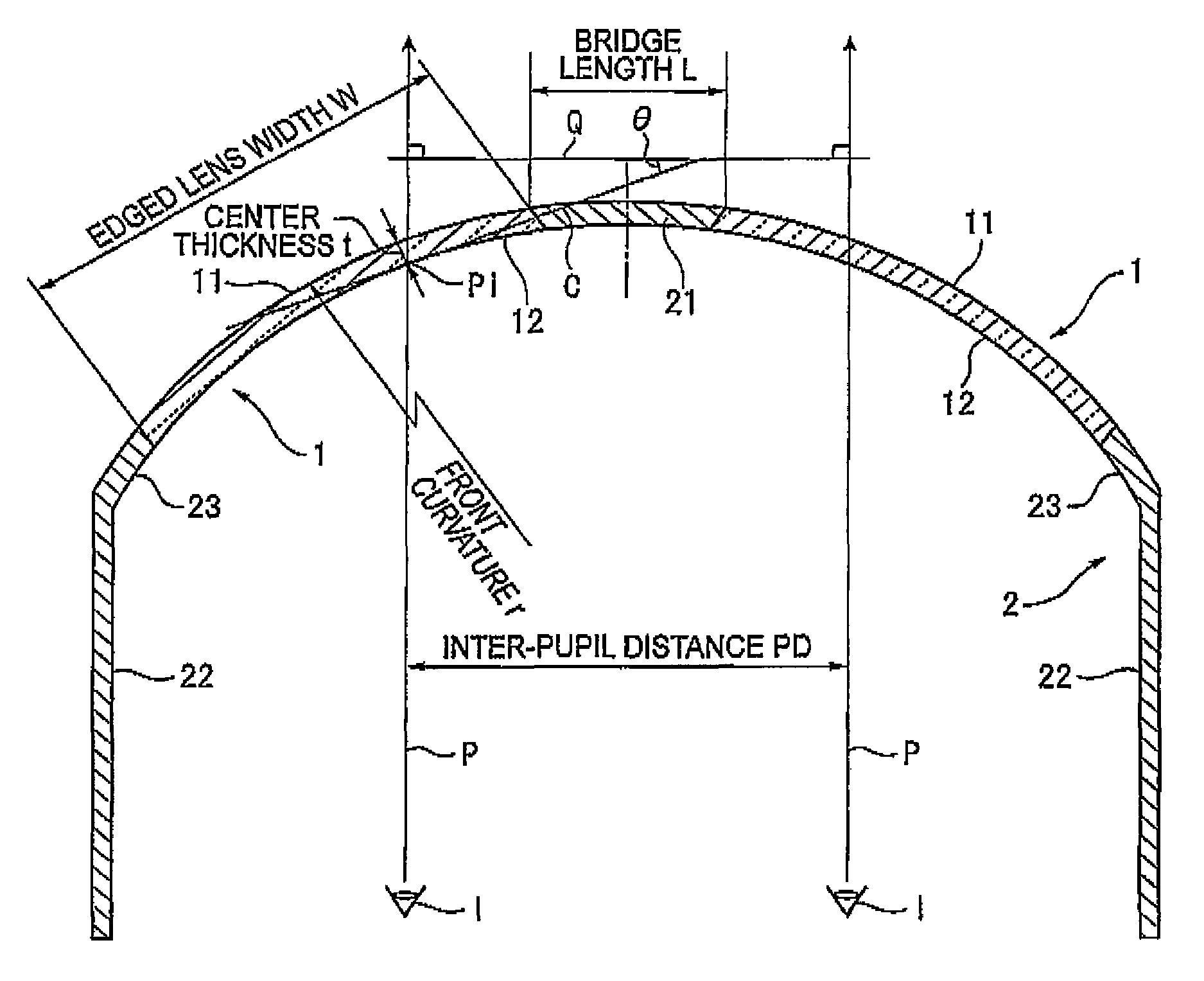

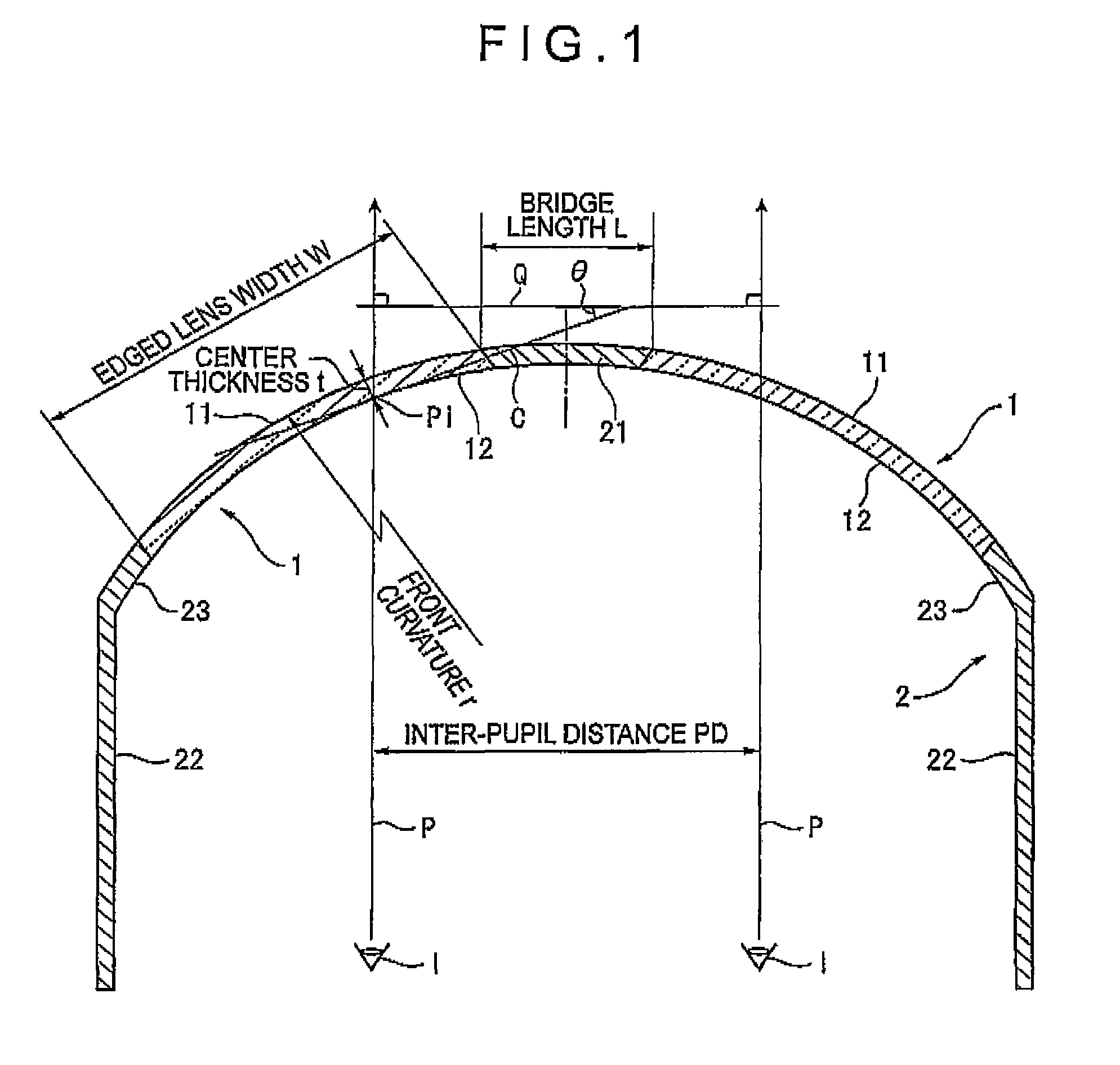

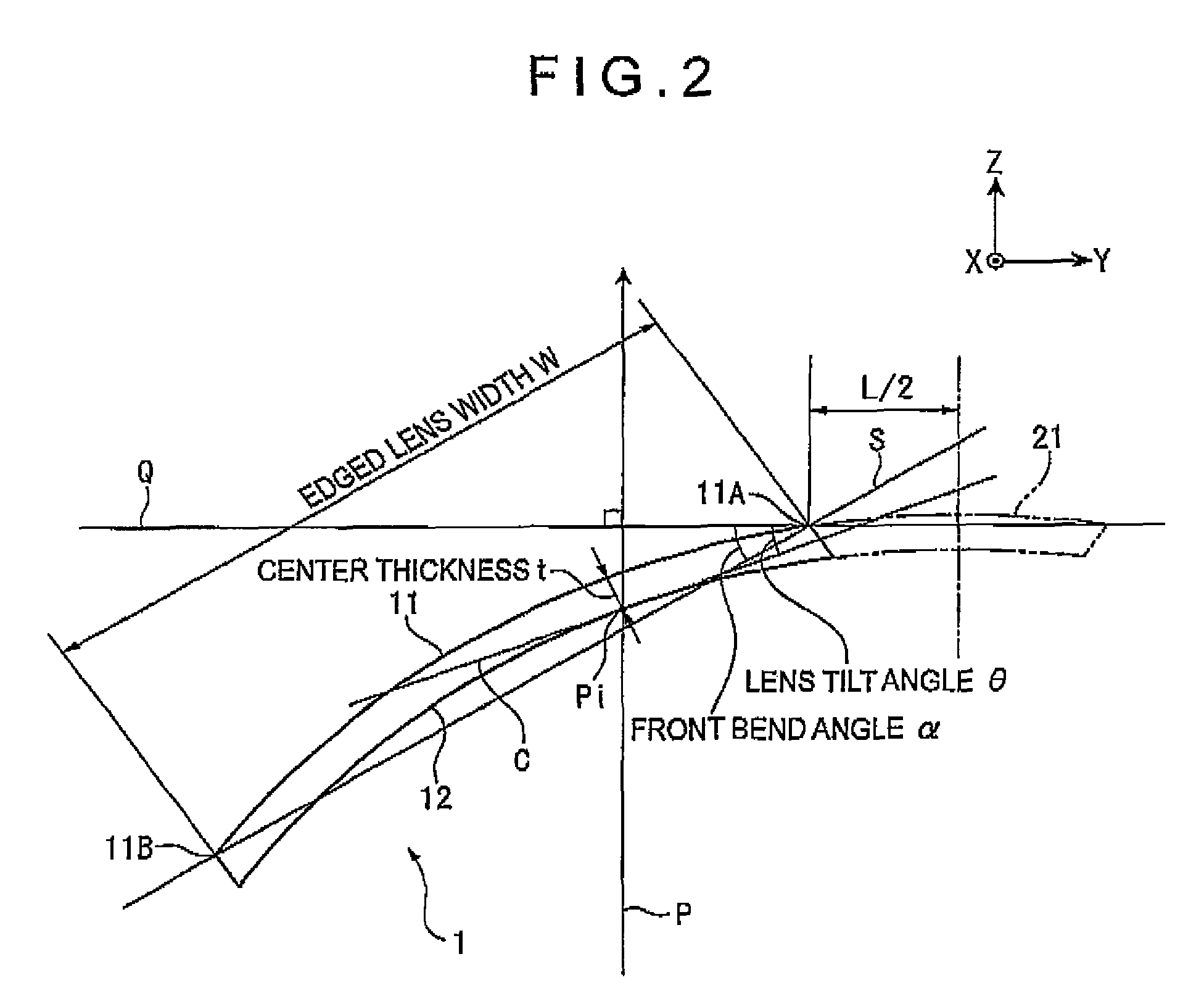

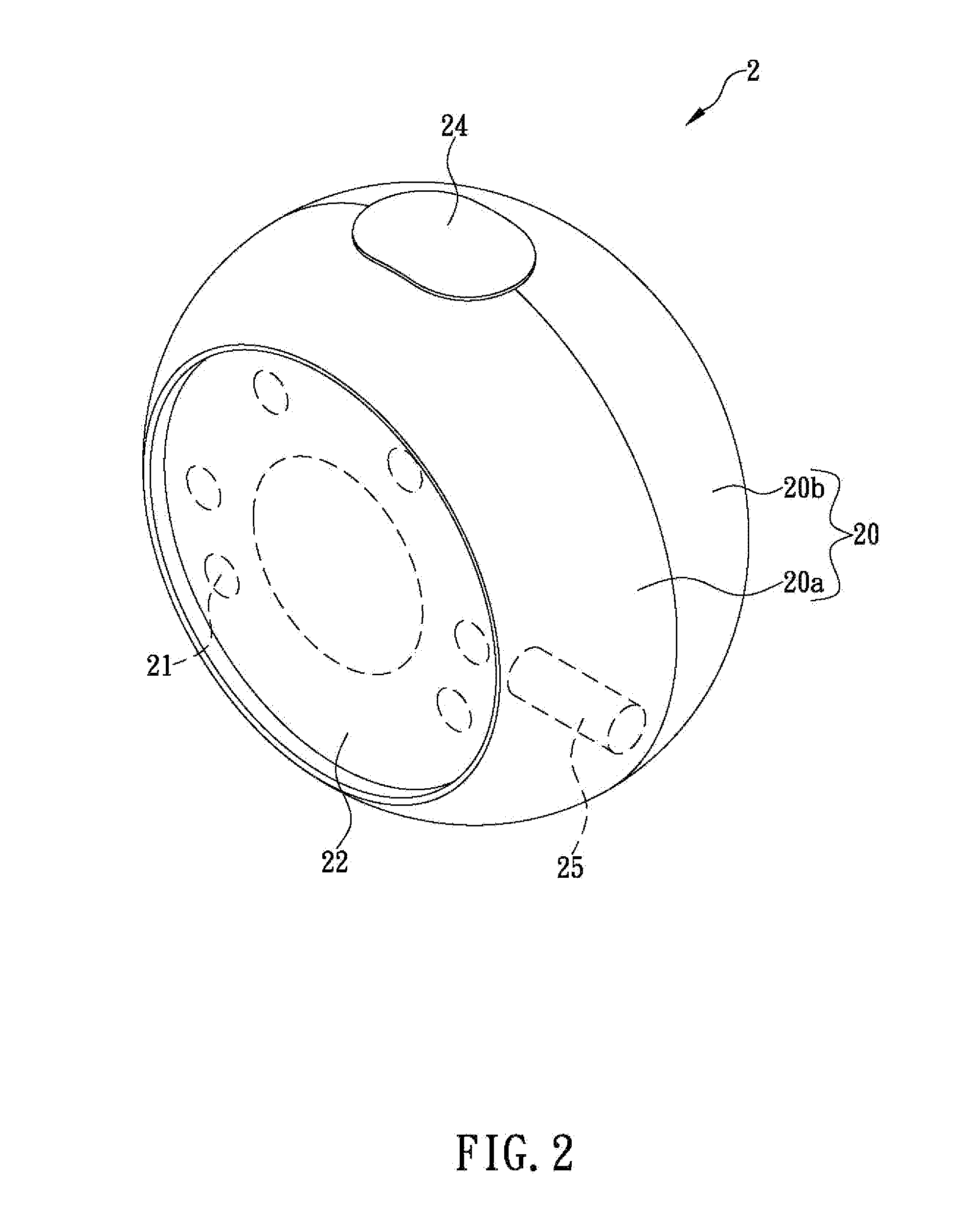

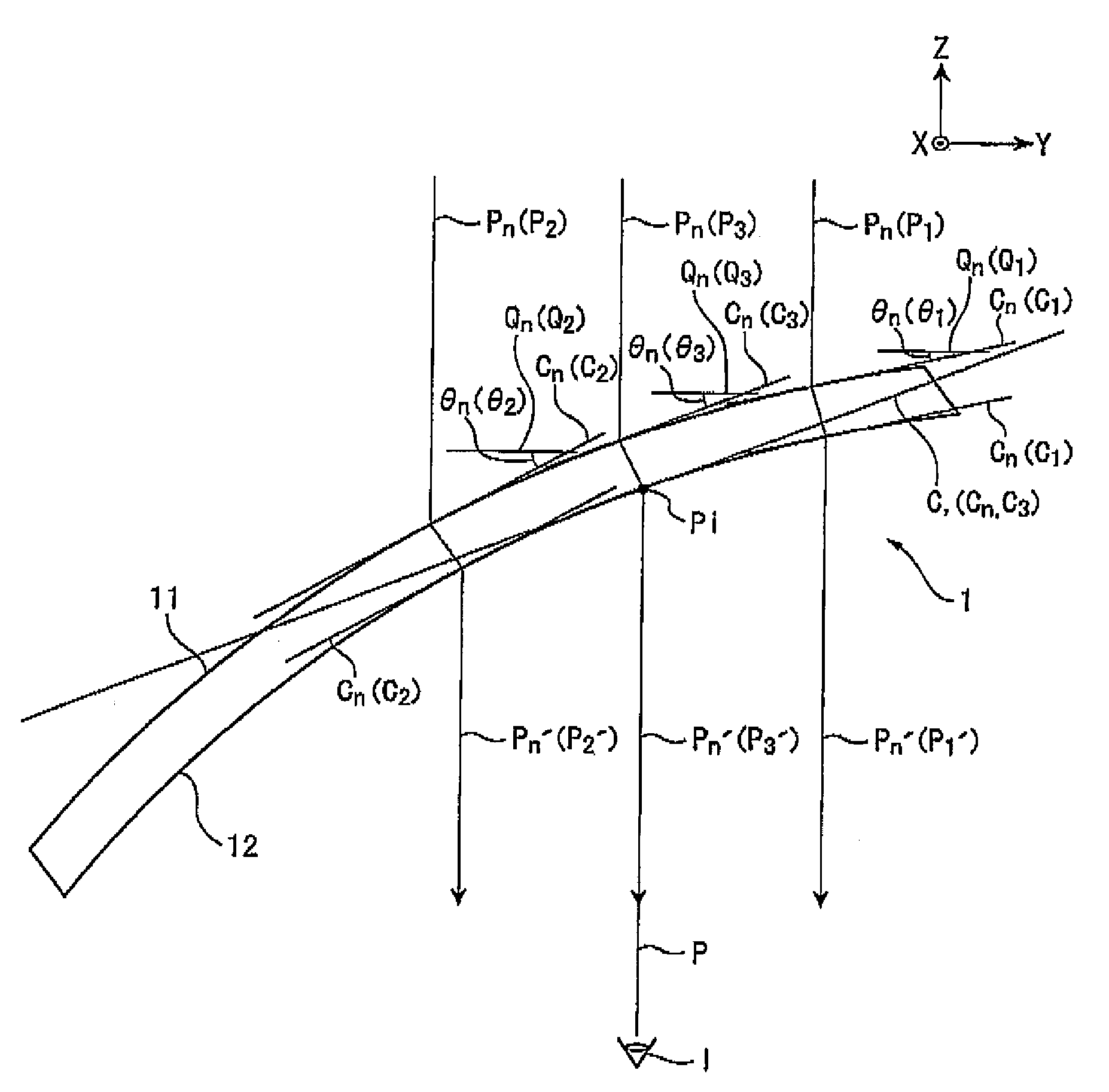

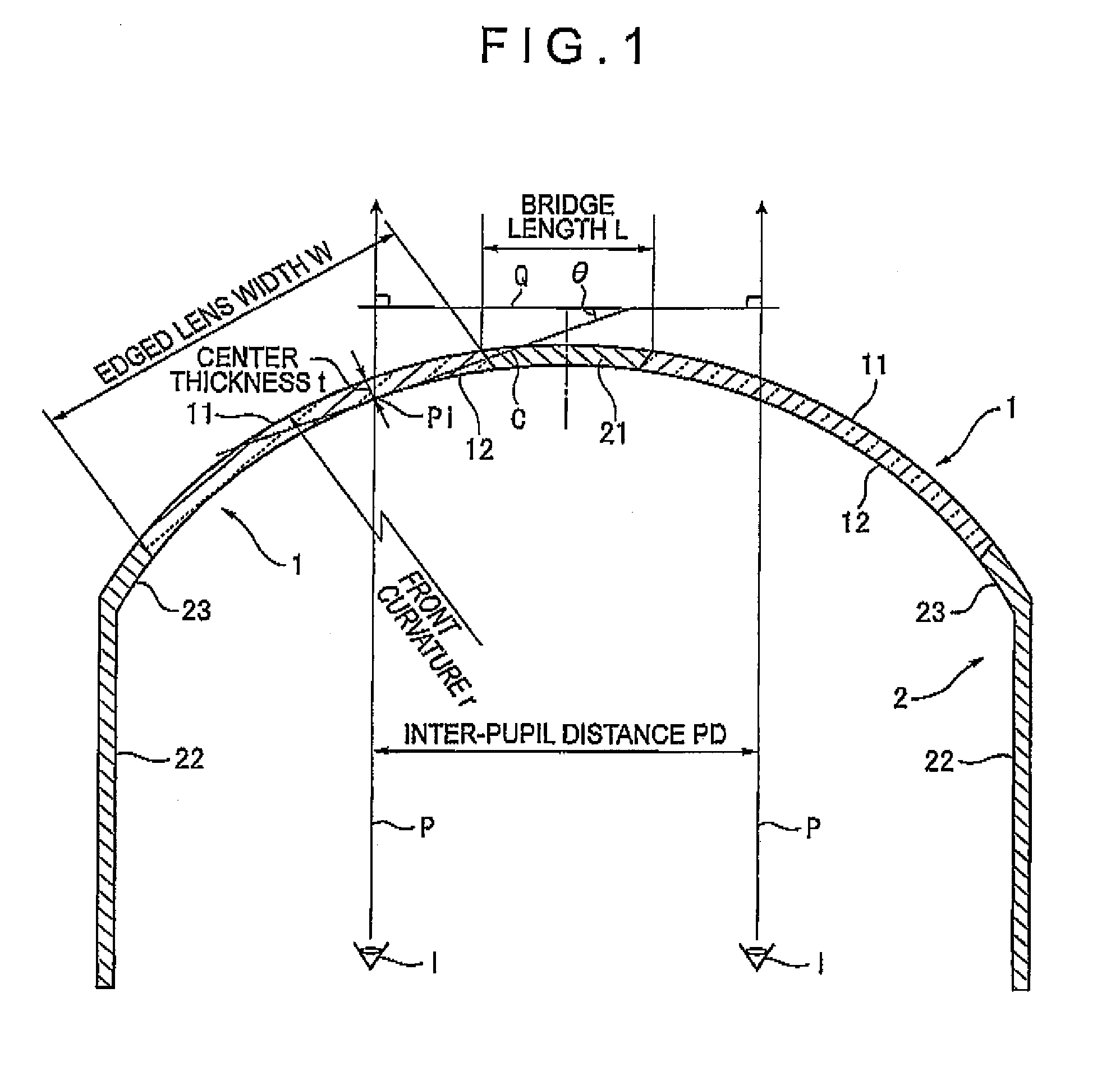

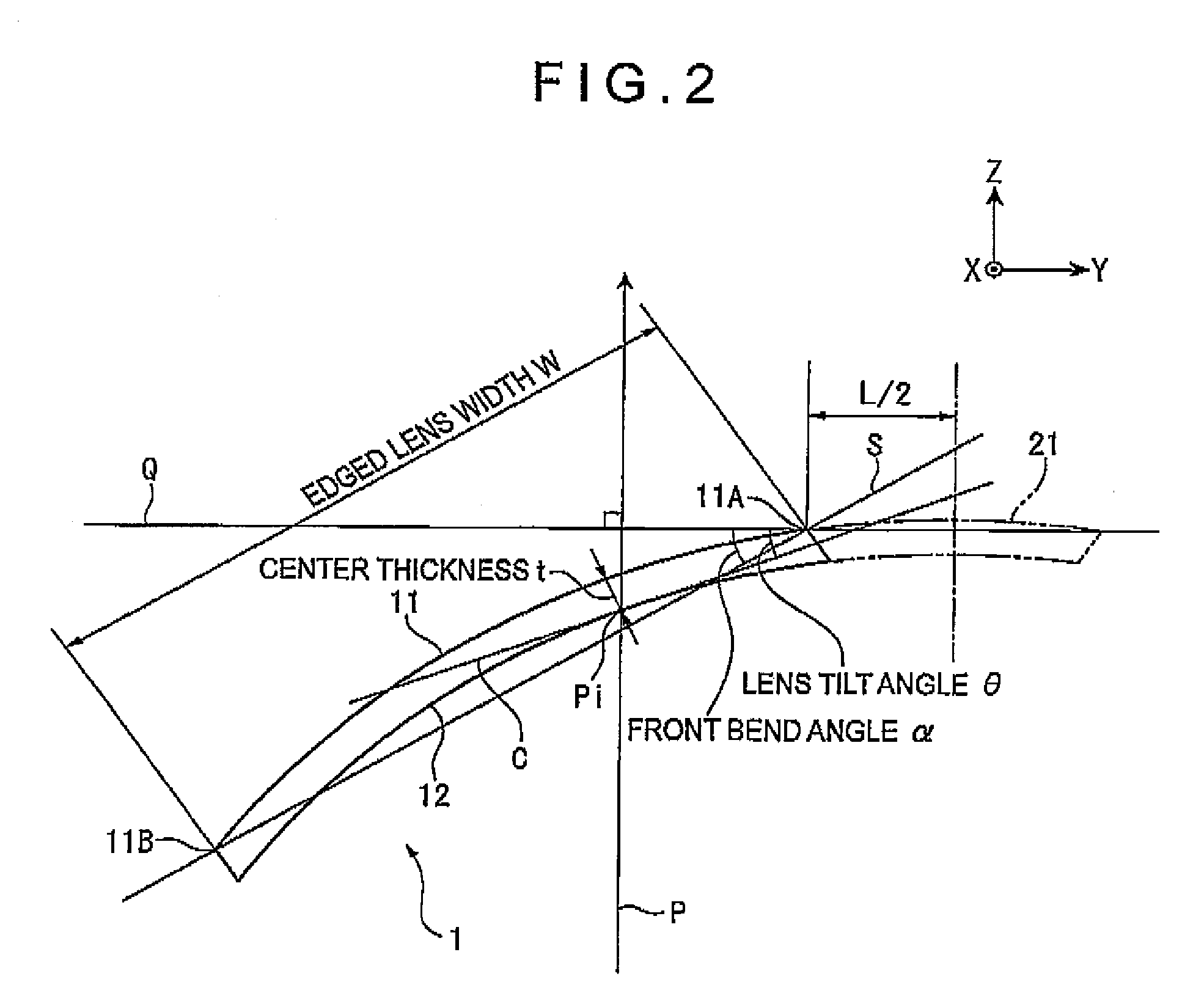

Method for designing spectacle lens, and spectacles

ActiveUS7717559B2Avoid eye strainPrevent surfaceSpectales/gogglesEye diagnosticsUses eyeglassesEyeglass lenses

A method for designing a spectacle lens that includes an optical convex surface on an object side of the spectacle lens and an optical concave surface on an eye side of the spectacle lens and is mounted in a spectacle frame in a manner tilting with respect to a forward sight line, the optical convex surface being spherical, the optical concave surface being optically curved according to a prescription, the method including: defining a design reference point at an intersection of the optical concave surface and the forward sight line; and determining an angle formed by a tangent line at the design reference point and a perpendicular plane perpendicular to the forward sight line as a lens tilt angle θ with which the spectacle lens is mounted in the spectacle frame.

Owner:HOYA LENS MFG PHILIPPINES

Vision protection method and system thereof

ActiveUS8884735B2Avoid eye strainIndoor gamesElectric testing/monitoringComputer scienceVisual acuity

The vision protection method and system thereof is provided to ensure a viewer to rest his / her eyes after viewing on an electronic device for a certain period, wherein the eyesight protection method includes the steps of detecting one of more working parameters of the viewer in responsive to a preset working threshold in a working mode of the electronic device during the viewer is working on a current work displaying by the electronic device; switching the working mode of the electronic device to a resting mode; and switching the electronic device from the resting mode back to the working mode to resume the display of the current work of the electronic device. Therefore, the viewer is enforced to rest his / her eyes after every certain period.

