Efficient dust removal and heat preservation type circulating stirring-cage-free grain drying machine

A grain dryer and heat preservation technology, applied in grain drying, non-progressive dryers, dryers, etc., can solve the problems of clogged granaries and blockages, and achieve the effects of avoiding damage, expanding the area, and promoting the effect of tumbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

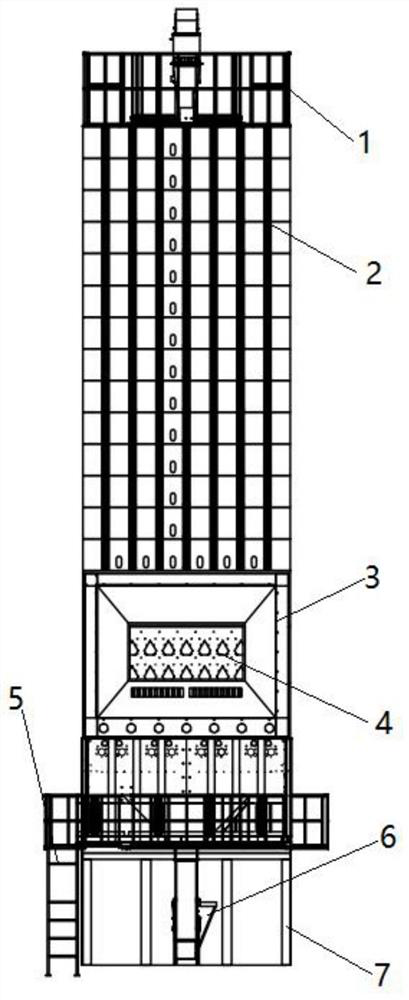

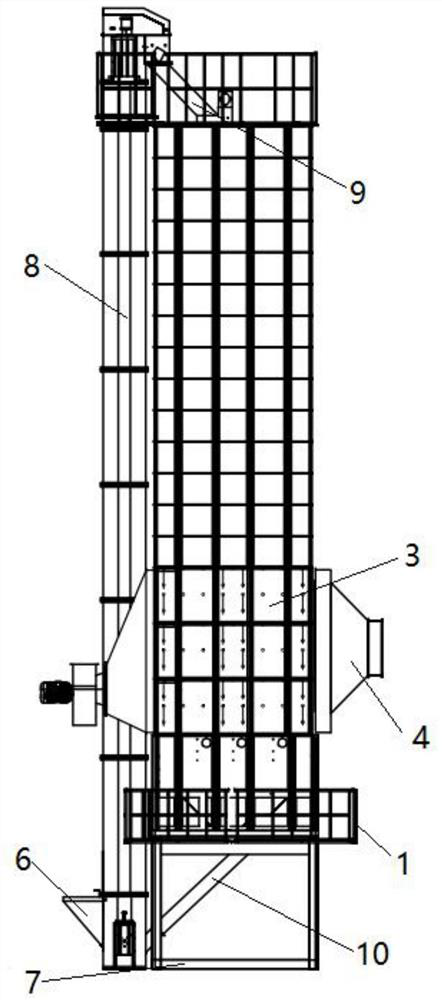

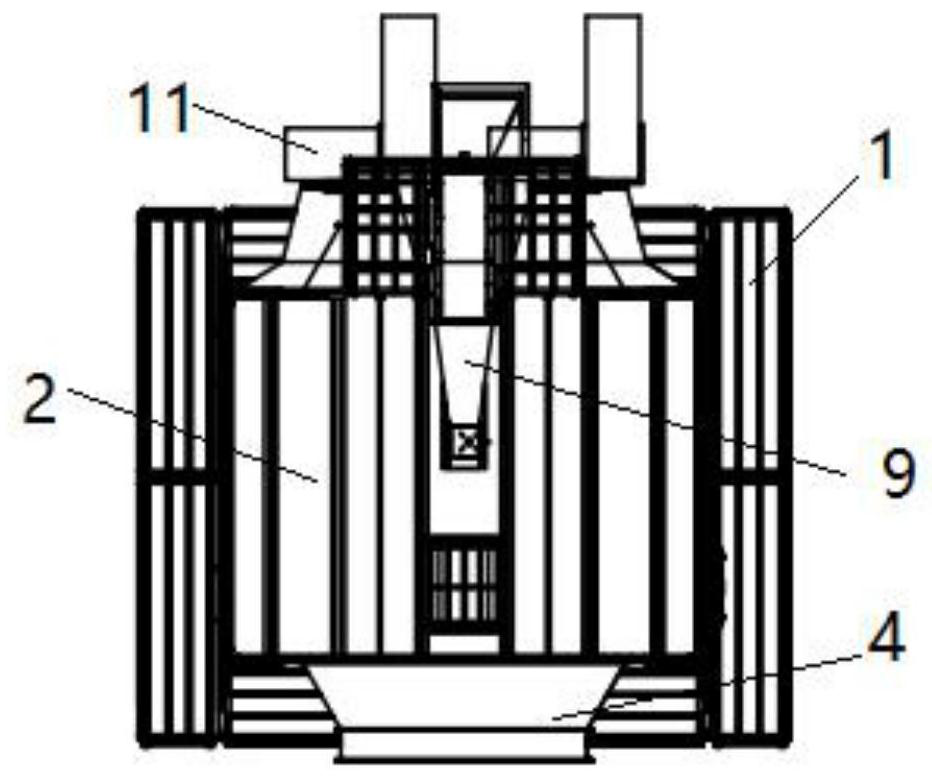

[0033] A high-efficiency dust-removing and heat-retaining circulating non-stirring cage grain dryer, such as Figure 1-5 As shown, it includes a storage bin 2, a drying bin 3 and four pillars 7. The tops of the four pillars 7 are fixed with a hopper 12 through threads, and one side of the outer wall of the hopper 12 is threaded with a second threaded connection. Two guide pipes 10, the top outer wall of the discharge hopper 12 is fixed with a mounting plate by bolts, and the surrounding outer walls of the mounting plate are fixed with brackets 1 by bolts, and the top outer wall of the mounting plate is connected with the bottom of the drying bin 3 by bolts. The top outer wall of the drying bin 3 is connected with the bottom of the grain storage bin 2 by bolts, the outer walls on one side of the four pillars 7 are fixed with a hoist 8 by bolts, and the outer walls on both sides of the hoist 8 are connected with a fixed frame 11 by bolts, and One side of the outer wall of the fi...

Embodiment 2

[0041] A high-efficiency dust-removing and heat-retaining circulating non-stirring cage grain dryer, such as Figure 6 As shown, in order to avoid the problem of side leakage when grain passes through the guide hole 19; this embodiment makes the following improvements on the basis of embodiment 1: the outer wall of the top of the drying box 23 is screwed with a snap ring 28, And the top of snap ring 28 is welded with arc-shaped convex plate 29, and the joints of snap-fit ring 28, arc-shaped convex plate 29 and drying box 23 have the same feeding hole respectively, and the outer walls of both sides of drying box 23 A filter screen 27 is provided respectively, a guide hole 31 is opened on the bottom outer wall of the drying box 23, a material trough 30 is arranged inside the drying box 23, and the internal structure of the drying box 23 is an arc-shaped surface structure.

[0042] When the arc-shaped convex plate 29 rotates to the bottom of the guide hole 19, the arc-shaped co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com