Simultaneous distillation and extraction device and method for extracting volatile oil by using same

An extraction device and volatile oil technology, which is applied in the field of plant volatile oil extraction devices, can solve problems affecting product quality, water consumption, and unstable air pressure, and achieve scientific and reasonable device settings, improved yield and quality, and balanced and constant pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

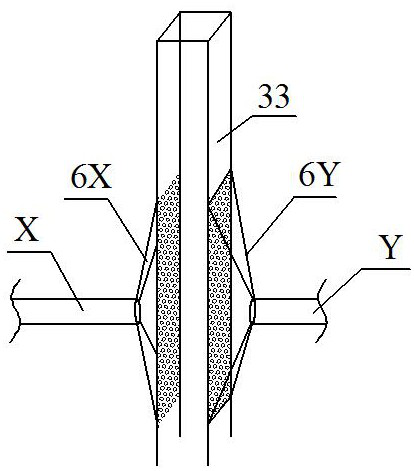

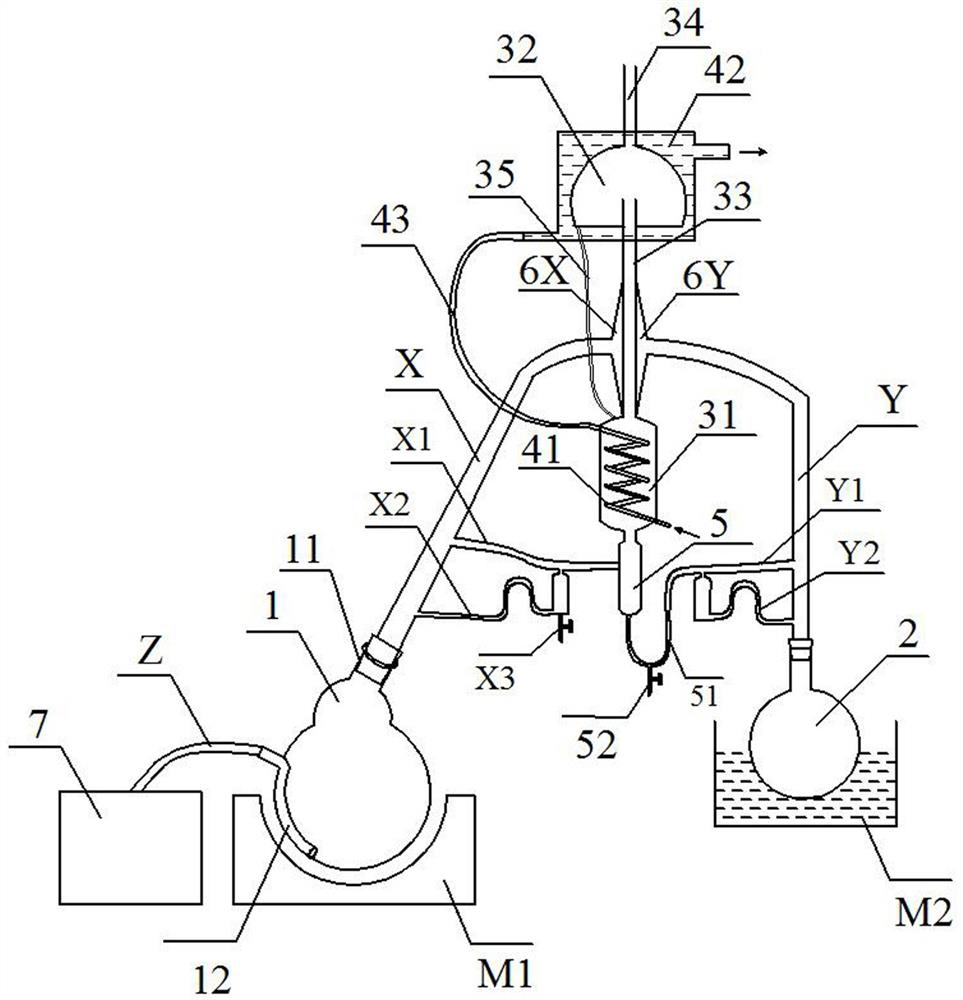

[0040] The present invention has designed a kind of simultaneous distillation extraction device ( figure 1 ), including not only the distillation bottle 1, the solvent bottle 2, the heating device, the condensing system and connecting pipelines in the prior art, but also the steam mixing system.

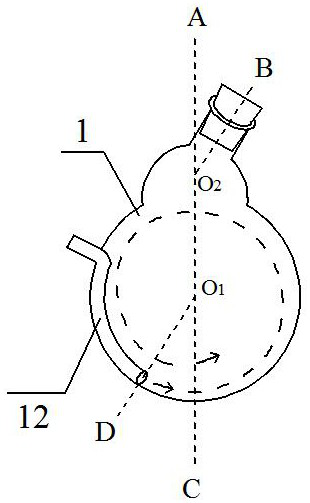

[0041] Different from the prior art, the retort 1 designed by the present invention is gourd-shaped, the upper part is a small sphere, and the lower part is a large sphere. The top of the distillation bottle 1 is provided with a steam outlet 11, and the steam outlet is positioned at the top right of the gourd (that is, the small sphere on the top, such as figure 1 position shown), and with the longitudinal centerline of the hoist (AC, see image 3 ) (ie ∠AO 2 B) is 30-60 °, preferably 45 °; the bottom of the distillation bottle 1 (that is, the large sphere at the bottom, such as figure 1 The position shown) is provided with a steam inlet pipe 12 on the inner wall; steam enters the...

Embodiment 2

[0049] 1 Materials and methods

[0050] 1.1 Test material

[0051] In July 2020, bamboo leaves of yellow sweet bamboo were collected in Lishui, Zhejiang Province, washed and dried naturally in the shade, then dried in an oven at 40°C for 5 hours, crushed with a pulverizer, passed through a 40-mesh sieve, and then stored at -40°C in the fridge.

[0052] 1.2 Extraction of essential oil from bamboo leaves

[0053] In this experiment, the extraction of bamboo leaf volatile oil was carried out according to the experimental design in Table 1. The part of this experiment without special instructions was carried out according to the method of the prior art.

[0054] There are three types of devices involved: device one is the device in Example 1; device two is device one without the steam generating device and connecting pipe (that is, the steam inlet pipe of the retort is not connected to the steam generating device), and the steam inlet is closed with a plug. The inlet end of th...

Embodiment 3

[0076] In order to take into account the yield and quality of the volatile oil, this embodiment is used in the device designed in Example 1 according to the following method: the steam generating device is connected to the steam inlet pipe through the connecting pipe; the heating device and the steam generating device are turned on to make the distillation The liquid in the bottle is slowly heated to a slightly boiling state and kept in a slightly boiling state for 1 hour (the device and method are similar to the sample number A1-1 in Example 2); then turn off the steam generating device and only use the electric heating mantle to heat, and then turn on the distillation reflux Valve X3 and collection valve 52 (here is different from sample number A1-1 in embodiment 2), respectively place receiving bottle under distillation reflux valve X3 and collection valve 52, respectively receive the water phase and organic solvent phase of distillation reflux, until The liquid in the disti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com