Owner:EYES4LIVES INC

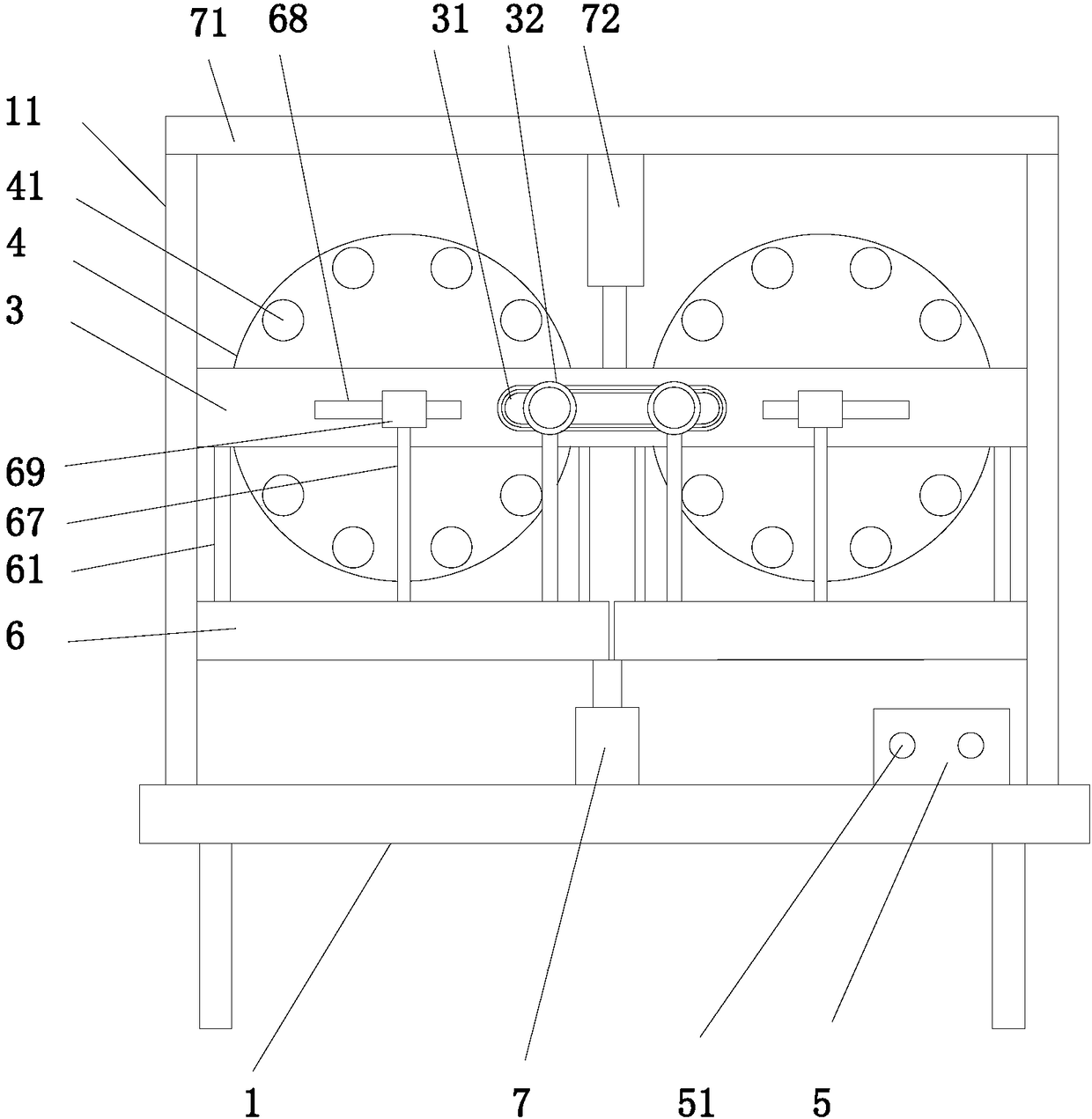

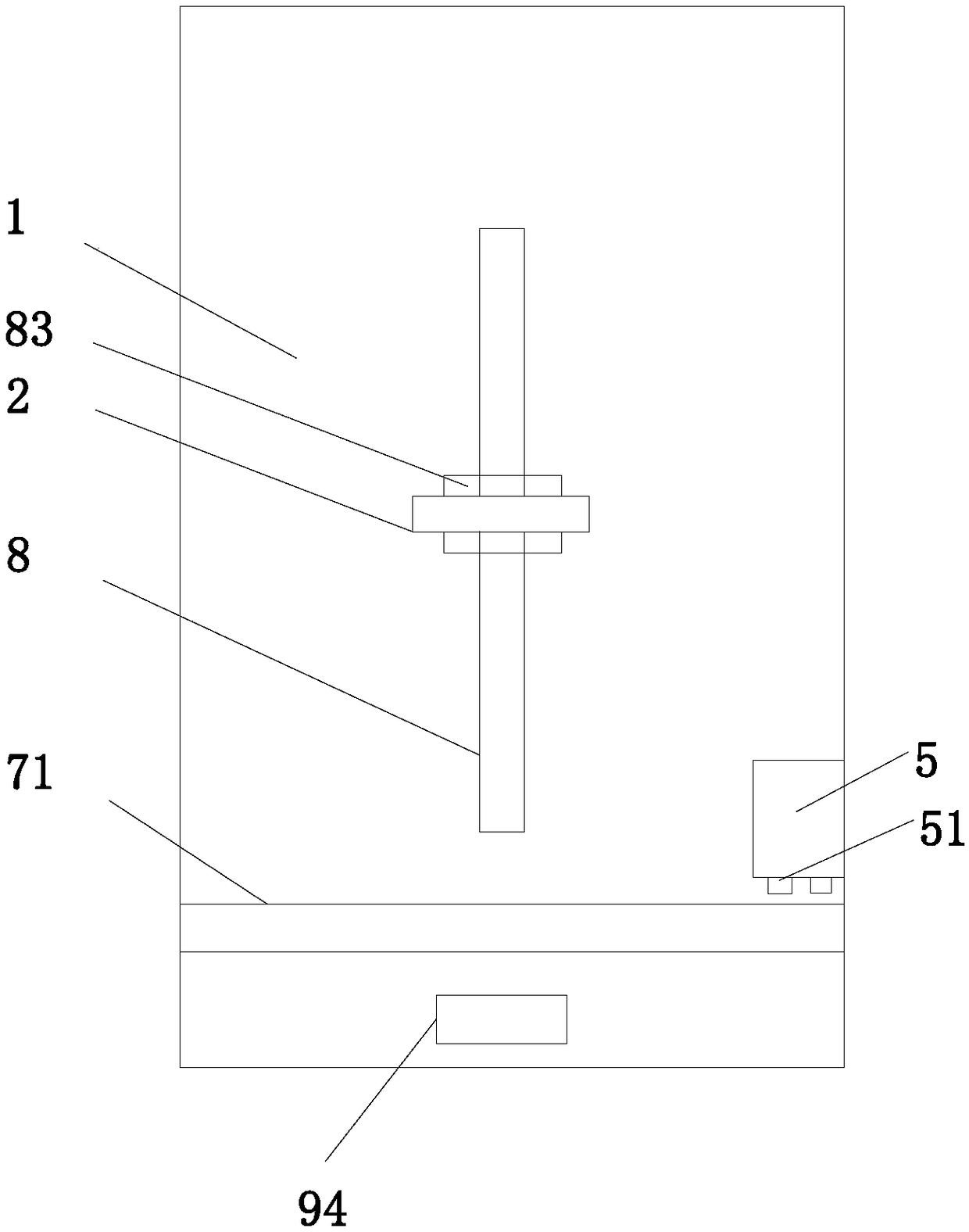

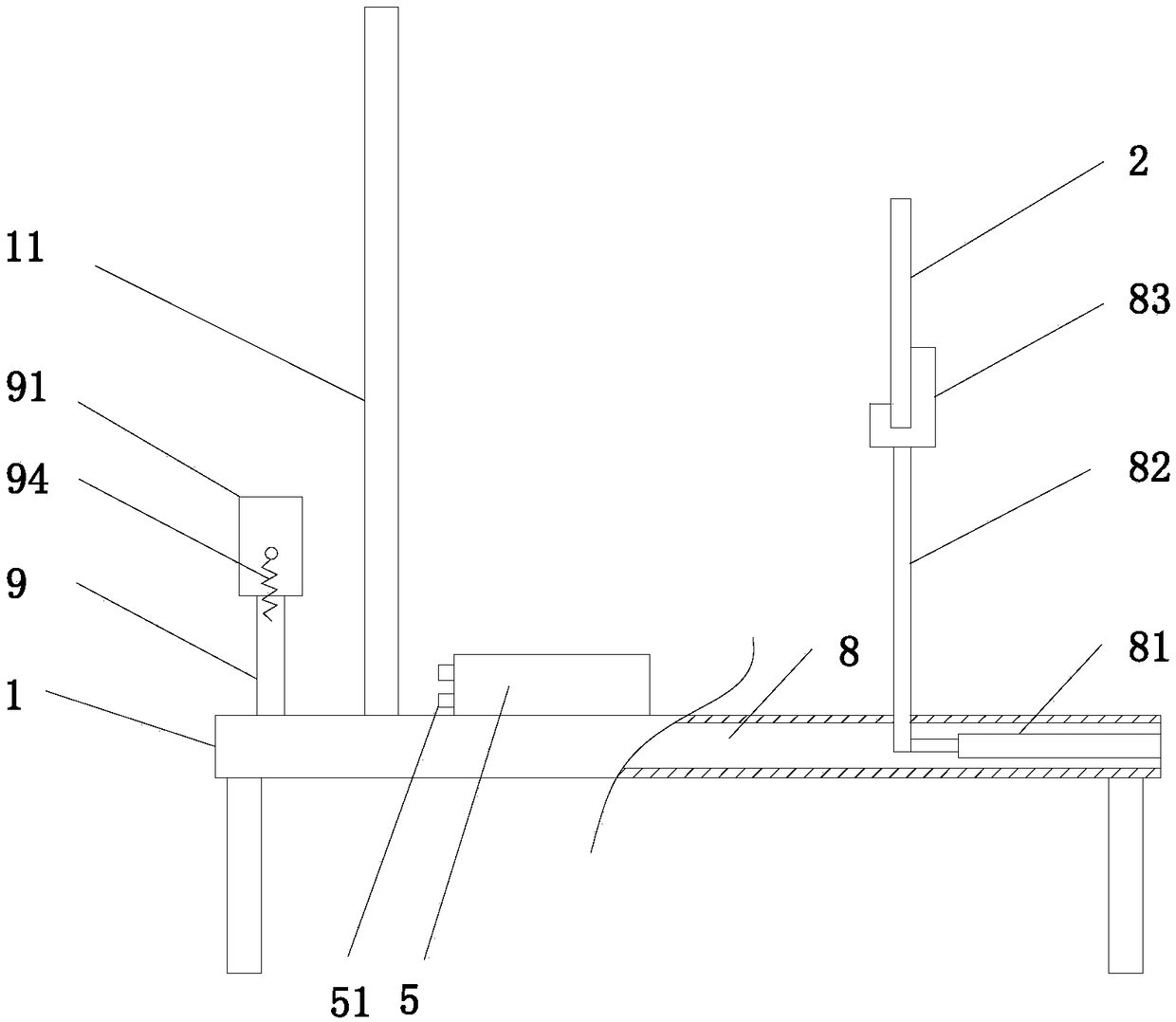

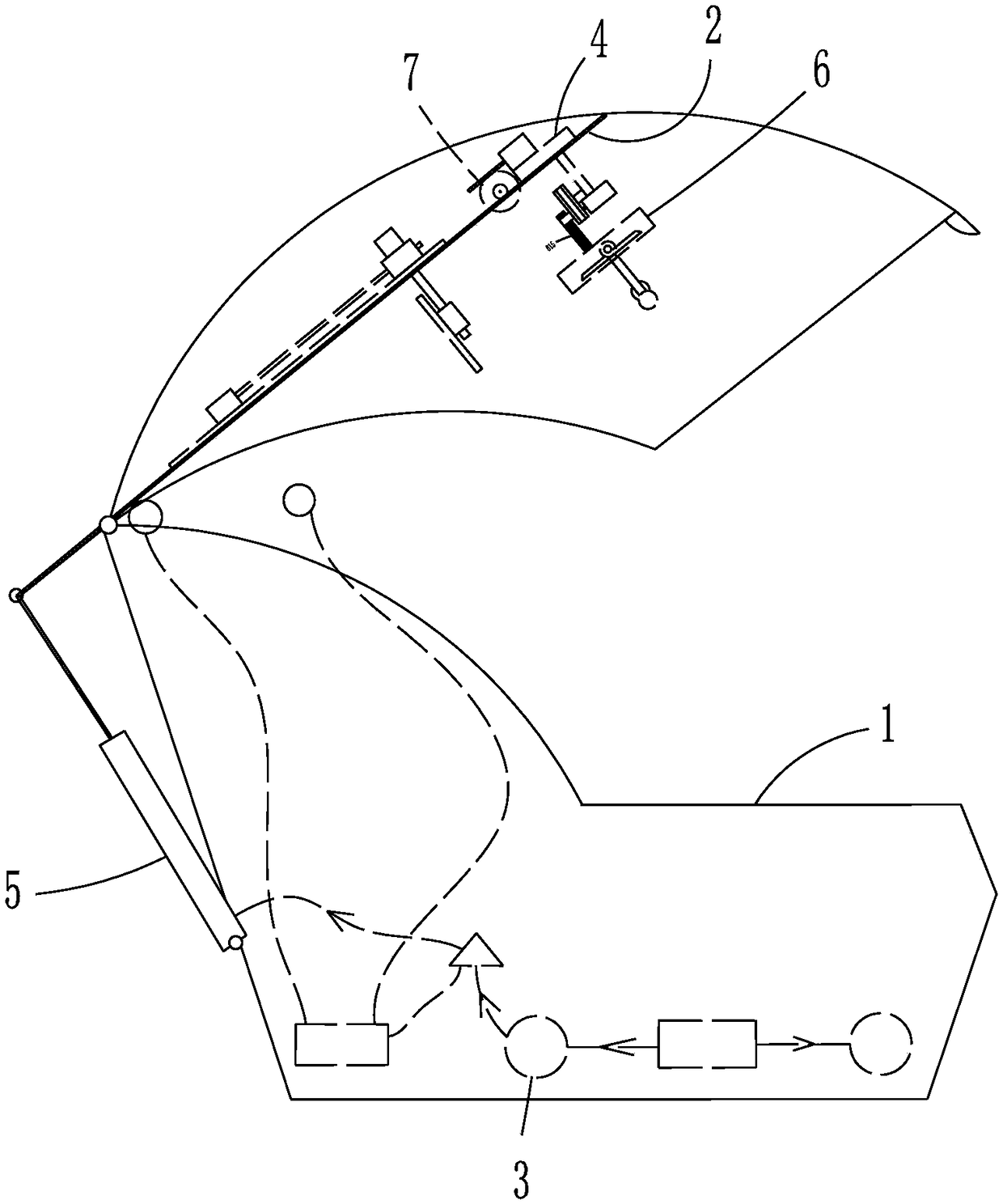

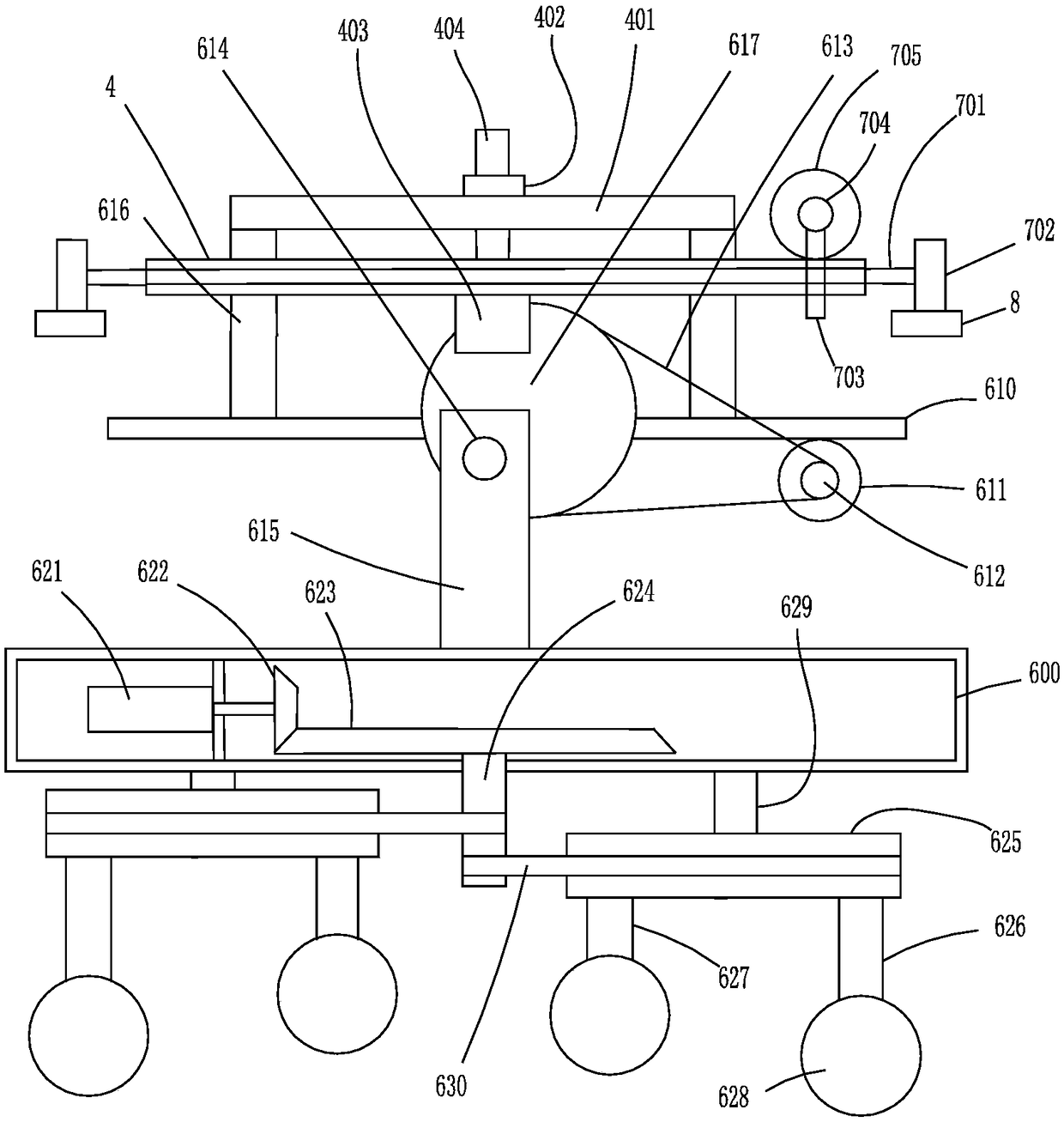

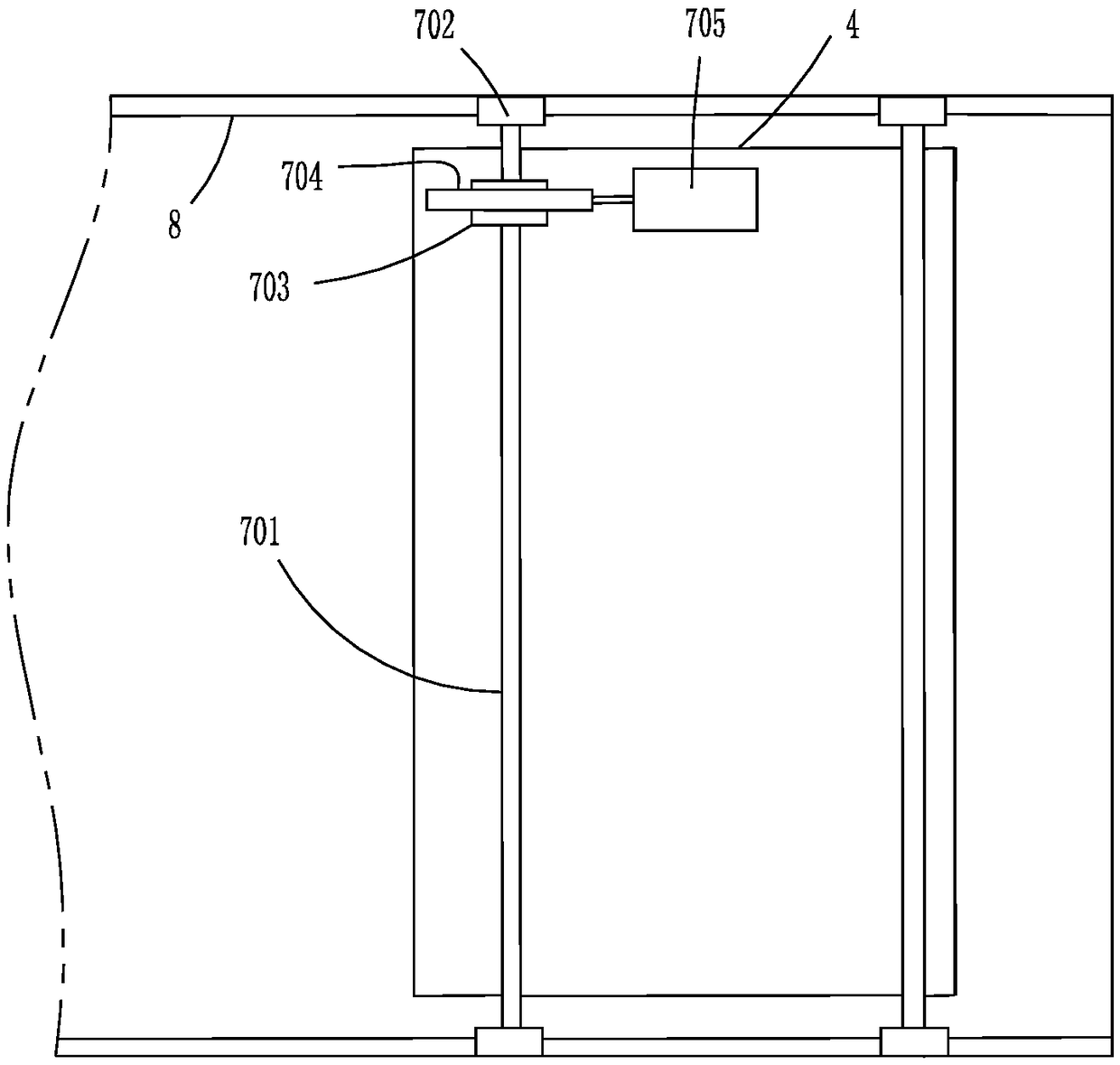

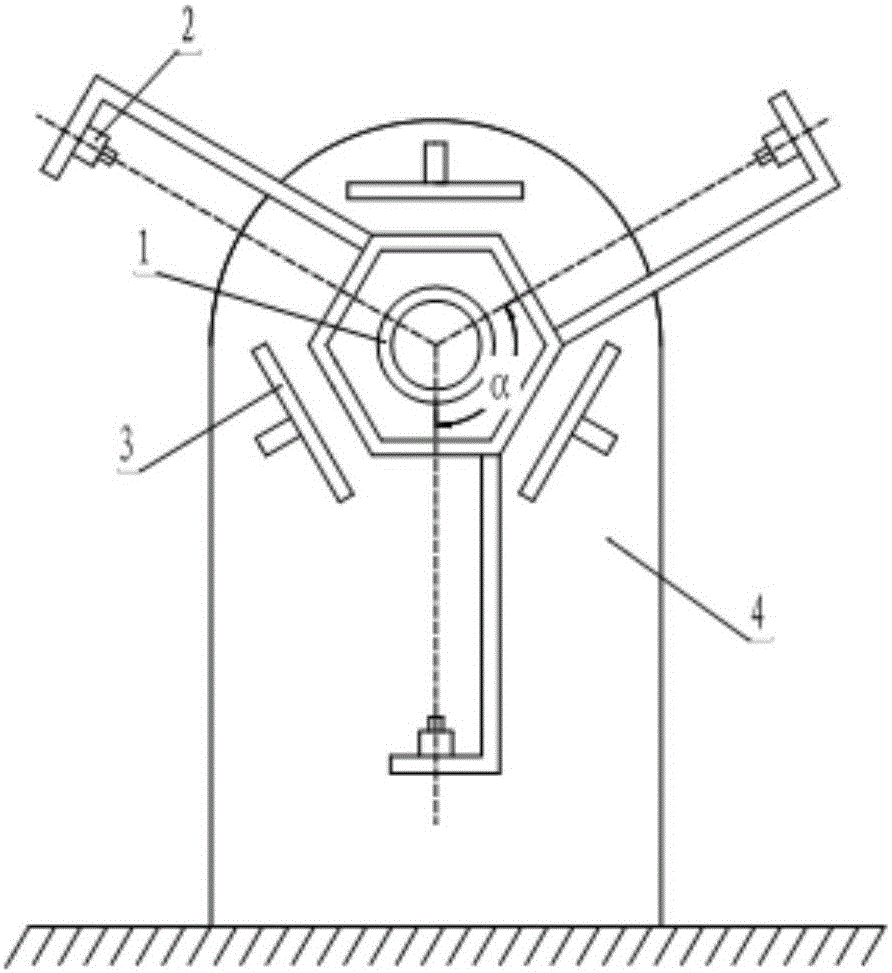

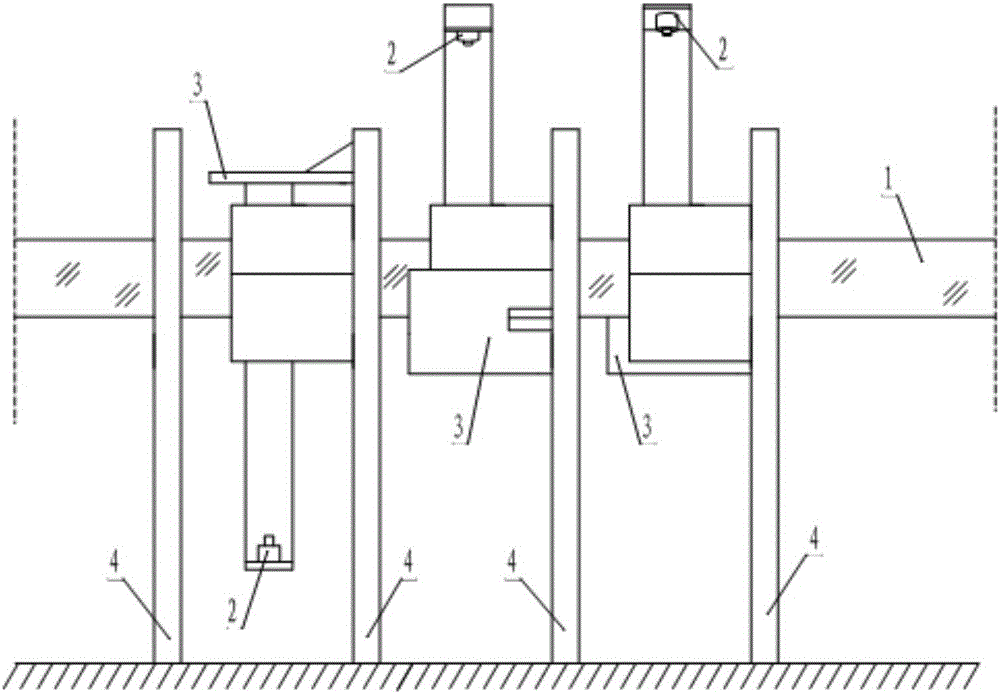

Desk-type vision function training device

The invention relates to visual training equipment, in particular to a desk-type vision function training device. The desk-type vision function training device comprises a training platform, a visiondetection device is arranged at one end of the upper surface of the training platform and comprises two columns which are vertically arranged at the two sides of the training platform, slide grooves are oppositely formed in the two opposite sides of the columns, the two ends of an adjusting plate are in vertical sliding fit with the interiors of the slide grooves, a long-strip-shaped hole horizontally penetrates through the middle of the adjusting plate, the vision detection device comprises two discs, spherical lenses are distributed in the radial direction of the discs, the center of circleof each disc is rotatably installed on the adjusting plate, and the vision detection device further comprises a disc rotating mechanism which is used for driving the discs to rotate around the centerof circle of the discs themselves and a disc moving mechanism which is used for driving the discs to move in the direction close to or away from the long-strip-shaped hole, and also comprises a heightadjusting mechanism which is used for adjusting the height of the adjusting plate.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

