A dyeing machine auxiliary agent intelligent distribution system and its control method

A technology for dyeing machines and auxiliaries, applied in the directions of adaptive control, general control system, control/regulation system, etc., can solve the problems of violent flowmeter beat, large measurement error, fluctuation of flowmeter measurement value, etc., to reduce waiting time , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

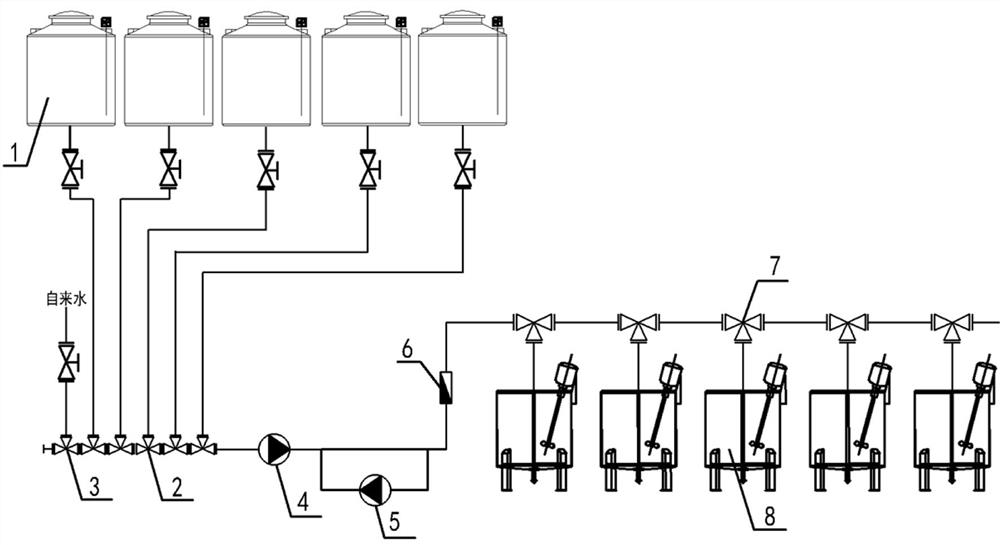

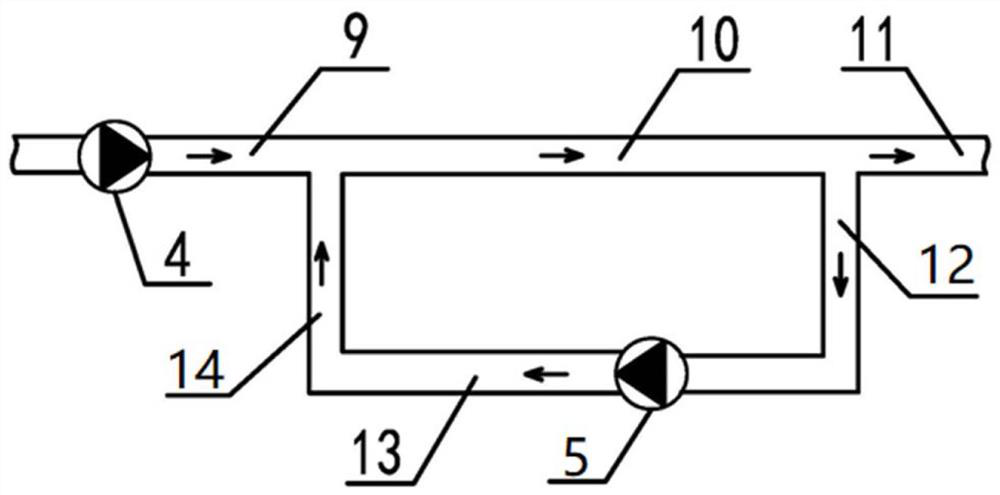

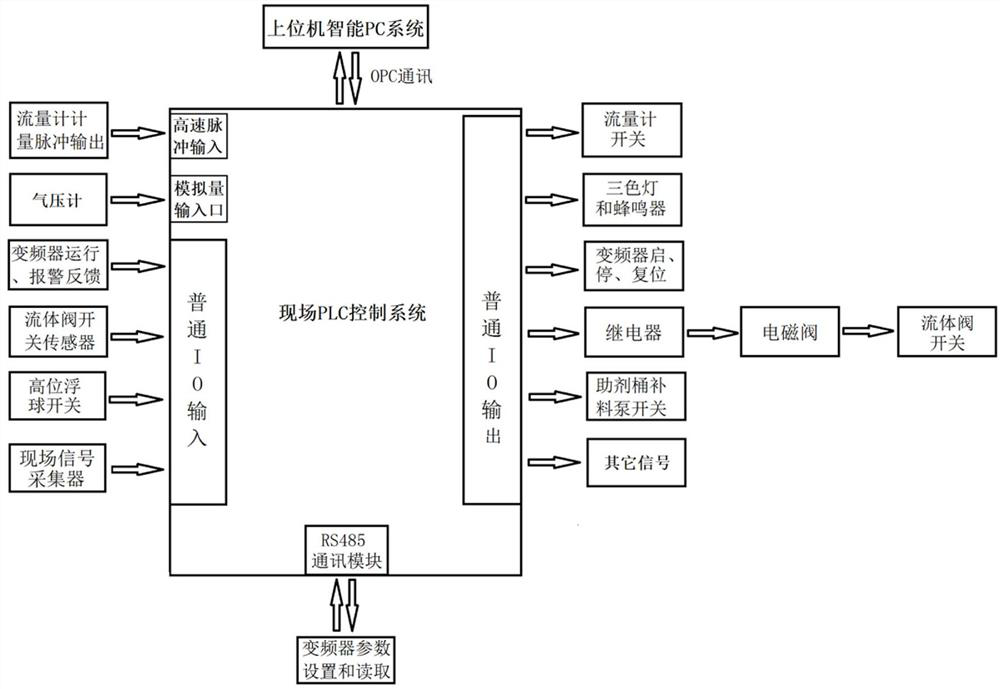

[0060] Such as figure 1 As shown, this embodiment provides a dyeing machine auxiliary agent intelligent distribution system, including: auxiliary agent storage tank 1, auxiliary agent distribution valve 2, flushing water valve 3, distribution rotor pump 4, pipeline reverse forced mixer, flow meter 6. Blanking valve 7, material tank 8 of dyeing machine and control system;

[0061] The auxiliary agent storage tank 1 is connected with the auxiliary agent distribution valve 2, the auxiliary agent distribution valve 2 is connected with the distribution rotor pump 4, the distribution rotor pump 4 is connected with the flow meter 6, the flow meter 6 is connected with the discharge valve 7, and the discharge valve 7 is connected with the Dyeing machine material tank 8 is set correspondingly, flushing water valve 3 is connected with auxiliary agent distribution valve 2, and reverse mixing pump 5 is installed in the pipeline reverse forced mixer;

[0062] Among them, the auxiliary age...

Embodiment 2

[0107] Such as Figure 5 As shown, this embodiment provides a control method for a dyeing machine auxiliary agent intelligent distribution system, including the following steps:

[0108] Step1: The upper computer intelligent PC system reads the auxiliary agent name, dosage and dyeing machine tank number of the auxiliary agent delivery order from the ERP system, reads the control instruction information of the auxiliary agent delivery order from the dyeing machine central control, and sends it to the PLC after comprehensive processing The control system issues an order for the distribution of additives;

[0109] Step2: The PLC control system receives the auxiliary agent distribution order, opens the corresponding auxiliary agent distribution valve according to the auxiliary agent number, opens the corresponding blanking valve according to the material vat number of the dyeing machine, and starts the frequency converter at the same time to control the rotation of the rotor pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com