Precast concrete pile mechanical connector

A prefabricated concrete and mechanical joint technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of ineffective welding quality, low construction efficiency, environmental pollution, etc., to facilitate rapid construction and ensure engineering The effect of progress and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

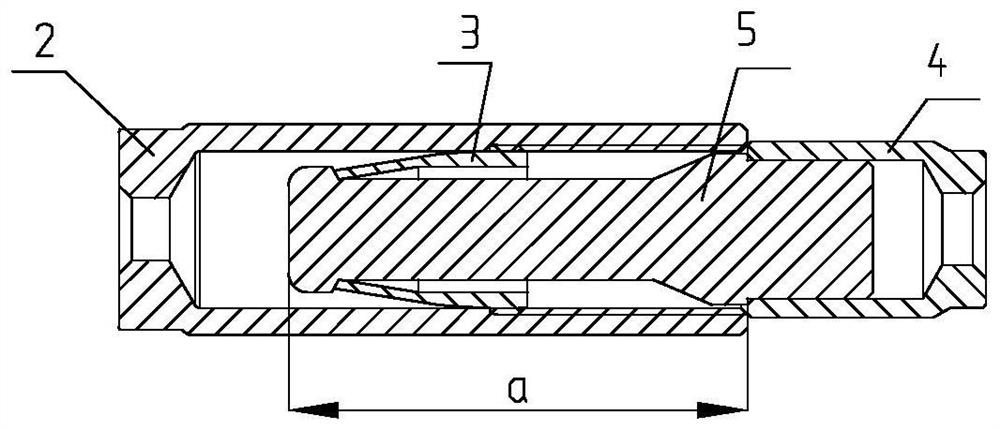

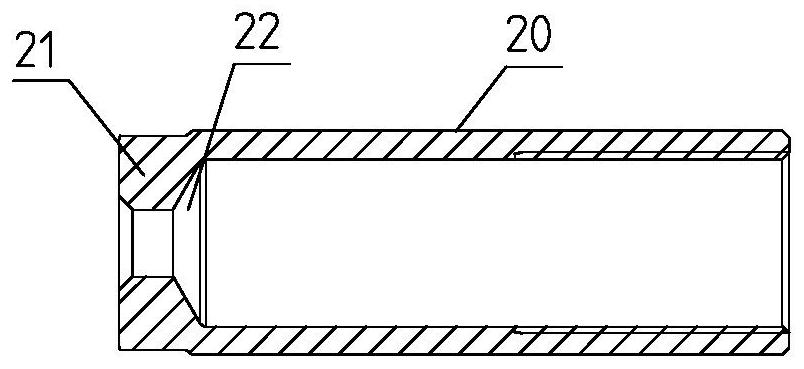

[0038] Such as Figure 1 to Figure 7 Shown is the precast concrete pile mechanical joint disclosed by the present invention, including connecting pipe 2, clamping member 3, inserting rod 5 and tensioning sleeve 4; as image 3 As shown, the connecting pipe 2 includes a connecting pipe main body 20 and a first main rib connecting portion 21 for connecting with the main rib 11, the first main rib connecting portion 21 is a radially inward flange, and the flange can The header 12 of the main rib 11 is limited in the connecting pipe main body 20; the connecting pipe main body 20 is provided with the clamping member 3; as Figure 4 As shown, the tensioning sleeve 4 includes a sleeve main body 40 and a second main rib connecting portion 41 for connecting with the main rib 11, the second main rib connecting portion 41 is a radially inward flange, and the protruding The edge can limit the heading head 12 of the main rib 11 in the sleeve main body 40; as Figure 5 As shown, the insert...

Embodiment 2

[0049] Such as Figure 8 to Figure 14 Shown is the first embodiment of the precast concrete pile with the mechanical joint of the precast concrete pile disclosed in the present invention, the precast concrete pile is a pipe pile, including a pile body 10, and one end of the main reinforcement 11 of the precast concrete pile is connected with the connecting pipe 2 , the other end is connected to the tensioning sleeve 4, the connecting pipe 2 is arranged in the pile body 10 and the end port of the connecting pipe 2 away from the main reinforcement 11 faces the outside of the end surface of the pile body 10, and the connecting pipe 2 is provided with a clamp Firmware 3, the tension sleeve 4 is arranged in the pile body 10 and the end port of the tension sleeve 4 away from the main reinforcement 11 faces the outside of the end face of the pile body 10, as Figure 11 As shown, the tensioning sleeve 4 is a sleeve structure, and one end is a radially inward flange forming a second ma...

Embodiment 3

[0069] Such as Figure 15 to Figure 21Shown is the second embodiment of the precast concrete pile with the mechanical joint of the precast concrete pile disclosed in the present invention. The difference between this implementation and Embodiment 2 is that the precast concrete pile in Embodiment 2 is a pipe pile. The concrete pile is a square pile, including a pile body 10. One end of the main reinforcement 11 of the prefabricated concrete pile is connected to the connecting pipe 2, and the other end is connected to the tensioning sleeve 4. The connecting pipe 2 is arranged in the pile body 10 and the The port at one end of the connecting pipe 2 away from the main reinforcement 11 is facing the outside of the end surface of the pile body 10. The connecting pipe 2 is provided with a clamping member 3, the tensioning sleeve 4 is arranged in the pile body 10 and the tensioning sleeve 4 is away from the pile body. One end port of the main reinforcement 11 faces the outside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com