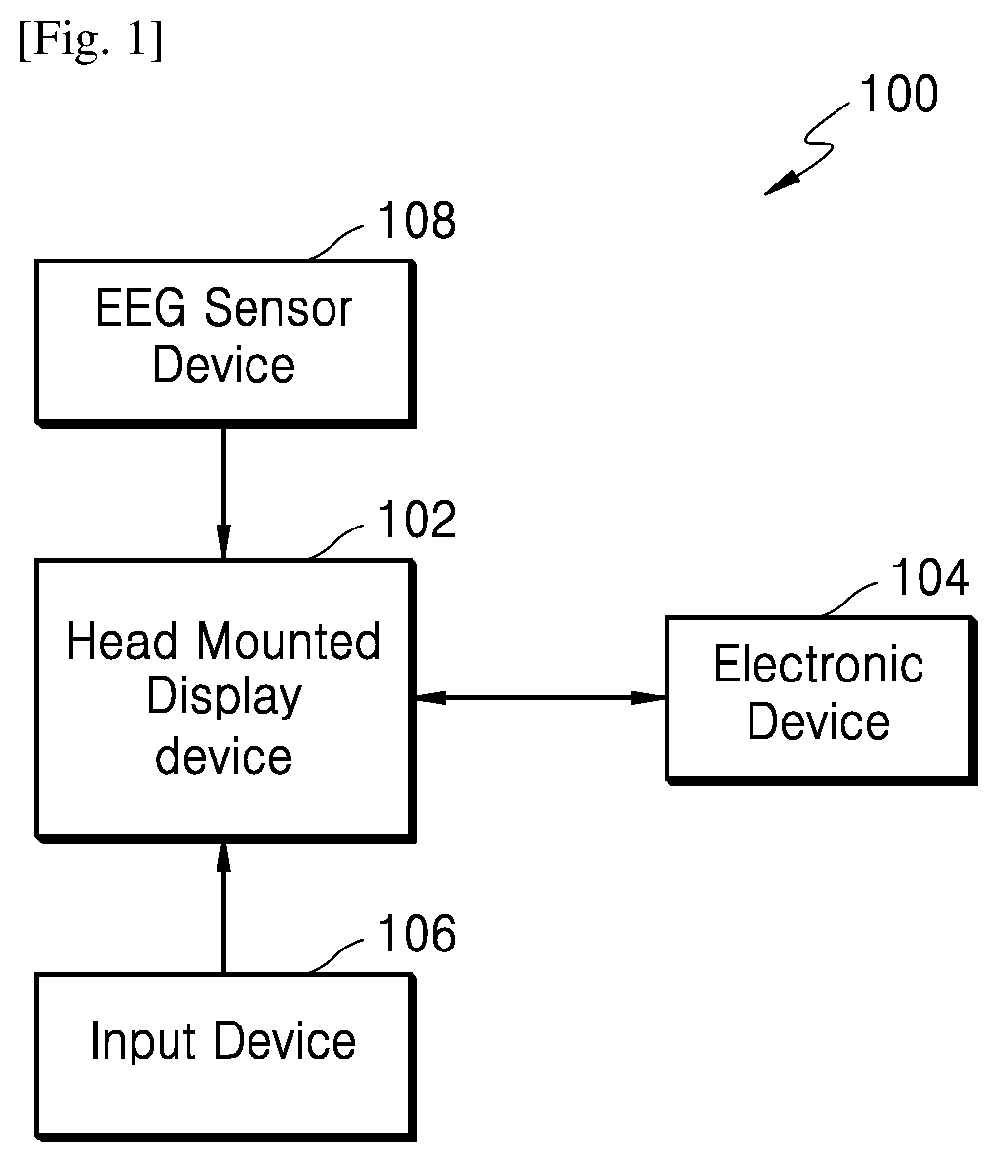

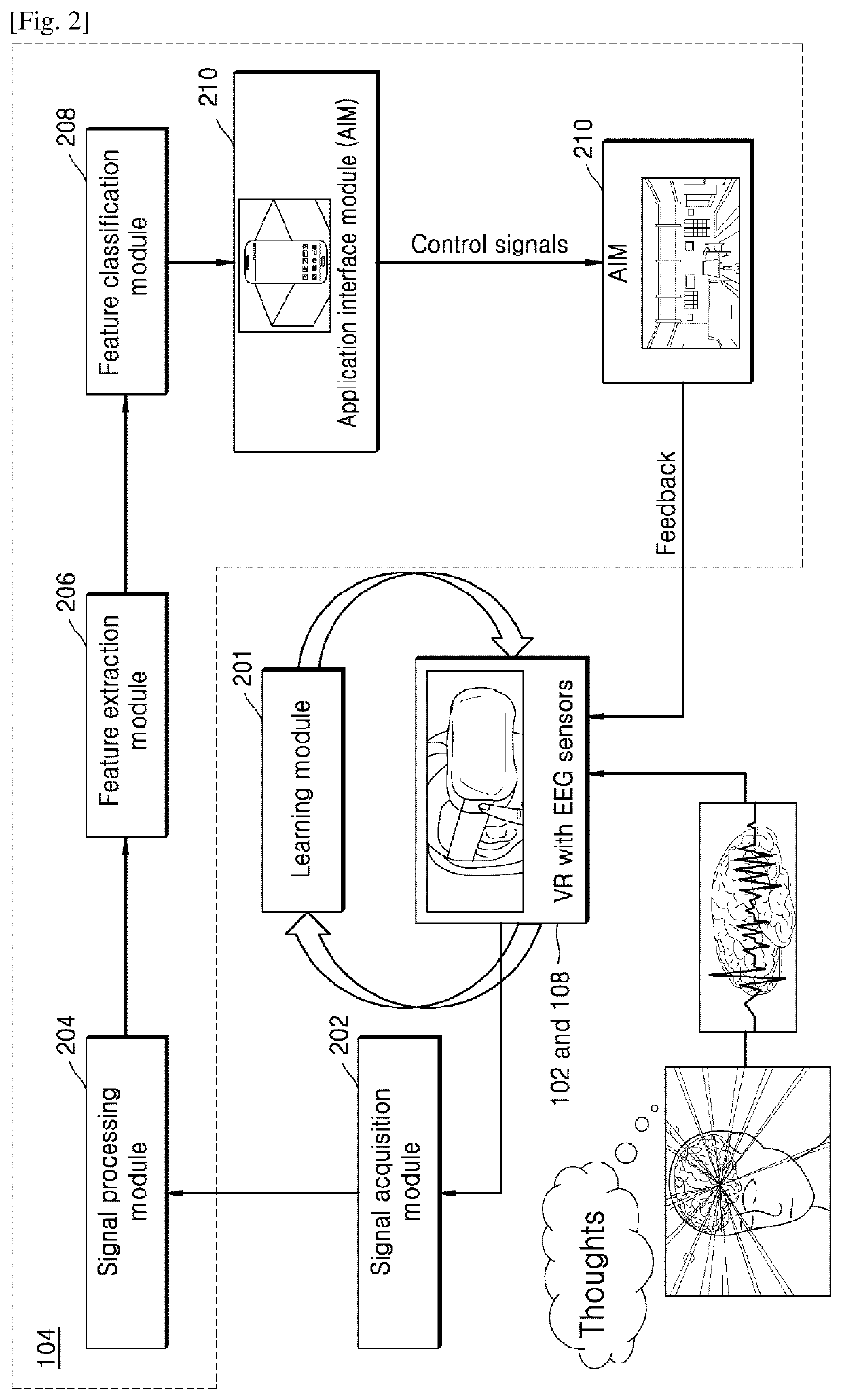

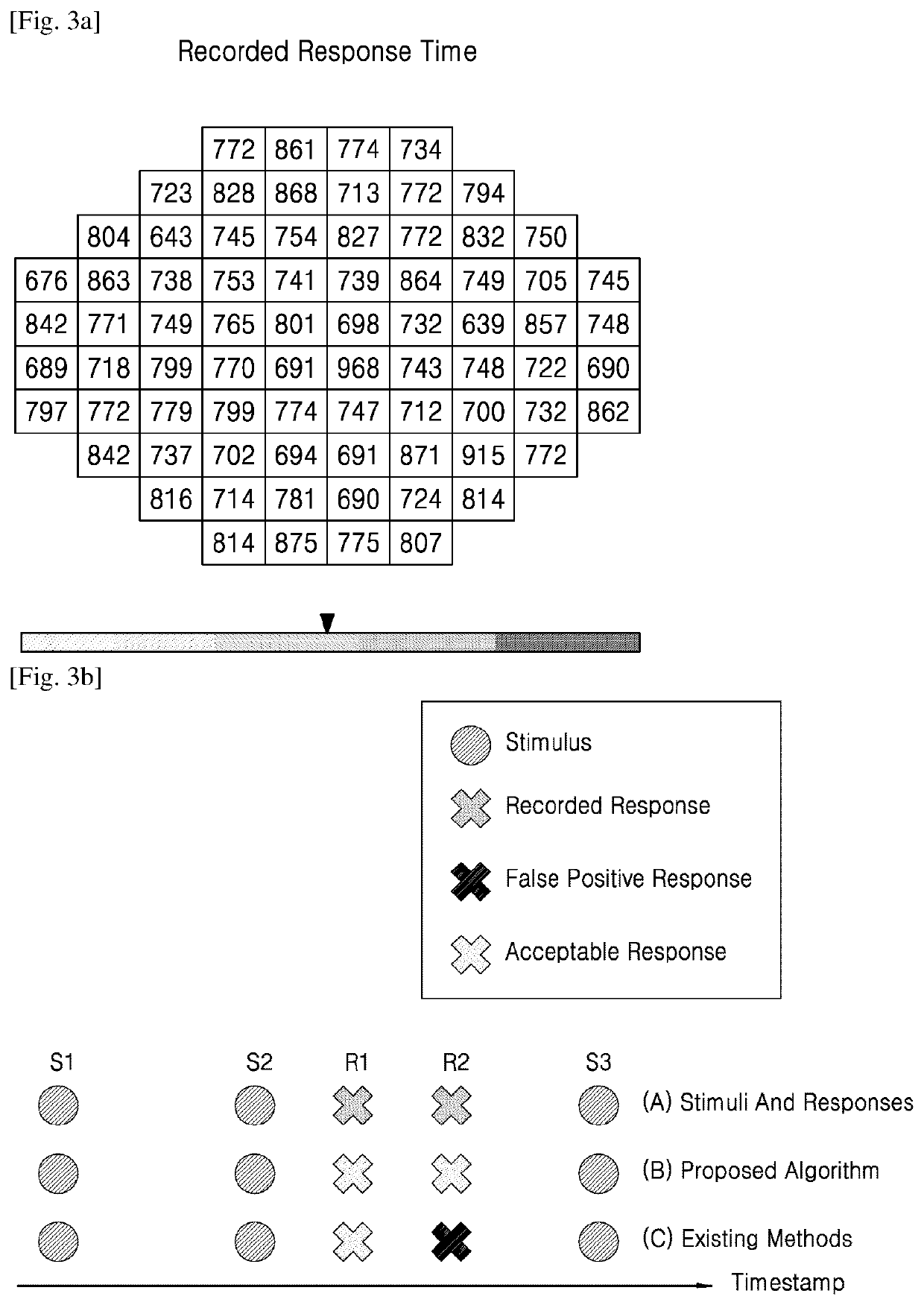

Systems and methods for determining defects in visual field of a user

InactiveUS20200073476A1Avoid eye strainInput/output for user-computer interactionDetails for portable computersVisual field lossGraphics

Embodiments herein disclose systems and methods for determining defect in visual field of a user. The present disclosure relates to field of medical analysis and diagnostics and more particularly relates to systems and methods for determining neurological visual diseases of the user by using the Virtual Reality (VR) display device such as a Head Mounted Display (HMD) device. The method includes providing visual stimuli along with a center weighted object to test the neurological visual disease of the user. The method includes generating a heat map or a graph to display region of blind spot in the eye of user.

Owner:SAMSUNG ELECTRONICS CO LTD

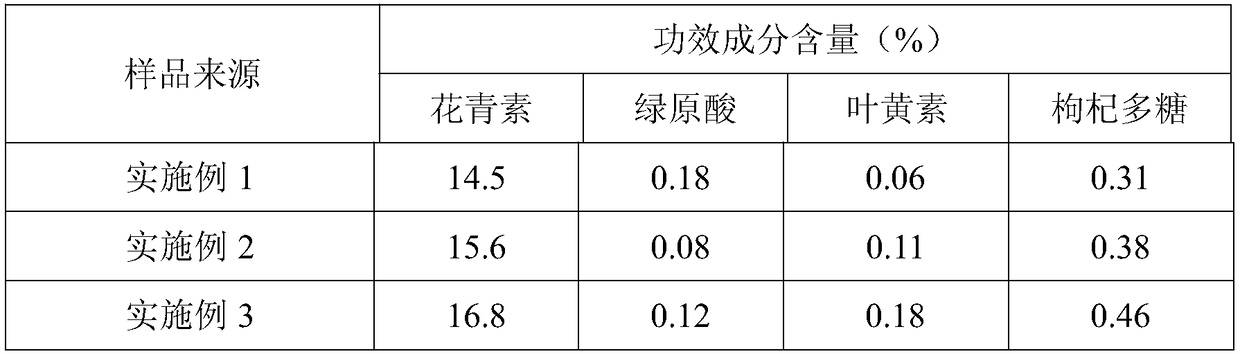

Tabletted sweets capable of alleviating asthenopia as well as preparation method and application of tabletted sweets

The invention relates to the technical field of foods, and discloses tabletted sweets capable of alleviating asthenopia. The tabletted sweets comprise the following raw materials in parts by weight: 40-50 parts of blueberry fruit juice powder, 1-5 parts of chrysanthemum powder, 20-30 parts of Chinese wolfberry fruit powder, 1-5 parts of grape seeds, 0.1-1 part of xanthophyll, 5-10 parts of dietaryfibers, 10-20 parts of D-mannitol, 5-10 parts of maltodextrin and 0.1-1 part of magnesium stearate. The invention further discloses a preparation method of the tabletted sweets and an application ofthe tabletted sweets in the respect of alleviating asthenopia. The tabletted sweets have the beneficial effects of being comprehensive in nutrient components, an original ecology low-temperature processing technology is adopted, the tabletted sweets conform to the proportion of promoting blood circulation for removing blood stasis, nourishing liver and kidney and removing liver fire for improvingeyesight in traditional Chinese medicines, and nutrient components of the raw materials are guaranteed not to be destroyed, so that the efficacy of promoting blood circulation for removing blood stasis and removing liver fire for improving eyesight can be achieved.

