Preparation device and preparation method of construction waste recycled aggregate sound insulation mortar

A technology for recycled aggregates and construction waste, applied in clay preparation devices, unloading devices, mixing operation control devices, etc., can solve problems such as automatic crushing of aggregates, automatic dredging of blockages, inconvenient feeding adjustment, etc., to achieve Improved adjustability, better mixing, and improved production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

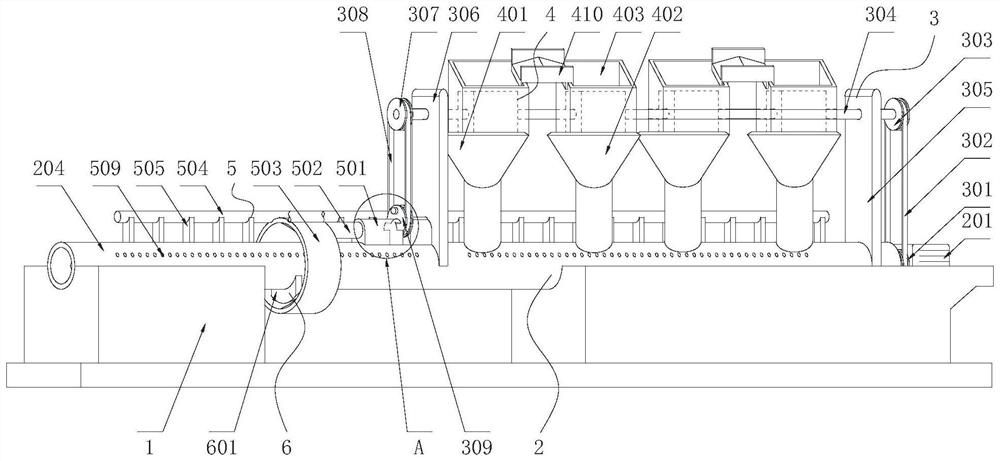

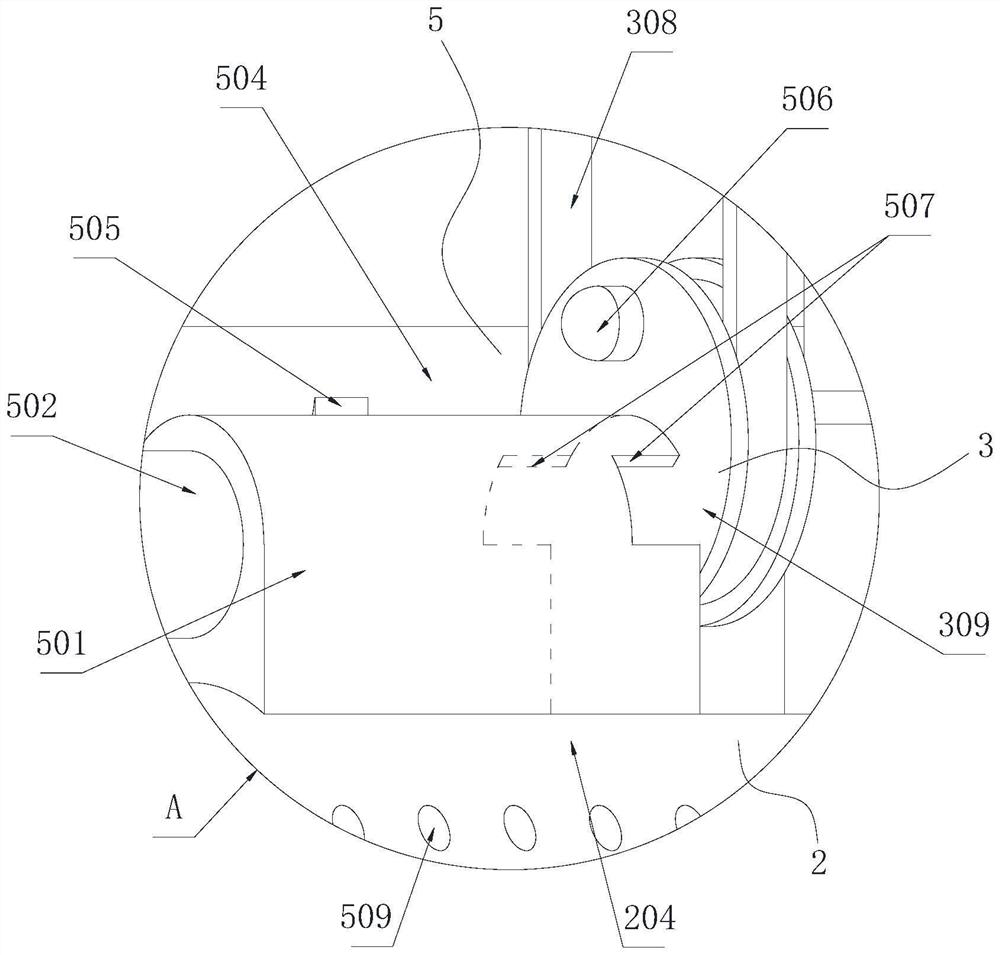

[0050] like figure 1 , Figure 4 with Figure 5 As shown, the present embodiment proposes a preparation apparatus of a construction waste regenerated aggregate sound laminating mortar and a preparation method thereof, including the support seat 1 and the feed mechanism 2, and the surface of the support seat 1 is fixedly mounted, and the feed mechanism 2 is applied. Connecting the transmission assembly 3 in the middle, the middle of the transmission assembly 3 is attached, and the end of the transmission assembly 3 is attached to the end of the transmission assembly 5, and the feed mechanism 2, the feed driving assembly 4 and the dredge assembly 5 are synchronized by the transmission assembly 3. Working, the dredge assembly 5 is located on the front side of the feed mechanism 2; the internal activity of the feed mechanism 2 is attached to the crushing mechanism 6, and the crushing mechanism 6 is located inside the dredge assembly 5, and the dredge assembly 5 can also drive the crushi...

Embodiment 2

[0052] Next, in conjunction with the specific mode of operation, further introduction of the scheme in Example 1 is shown in detail below.

