Fairing and production method thereof

A technology of shroud and side plate, applied in the field of shroud and its production, which can solve the problems of high cost of 1.5mm stainless steel material, great impact on health and working environment, harsh and sharp beating noise, etc., and reduce outsourcing process Cost, comprehensive cost reduction, and the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

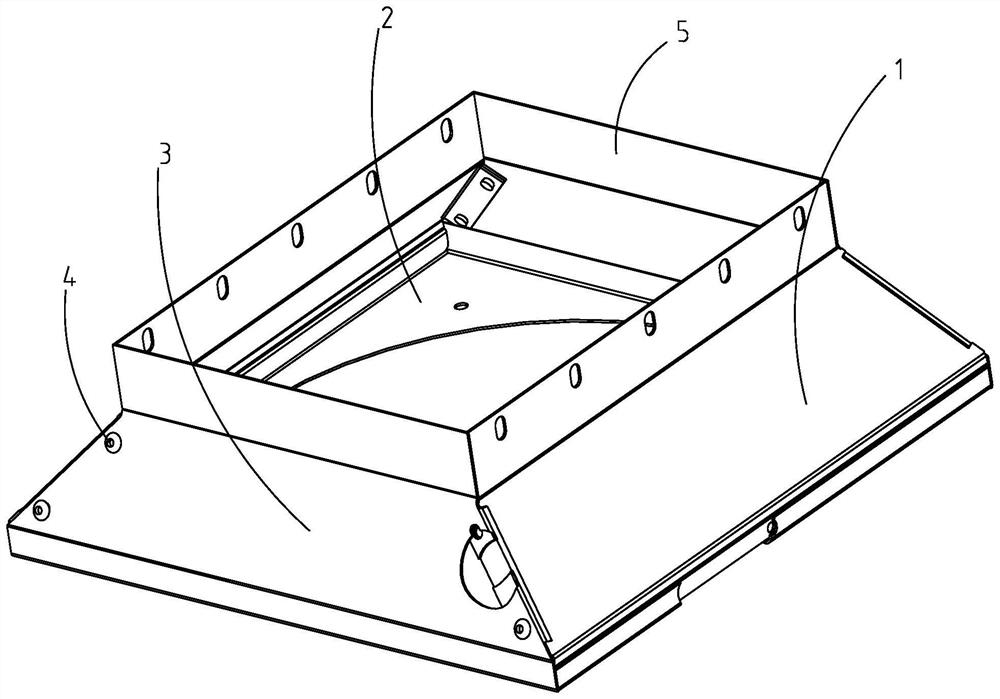

[0037] Such as figure 1 , 2 , 3, a wind deflector, which includes a main frame and two auxiliary side panels 1 symmetrically assembled on the left and right sides of the main frame, the main frame includes a bottom plate 2 and two symmetrically arranged on the front and rear sides of the bottom plate 2 a main side panel 3; wherein,

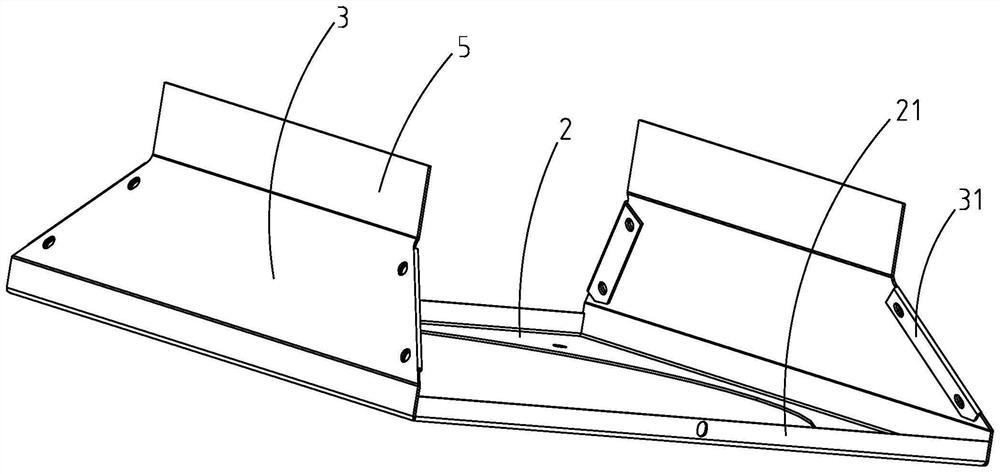

[0038] The bottom end of the bottom plate 2 is open and has an upwardly bent bent edge 21, and the left and right sides of the main side plate 3 are respectively folded inward with flattened edges 31 that fit the main side plate 3 ;