Owner:江苏海王健康生物科技有限公司

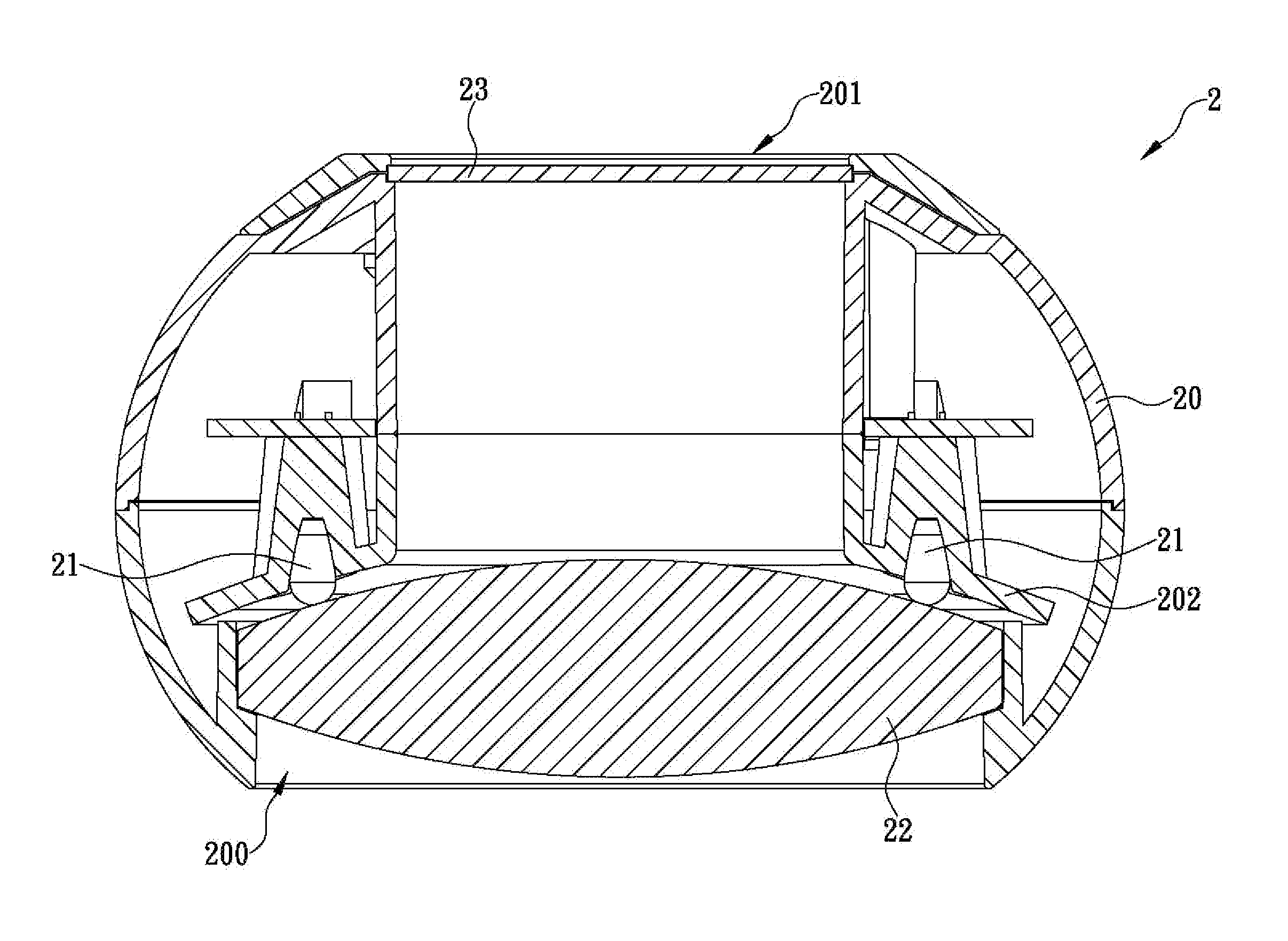

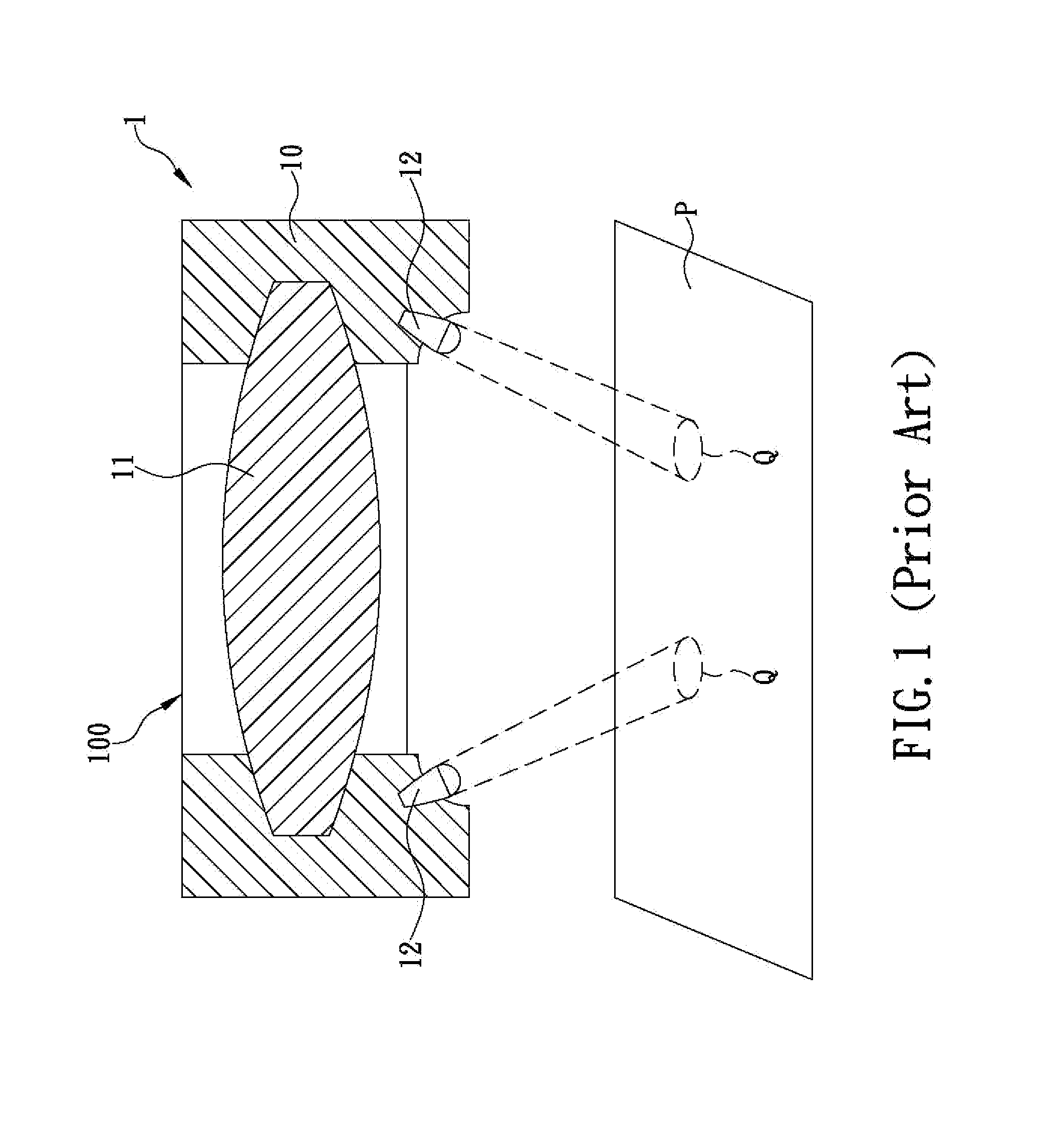

Magnifying glass with lighting function

InactiveUS20130329309A1Increase production costAvoid eye fatigueMagnifying glassesMagnifying glassProject area

The present invention is to provide a magnifying glass with a lighting function, which includes a housing having a front side formed with an objective aperture, a rear side formed with a viewing aperture which is opposite to and in communication with the objective aperture, and a fixing portion provided therein and facing the objective aperture; a plurality of light-emitting elements fixed to the fixing portion and able to emit visible light outward of the objective aperture; and a convex lens fixed to the housing at a position corresponding to the objective aperture and in front of the light-emitting elements. Thus, the visible light emitted by each light-emitting element is refracted by the convex lens and then projected onto the surface of an object to form a light projected area on the object, wherein the light projected areas overlap with one another to illuminate the surface of the object uniformly.

Owner:HUANG KUAN DI +1

Method for Designing Spectacle Lens, and Spectacles

ActiveUS20090086162A1Avoid eye strainPrevent surfaceSpectales/gogglesEye diagnosticsUses eyeglassesEyeglass lenses

A method for designing a spectacle lens that includes an optical convex surface on an object side of the spectacle lens and an optical concave surface on an eye side of the spectacle lens and is mounted in a spectacle frame in a manner tilting with respect to a forward sight line, the optical convex surface being spherical, the optical concave surface being optically curved according to a prescription, the method including: defining a design reference point at an intersection of the optical concave surface and the forward sight line; and determining an angle formed by a tangent line at the design reference point and a perpendicular plane perpendicular to the forward sight line as a lens tilt angle θ with which the spectacle lens is mounted in the spectacle frame.

Owner:HOYA LENS MFG PHILIPPINES

Vision Protection Method and System Thereof

The vision protection method and system thereof is provided to ensure a viewer to rest his / her eyes after viewing on an electronic device for a certain period, wherein the eyesight protection method includes the steps of detecting one of more working parameters of the viewer in responsive to a preset working threshold in a working mode of the electronic device during the viewer is working on a current work displaying by the electronic device; switching the working mode of the electronic device to a resting mode; and switching the electronic device from the resting mode back to the working mode to resume the display of the current work of the electronic device. Therefore, the viewer is enforced to rest his / her eyes after every certain period.

Owner:EYES4LIVES INC

Vision protection method and system thereof

A vision protection method includes the steps of tracking at least one of eye activities of the viewer of the electronic device via a working condition detector; detecting possible eye conditions based on pupilary light reflex and responses; determining eye fatigue due to the eye activities of the viewer of the electronic device in a working mode of the electronic device; and generating a viewer eye result in response to the eye activities and possible eye conditions.

