Water environment treatment sludge solidification pretreatment device

A pretreatment device and water environment technology, applied in water/sludge/sewage treatment, fixed/solidified sludge treatment, sludge treatment, etc., can solve the problem of reducing the use efficiency of drive motors, easy accumulation of sludge, waste of curing agent, etc. problems, to achieve the effect of reducing equipment freezes, reducing energy consumption, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

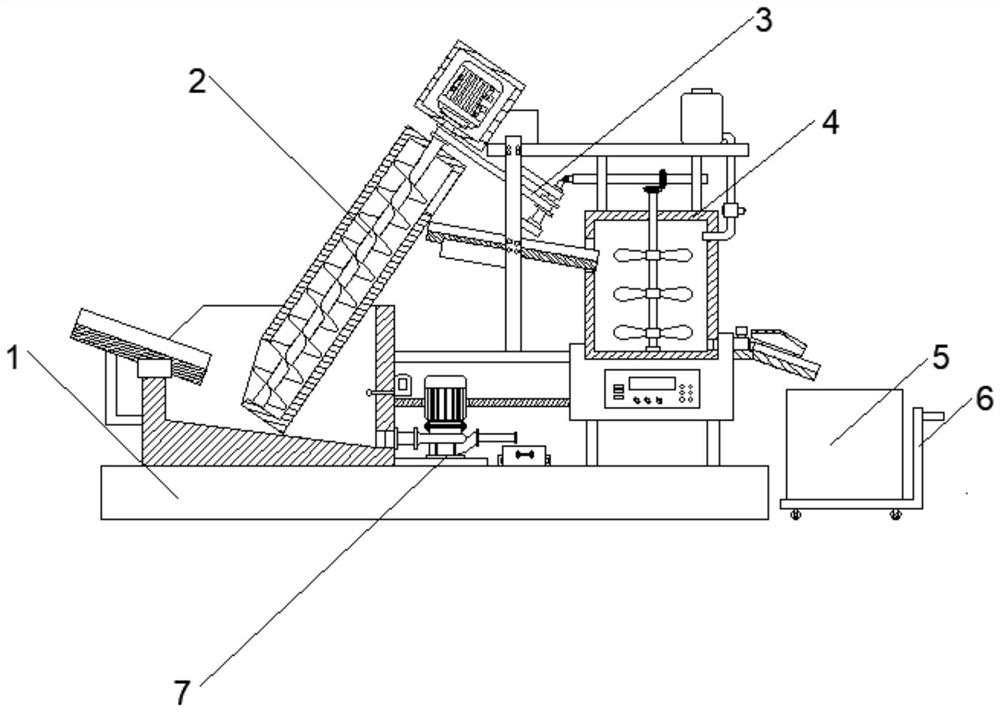

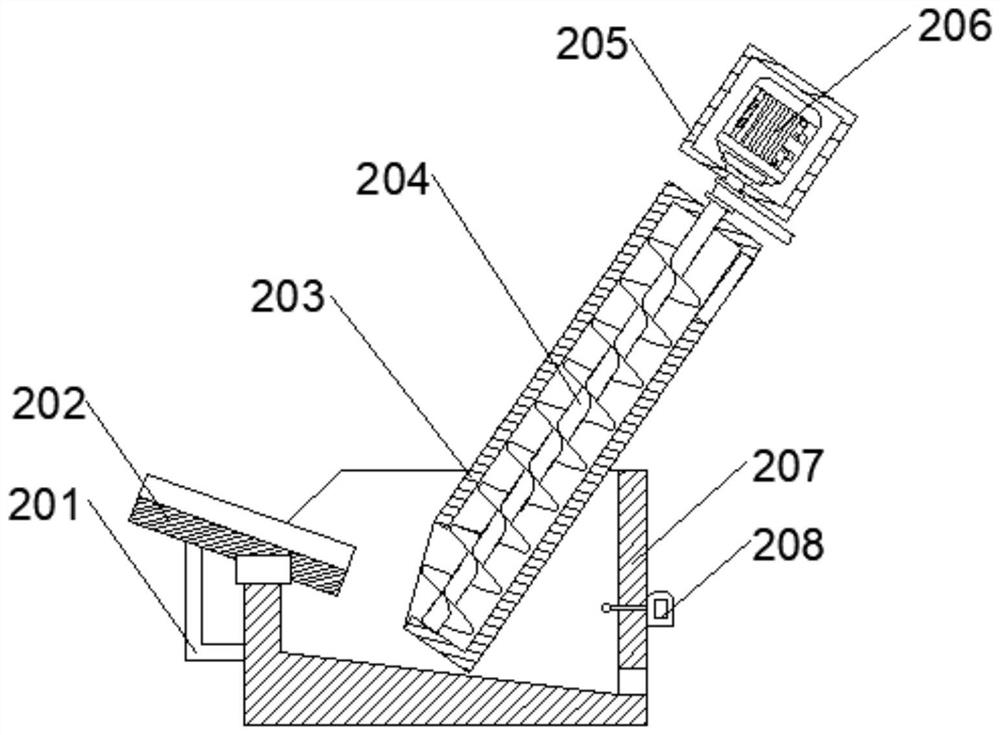

[0030] The above-mentioned input mechanism 2 includes an input box 207 fixedly connected to the bottom plate 1, a side of the input box 207 is provided with a connecting frame 201, and the top end of the connecting frame 201 is fixedly connected with a first guide plate 202, the first guide plate 202 is inclined, and The bottom end of the first guide plate 202 faces the input box 207 , the other side of the input box 207 is provided with a humidity detector 208 , and the input end of the humidity detector 208 penetrates the input box 207 .

[0031] The inner top surface of the above-mentioned input box 207 is provided with an input groove, and a mud guiding pipe 203 is fixedly installed on the groove wall of the input groove. 205, the interior of the installation box 205 is provided with a drive motor 206, the output end of the drive motor 206 runs through the installation box 205 and the mud guide pipe 203 and is fixedly connected with the top of the auger 204, the mud guide p...

Embodiment 2