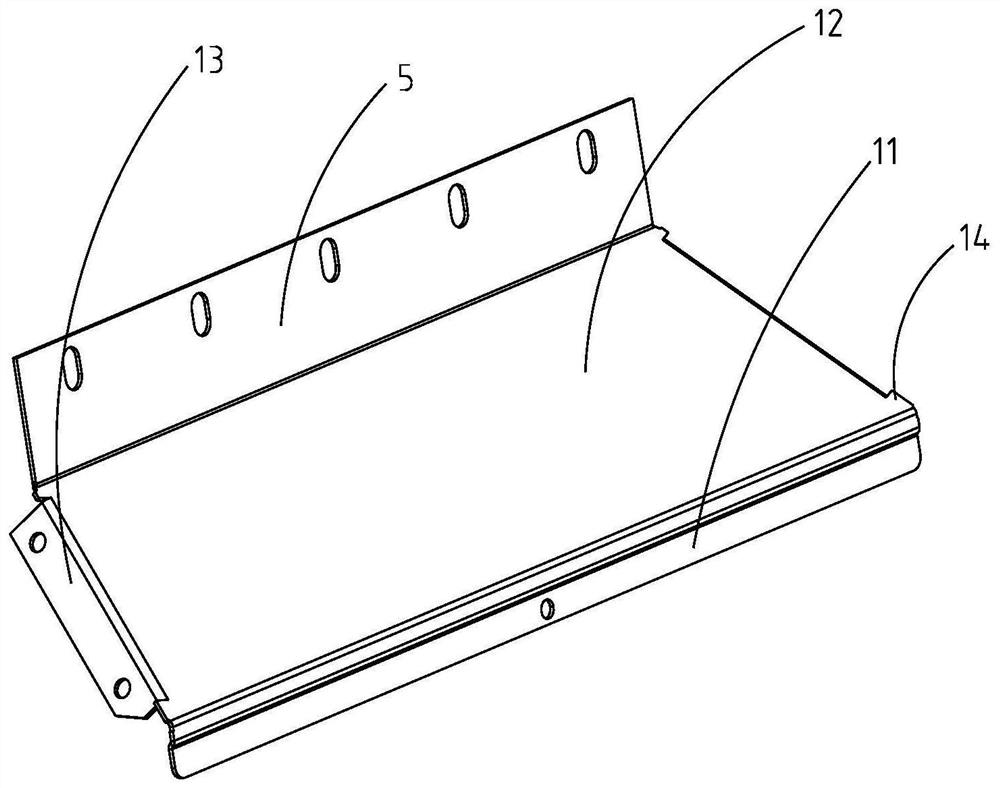

[0039] The auxiliary side plate 1 includes an engaging edge 11 and a side slant plate 12 arranged sequentially from bottom to top, and the front and rear sides of the side slant plate 12 are respectively bent inwardly with wings 13 ;

[0040] The outer surface of the engaging side 11 coincides with the inner surface of the corresponding bending side 21, and the flap 13 coincides with the corresponding flattening s...

Embodiment 2

[0053] Such as figure 1 , 2 , Shown in 3, a kind of production method of shroud as described in embodiment one, comprises in the method step:

[0054] Process the main frame and two side panels 1;

[0055] Insert the auxiliary side plate 1 from the bottom opening of the main frame, rotate and move, so that the engaging side 11 coincides with the corresponding bending side 21, and the flap 13 coincides with the corresponding flattening side 31;

[0056] The overlapping engagement edge 11 and the bending edge 21 and the overlapping tab 13 and the flattening edge 31 are respectively fixedly connected through the connection assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com