Owner:EYES4LIVES INC

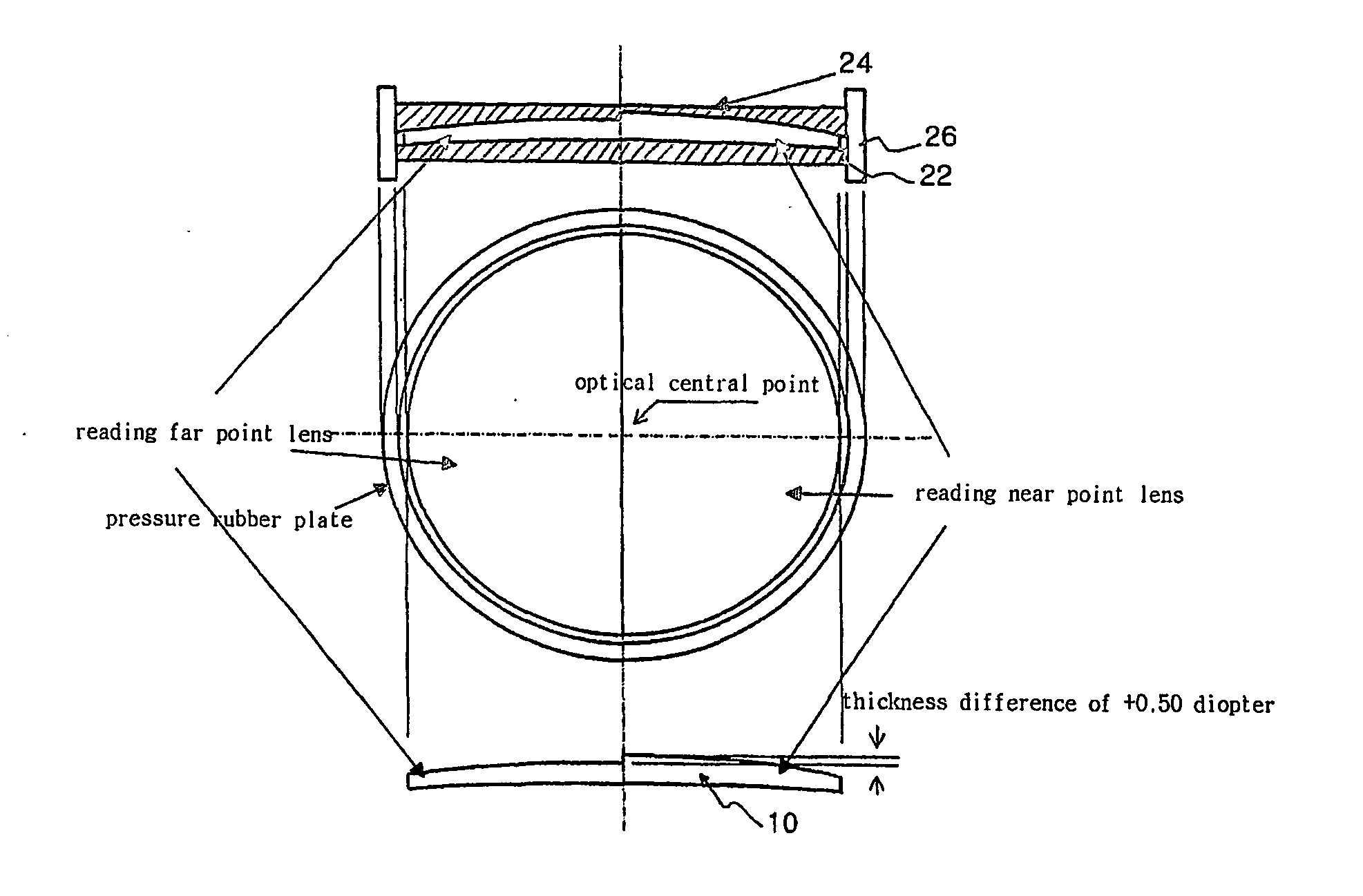

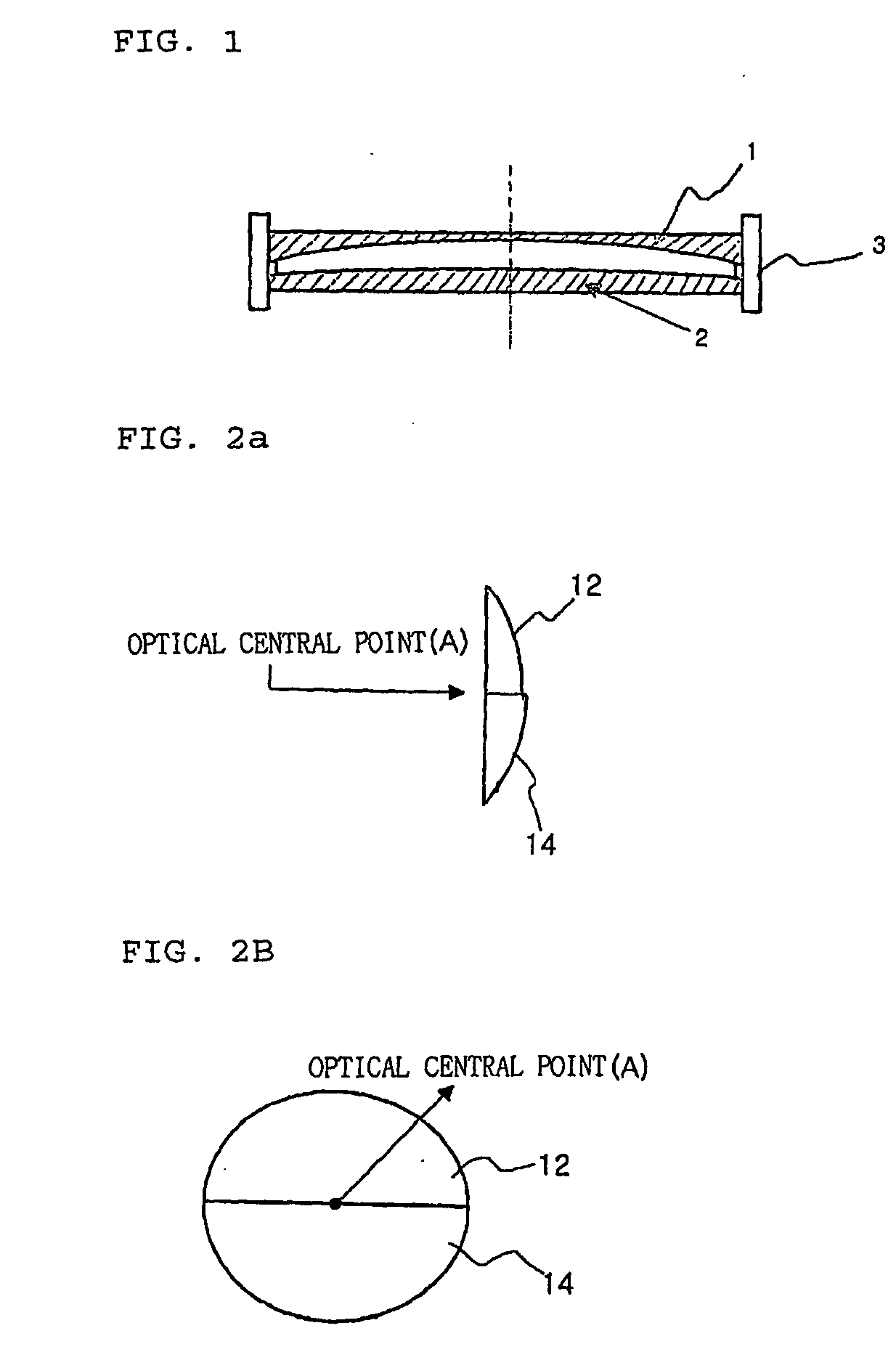

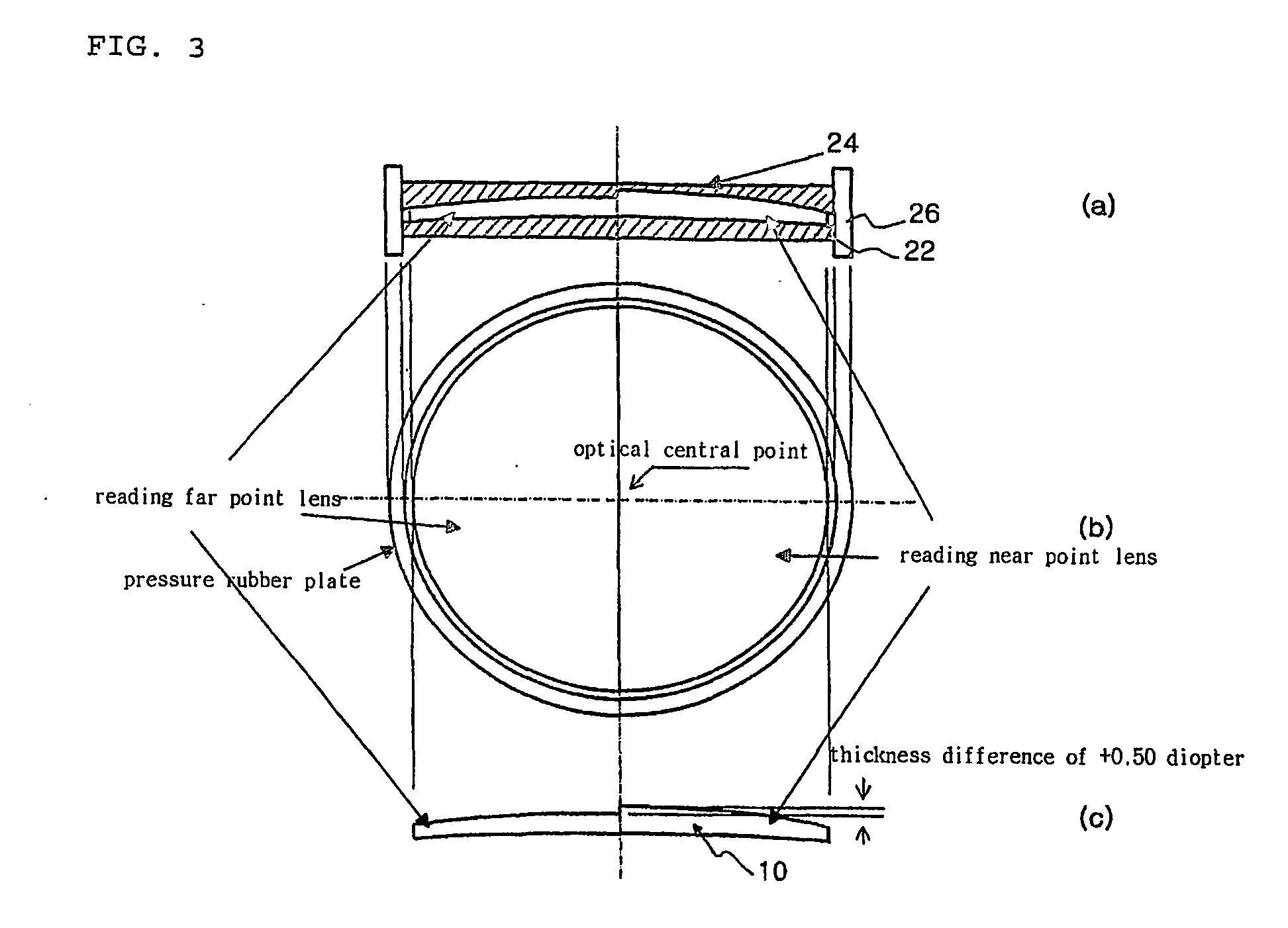

Single focus compound lens and mold

InactiveUS20060073231A1Avoid eye strainAvoid fatigueSpectales/gogglesConfectioneryPhysicsNearest point

Disclosed is a single focus compound lens and a mold for manufacturing the single focus compound lens, where the single focus compound lens has a reading far point diopter lens and a reading near point diopter having different diopters that are integrally molded to have the same optical central point and the mold has the two divided areas with respect to the optical central point, each of the two areas forming an inner peripheral surface having a difference in curvature and thickness corresponding to the diopter difference, such that near distance works like reading or doing with a computer can be accomplished without any trouble and the fatigue of eyes caused due to the failure of correspondence of focuses can be prevented.

Owner:JOE HYUN SOO

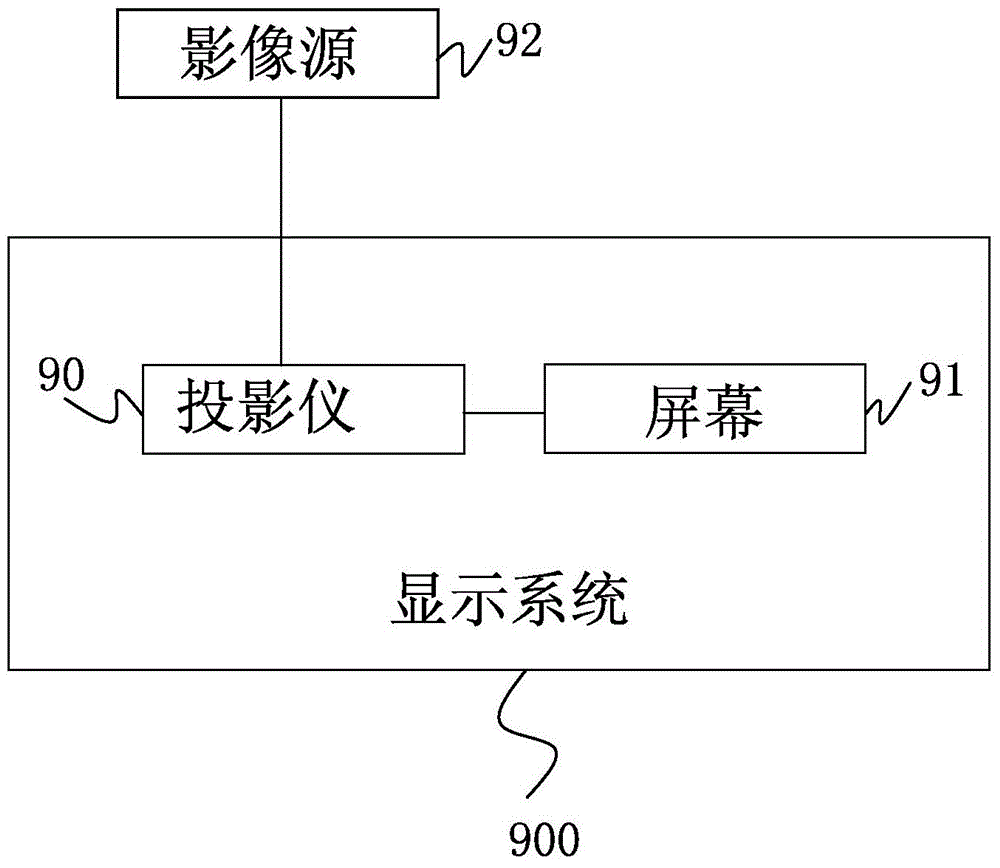

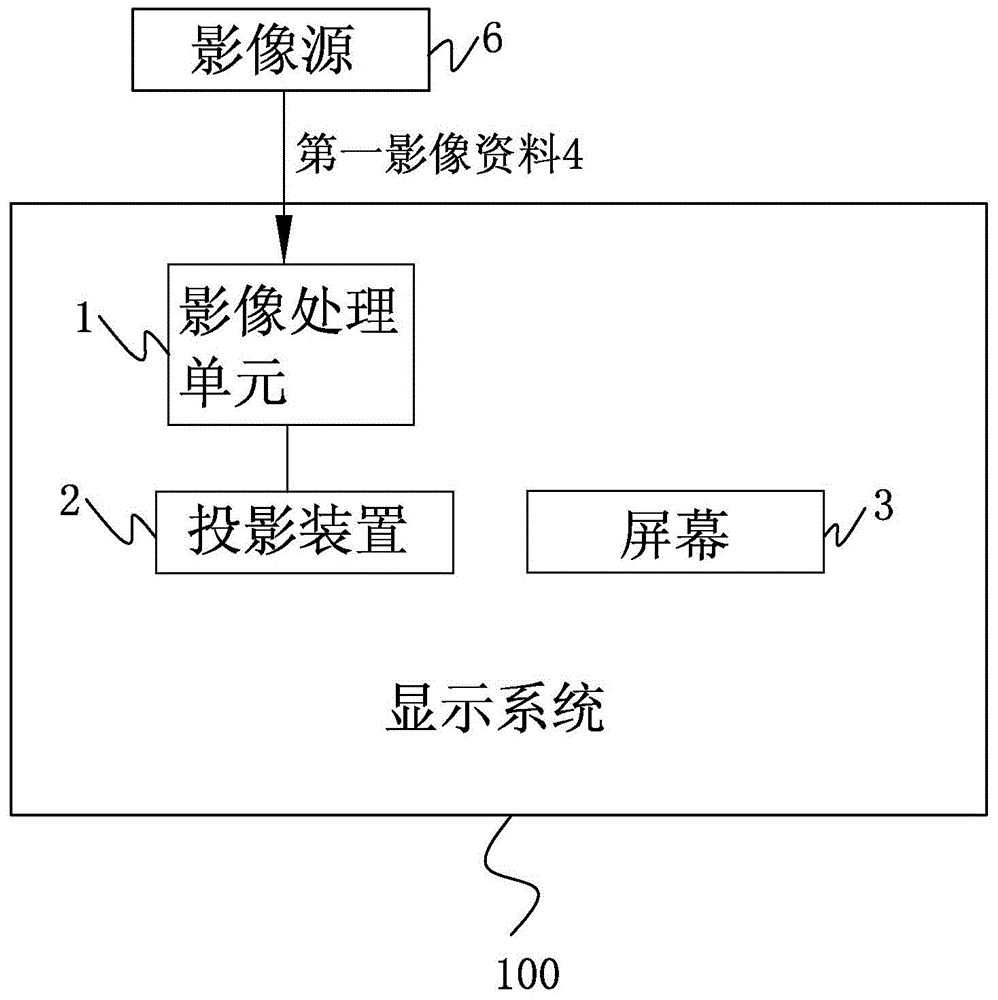

Projection system and control method thereof

ActiveCN105204162APixel density reductionPixel simplificationOptical elementsPixel densityProjection system

The invention relates to a projection system and a control method thereof, in particular to a projection system capable of automatically simplifying projection content and a control method of the projection system. The control method of the projection system includes the following steps that firstly, first image data are received; secondly, pixel density of the first image data is reduced so that second image data can be formed; thirdly, the second image data are projected to a transparent screen.

Owner:吴江科技创业园管理服务有限公司

Drawing platform for digital building fundamental research

InactiveCN111820599APrevent hittingSave spaceLighting support devicesDigital data processing detailsPaper sheetLight equipment

The invention relates to a drawing platform for digital building fundamental research. The drawing platform comprises a lower drawing platform and a fixing mechanism, the upper end of the lower drawing platform is connected with an upper drawing platform through a hinge, magnet blocks are installed in the upper drawing platform and the lower drawing platform, a computer containing mechanism is installed at the upper end of the upper drawing platform, and a lighting mechanism is installed behind the lower drawing platform. The beneficial effects of the drawing platform that according to the drawing platform for digital building fundamental research, the equipment can be folded and unfolded; when the equipment is not used, the space utilization can be reduced; an angle of the equipment drawing platform can be adjusted, which is convenient for a drawer to draw, the drawing platform can rotate to facilitate surrounding personnel to observe drawings, meanwhile, the drawing platform is provided with lighting equipment, storage equipment and a notebook placement table, workers can use the drawing platform more conveniently, and meanwhile, the drawing platform can prevent paper from beingbent and make the drawings smoother.

