Chip weakening structure and manufacturing method thereof, mass transfer method, display panel

A manufacturing method and chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of low transfer efficiency of a large amount of Micro-LED chips, and achieve the effect of improving transfer accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

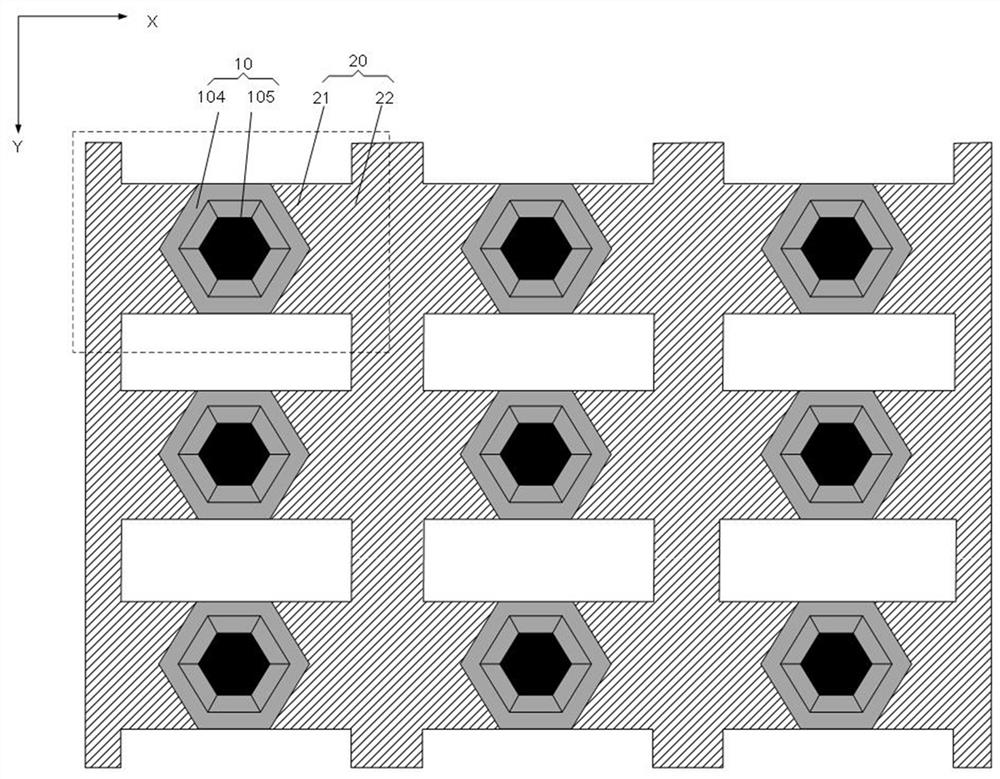

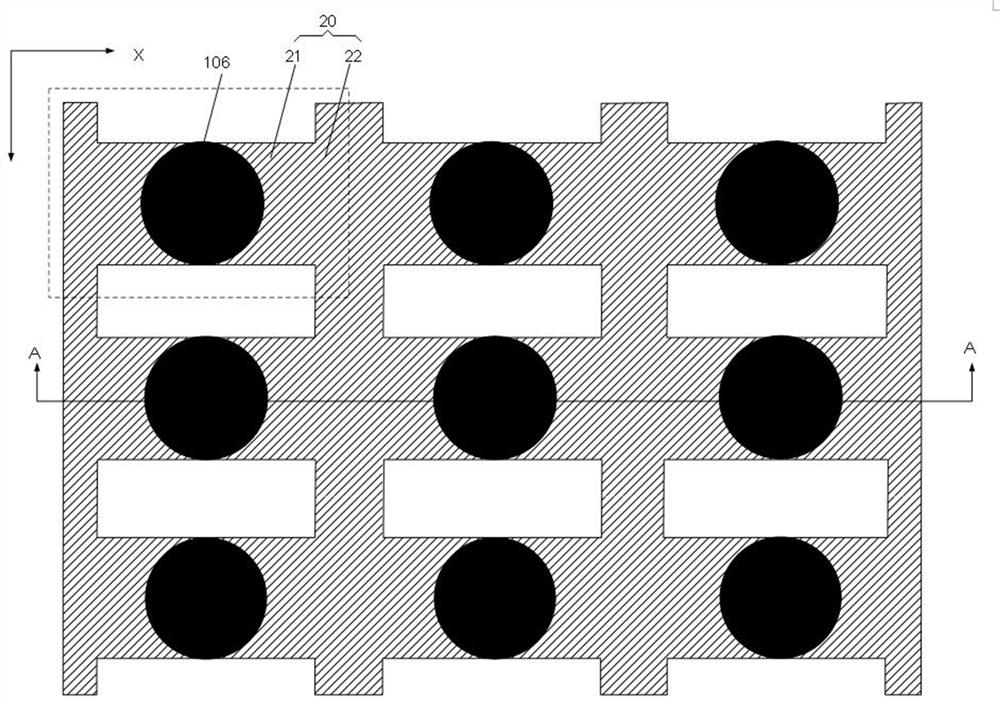

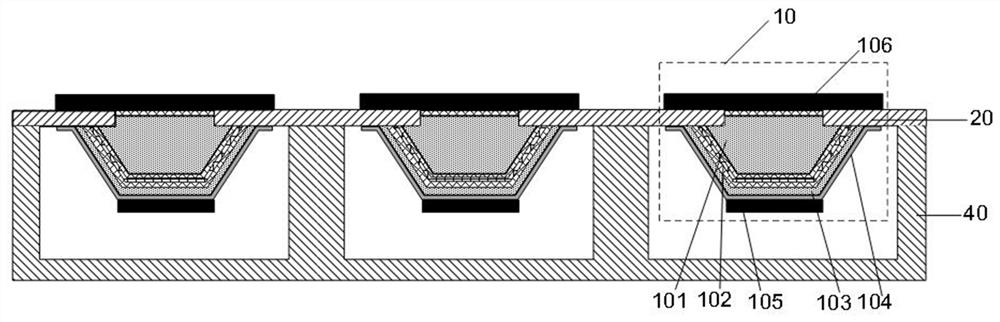

[0080] As mentioned in the background technology section, mass transfer is the core technical problem faced in the process of Micro-LED industrialization at present. Micro-LED chips must first be bonded to substrates made of silicon or sapphire during the manufacturing process, and then peeled off by laser. The silicon or sapphire substrate is removed, and then the Micro-LED chip is transferred onto the driving circuit substrate. In the process of mass transfer, after the silicon or sapphire substrate is removed by laser lift-off, the Micro-LED chip will fall off from the substrate, and multiple independent single LED chips will be formed, which are randomly arranged and their positions are not fixed, resulting in During the mass transfer process, it is difficult to position a single Micro-LED chip when clamping or adsorbing, and when transferring to the drive circuit substrate, the position of the Micro-LED chip is difficult to control, resulting in a cumbersome and time-consu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com