[0053] like figure 1 with Figure 4 As shown, as a preferred embodiment, in the above manner, further, the feed mechanism 2 includes a motor 201, a connecting rod 202, a horizontal push plate 203, a conveying conduit 204; the motor 201 bolt is fixed to the right of the support seat 1. On the side, the connection rod 202 is fixed to the output shaft of the motor 201, and the connecting rod 202 and the horizontal push plate 203 are driven by the motor 201 drive, thereby fixing the bone material as a whole, and the outer side of the connecting rod 202 is fixedly installed. The material plate 203, the outer side of the horizontal push plate 203 is provided with a conveying conduit 204, and the conveying conduit 204 is fixedly mounted on the surface of the support seat 1, and the support seat 1 is used to stabilize the conveying conduit 204.

[005...

Embodiment 3

[0062] The following embodiment with reference to specific working embodiment of the embodiment in Example 1 and Example 2 will be further described, description detailed below:

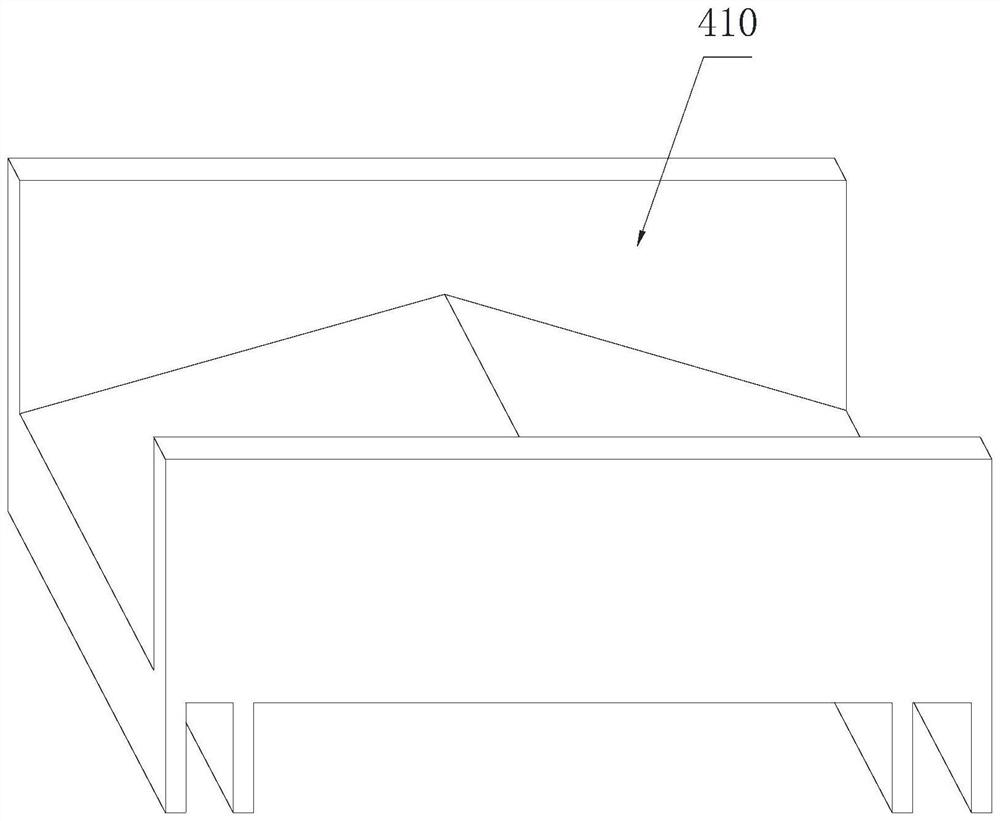

[0063] Specifically, the present apparatus and method for preparing the preparation of building waste as recycled aggregate acoustic mortar, in use: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 Shown, the driving motor 201 by the transport means inside the conduit 204 connecting rod 202 and the horizontal pusher plate 203 is rotated, conveyed forward by horizontal pusher plate 203 on the material, the inverted first aggregate from the interior of the cartridge 402 of the second in, when there are many aggregates by overlapping baffles 410, such that the aggregate can be poured simultaneously from the first cylinder 401 and second cylinder 402, and then the cement material soundproofing material from the first material, respectively cylinder 401 and the second cartridge was pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com