Owner:福建省泷澄建设集团有限公司

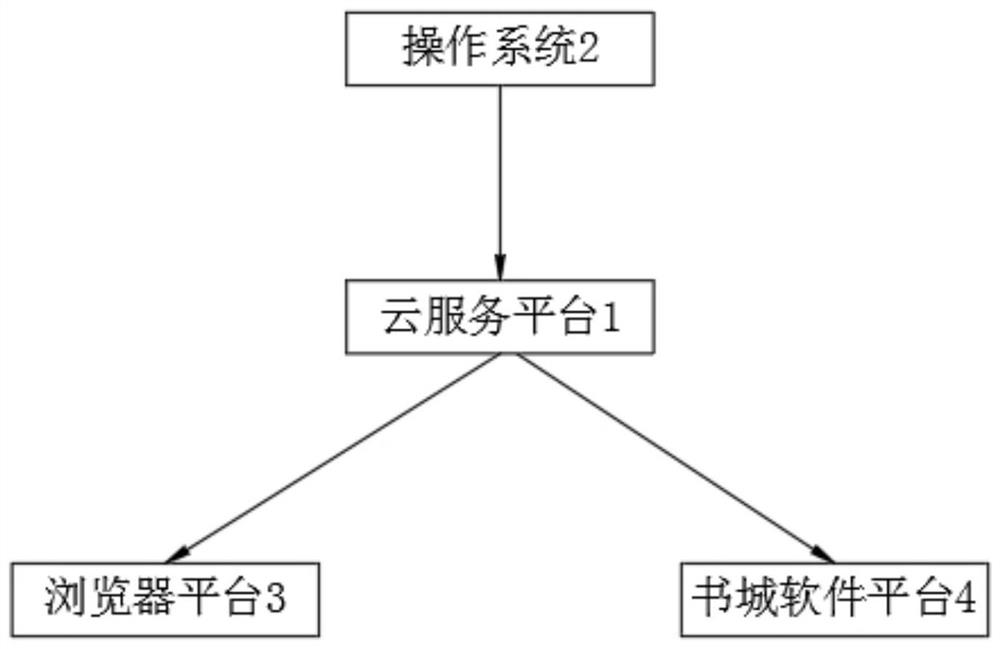

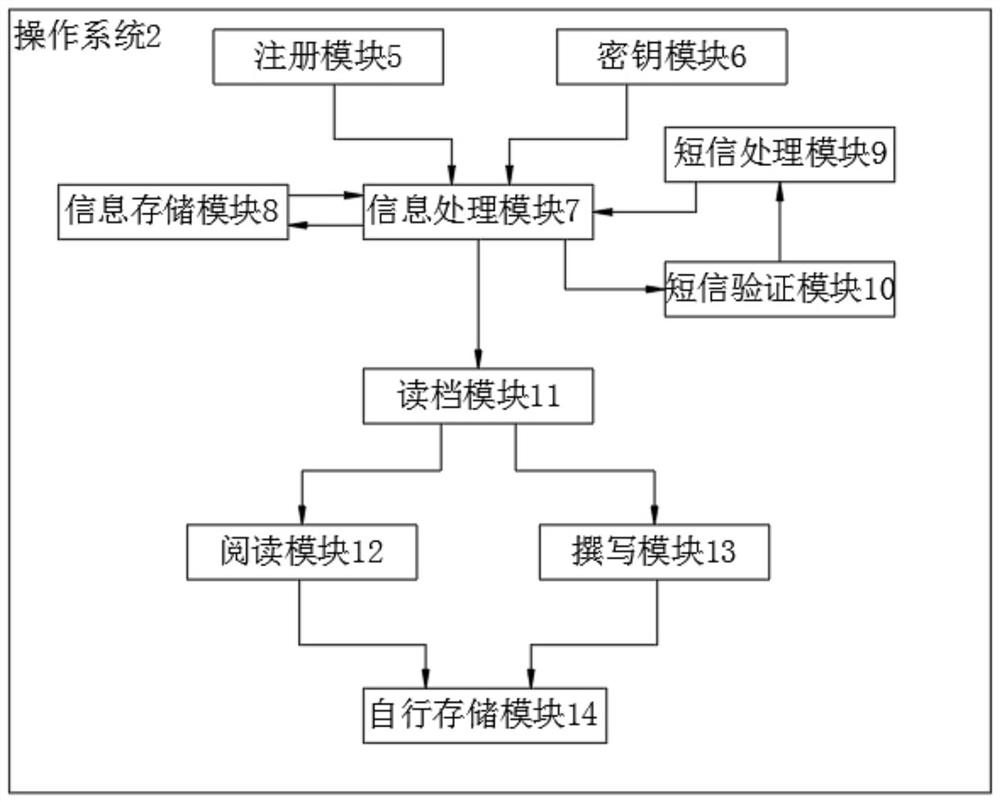

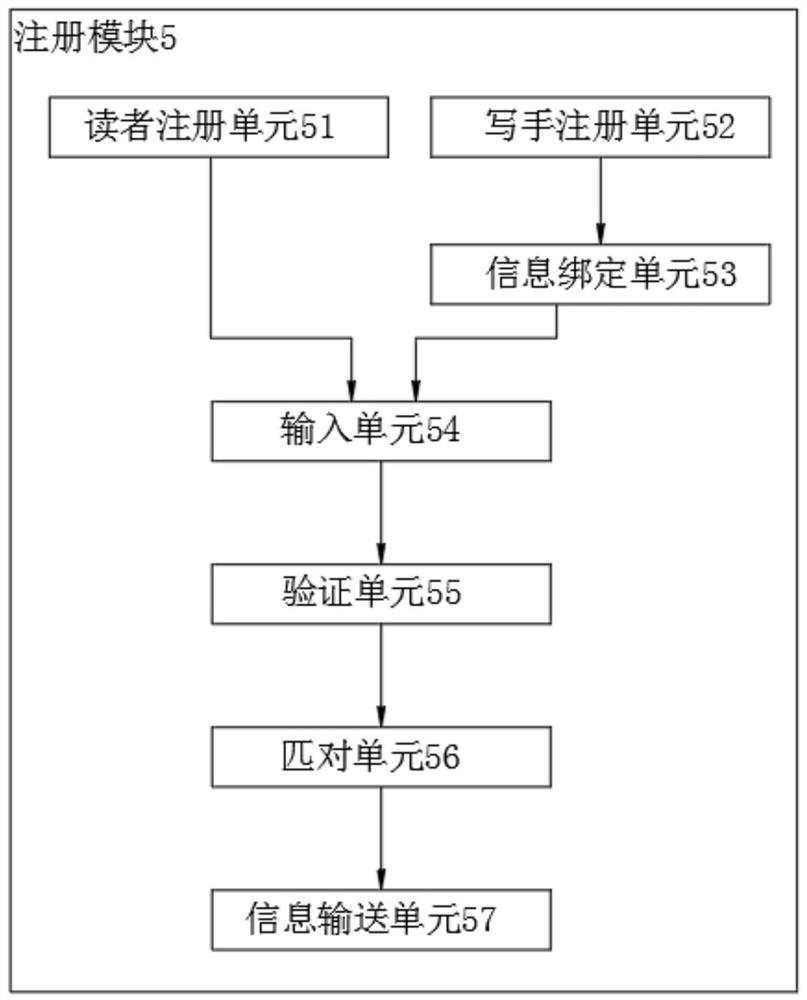

Online reading system and method based on cloud computing

PendingCN111680235AIncrease reading pleasureAvoid eye strainDigital data protectionWebsite content managementCloud computingEye Fatigue

The invention discloses an online reading system and method based on cloud computing. The invention relates to the technical field of online reading systems. The system comprises a cloud service platform, an operating system, a browser platform and a bookstore software platform, wherein the operating system is in wireless connection with the cloud service platform, the cloud service platform is inwireless connection with the browser platform and the bookstore software platform, the operating system internally comprises a registration module and a secret key module, and the output ends of theregistration module and the secret key module are electrically connected with the input end of the information processing module. According to the system and the method, the reading pleasure of a reader in the reading process can be increased; according to the invention, the reader can take care of his / her eyes, eye fatigue is avoided, the reader can find other similar texts for reading conveniently, text information and personal information of a writer can be prevented from being stolen, copying of documents by external personnel is effectively avoided, and personal rights and interests of the writer are effectively protected.

Owner:南京数娱天下网络科技有限公司

Abdominal massage chair

ActiveCN109124977APromote digestionReduce celluliteBreathing protectionTreatment roomsGastric digestionSomatosensory system

The invention discloses an abdominal massage chair, comprising a main body (1), a frame (2) is hinged on the top of the main body (1), a rotating device (5) connected with the frame (2) is arranged onthe rear side of the main body (1), rack (8) is arranged on both sides of the frame (2), rack (8) is connected with a traveling frame (4) through a traveling mechanism (7), and a 3D abdominal massagemachine (6) is connected with the traveling frame (4). The present invention has the following advantages: 1. It can promote intestinal peristalsis, improve gastric digestion and reduce abdominal redundancy; 2, that quality of the user's rest or sleep is effectively guarantee; 3, the user is comfortable when massaging on the massage chair and oxygen therapy; 4, that user can not quickly tire theeyes of the user when watching the movies and TV plays on the invention, and the effect of the user watching the movies and TV plays is good; In addition, the invention also has the advantages of adapting to a wide range of users and good safety.

Owner:浙江荣泰健康电器有限公司

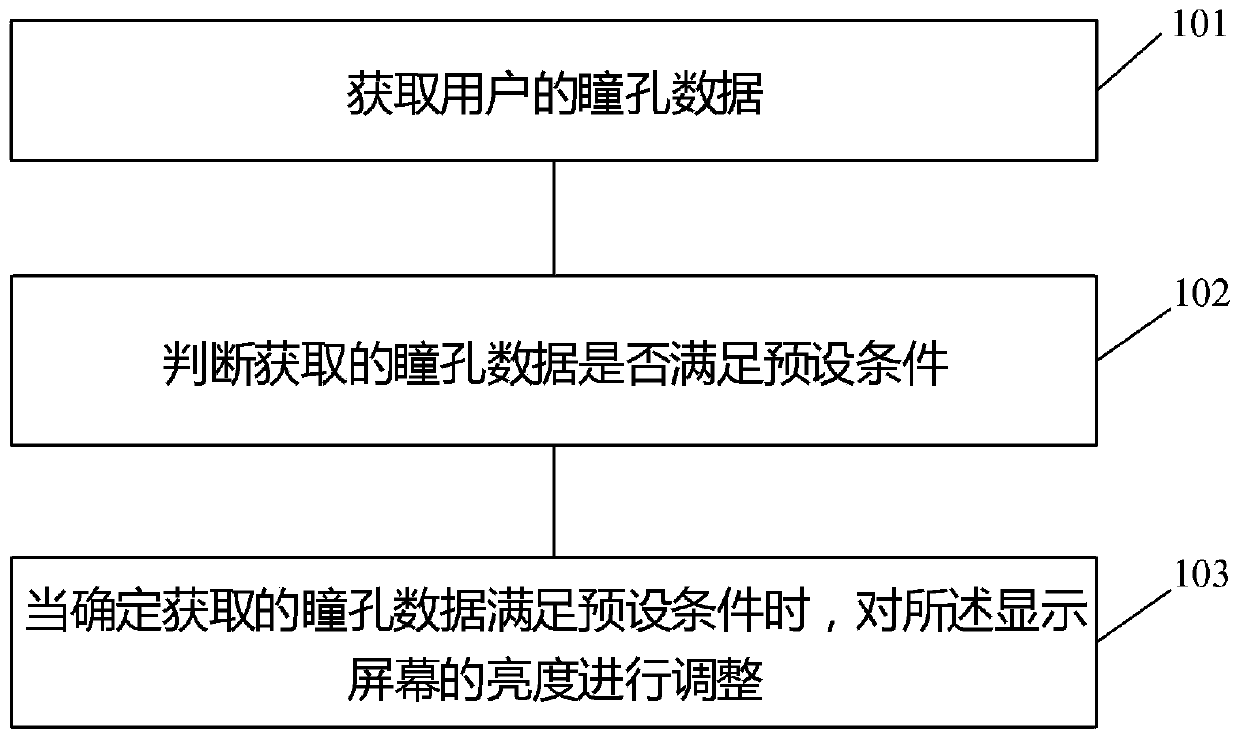

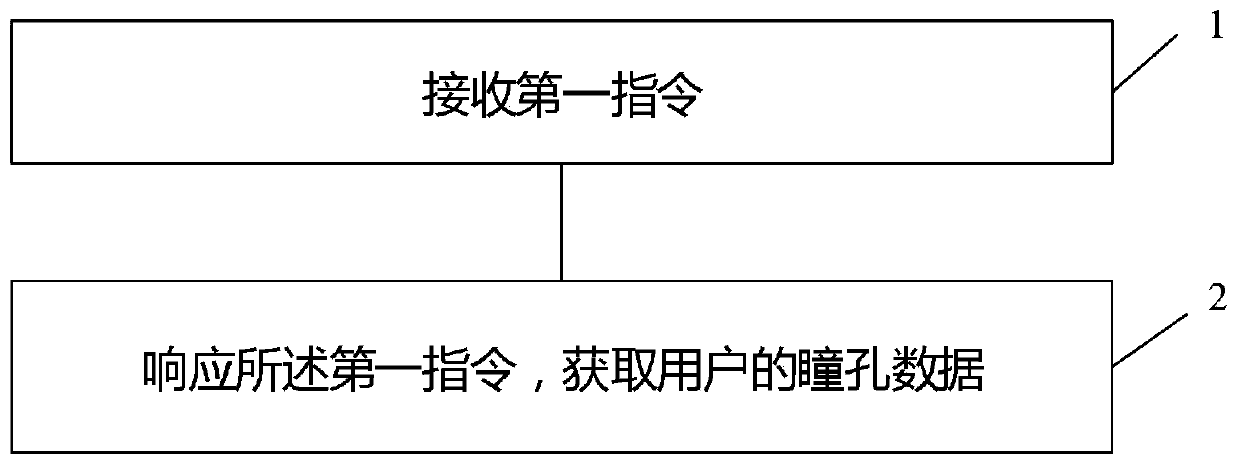

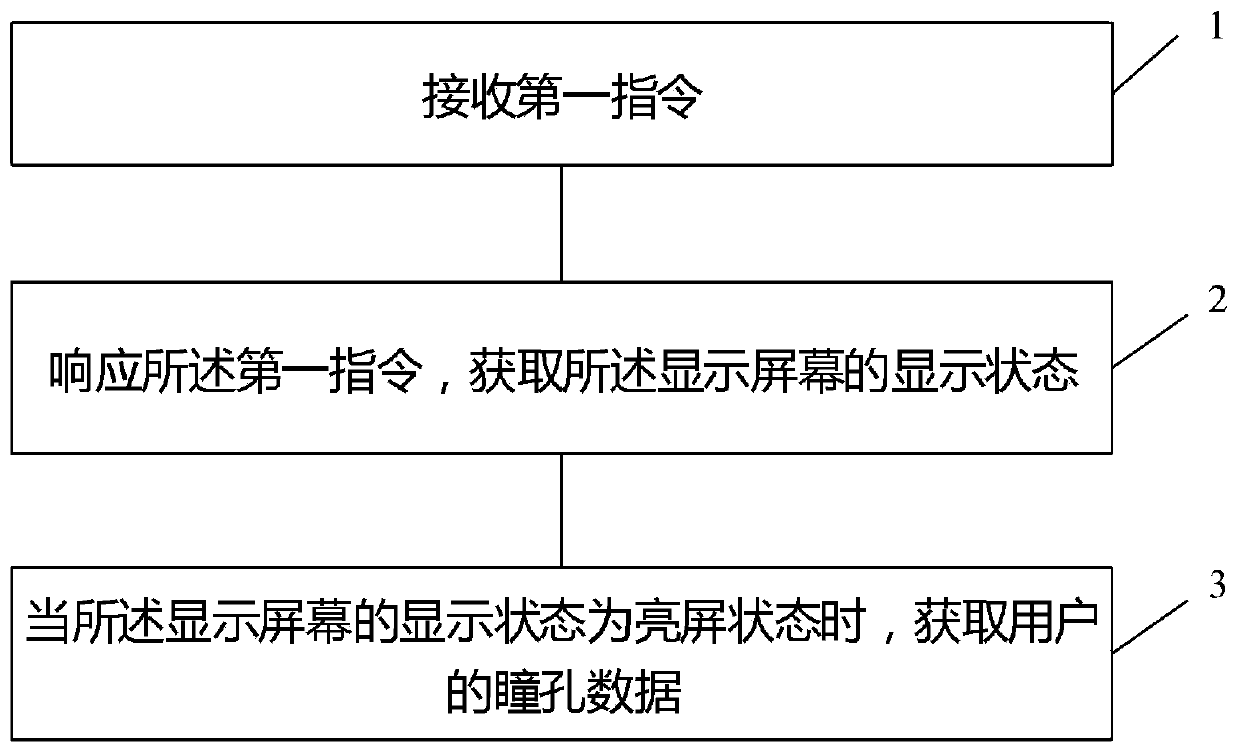

Data processing method and device, electronic equipment and storage medium

InactiveCN111414078AAvoid eye strainBrightness adjustableInput/output for user-computer interactionGraph readingComputer hardwareComputer graphics (images)

The invention discloses a data processing method and device, electronic equipment and a storage medium. The method comprises: acquiring pupil data of a user, wherein the pupil data is pupil data obtained when the user watches a display screen in the environment where the user is located; judging whether the acquired pupil data meets a preset condition or not; and when it is determined that the acquired pupil data meets a preset condition, adjusting the brightness of the display screen.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Method for detecting gas line defect of glass tube

ActiveCN106018437AKeep healthyAvoid eye strainMaterial analysis by optical meansProduction linePhysical well being

The invention relates to a method for detecting a gas line defect of a glass tube, and belongs to the technical field of measurement and testing. The method comprises the following operation steps of: a, by three groups of shooting equipment arranged on a glass tube pulling wire, carrying out shooting on the glass tube and acquiring image information according to a set frequency, and transmitting the image information to a processor; b, by the processor, analyzing each image information and judging whether a gas line exists on a glass tube section corresponding to the each image information; c, when a judgment result is that the gas line does not exist on the glass tube, determining the section of the glass tube as a qualified product; d, when the judgment result is that the gas line exists on the glass tube, by the processor, calculating out a length L1 of the gas line, and comparing the length L1 with a preset gas line length standard value L; e, when N1 is greater than or equal to N, determining that the section of the glass tube is an unqualified product; f, when N1 is smaller than N, determining that the section of the glass tube is a qualified product. The method is high in reliability and high in working efficiency, and not only can be coordinated with the beat of a production line, but also ensures body health of an operator.

Owner:沧州四星玻璃股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com