[0034] The above-mentioned stirring mechanism 4 includes a mounting base 404 fixedly connected to the bottom plate 1, a control box 403 is fixedly installed on the front surface of the mounting base 404, a mixing tank 402 is connected to the top of the mounting base 404, and a stirring tank 402 is provided inside the mixing tank 402. The bottom of the inner wall of the stirring chamber is rotatably connected with a first rotating shaft 406 through a bearing, and several groups of stirring blades 407 are fixedly installed in the middle of the first rotating shaft 406, and a splash prevention mechanism 405 is fixedly installed on one side of the mounting base 404.

[0035] The above-mentioned mixing tank 402 is provided with a support plate 401, one end of the support plate 401 is fixedly installed with a mounting block, the mounting block is fixedly connected with the installation box 205, and the other end of the support plate 401 is fixedly installed with a liquid storage tank ...

Embodiment 3

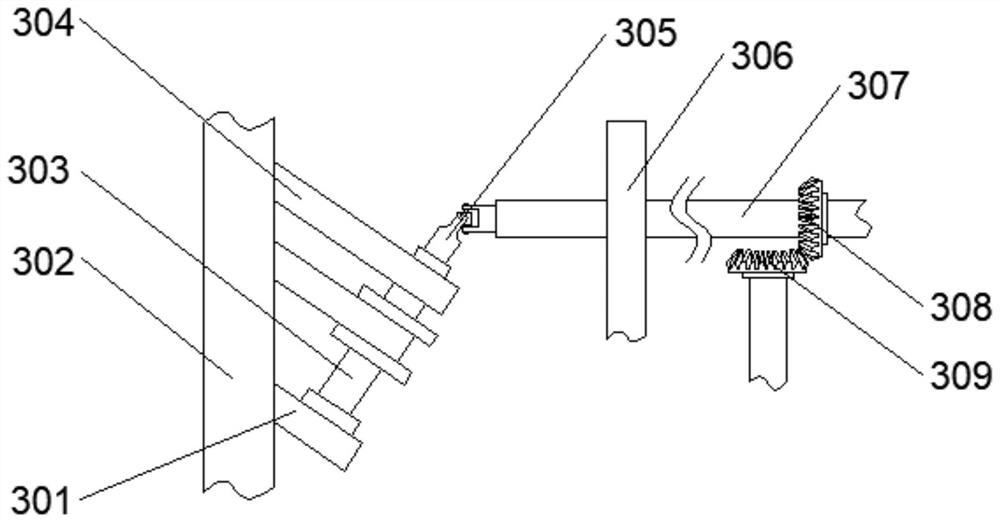

[0039] The above-mentioned transmission mechanism 3 includes a fixed frame 302 fixedly connected with the input box 207 and the mounting seat 404, the top of the fixed frame 302 is fixedly installed with a first limiting plate 301 and a second limiting plate 304, the first limiting plate 301 and the The second limiting plate 304 is all obliquely arranged, the second rotating shaft 303 is arranged between the first limiting plate 301 and the second limiting plate 304, and one end of the second rotating shaft 303 is rotationally connected with the first limiting plate 301 through a bearing, One end of the second rotating shaft 303 and the other end movably pass through the second limiting plate 304 and are movably connected with a universal joint 305 , and the second rotating shaft 303 is connected to the auger 204 through a pulley and a belt transmission.

[0040] The top of above-mentioned mixing bucket 402 is fixedly installed with two installation plates 306, and the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com