MnO2-coated nano-crystal core-shell structure catalyst and preparation method and application thereof

A technology of core-shell structure and catalyst, which is applied in the field of MnO2@nanocrystalline core-shell structure catalyst and its preparation, can solve the problems of reducing the efficiency of catalytic reduction and denitrification, and achieve the effect of regular shape and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

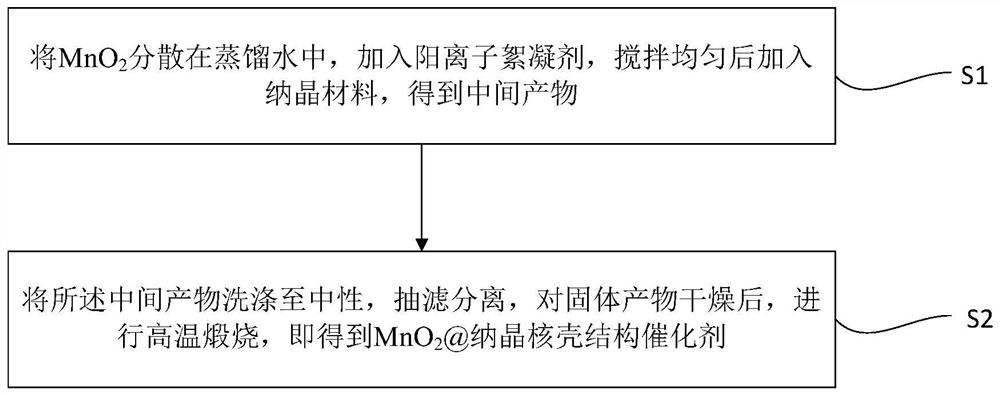

[0028] combine figure 1 shown, a MnO 2 The preparation method of @nanocrystalline core-shell structure catalyst includes the following steps:

[0029] S1, the manganese dioxide MnO 2 Disperse in distilled water, add cationic flocculant, stir evenly and add nanocrystalline material to obtain an intermediate product;

[0030] S2. Wash the intermediate product to neutrality, separate it by suction filtration, dry the solid product, and perform high temperature calcination to ensure that the nanocrystals are firmly attached to obtain MnO 2 @Nanocrystalline core-shell structure catalyst.

[0031] In the embodiment of the present invention, the nanocrystalline material is attached to the MnO 2 MnO formed on the surface 2 @Nanocrystalline core-shell structure, the active metal Mn in NO oxidation reaction is used as the core to make its active site play a catalytic role, and the nanocrystalline material is used as the shell layer to selectively permeate the NO and O required for ...

Example Embodiment

[0054] Example 1

[0055] This embodiment provides a MnO 2 The preparation method of @nanocrystalline core-shell structure catalyst includes the following steps:

[0056] 1) MnO 2 nuclear synthesis

[0057] 3g (NH 4 ) 2 S 2 O 8 and 4gMnSO 4 ·H 2 O was dissolved in deionized water, stirred for 30 min to a homogeneous solution, transferred to a hydrothermal kettle at 90 °C for 24 h, the obtained solution was filtered and washed three times with deionized water, the filter cake was dried at 80 °C overnight, and then dried at 300 °C in air Calcined for 2h to obtain MnO 2 .

[0058] 2) Synthesis of nano-S-1 crystals

[0059] The molar ratio of each substance in the precursor is TPAOH / SiO 2 / H 2 O / C 2 H 5 OH=9:25:480:100, a total of 50g, in which the silicon source is ethyl silicate TEOS, after pre-hydrolysis with stirring at room temperature for 12h, it is transferred to a 100mL hydrothermal kettle, and crystallized at 80°C for 72h; after cooling, the obtained nanocr...

Example Embodiment

[0063] Example 2

[0064] This embodiment provides a MnO 2 The preparation method of @nanocrystalline core-shell structure catalyst includes the following steps:

[0065] 1) MnO 2 nuclear synthesis

[0066] 3g (NH 4 ) 2 S 2 O 8 and 4gMnSO 4 ·H 2 O was dissolved in deionized water, stirred for 30 min to a homogeneous solution, transferred to a hydrothermal kettle at 90 °C for 24 h, the obtained solution was filtered and washed three times with deionized water, the filter cake was dried at 80 °C overnight, and then dried at 300 °C in air Calcined for 2h to obtain MnO 2 .

[0067] 2) Synthesis of nano-S-1 crystals

[0068] The molar ratio of each substance in the precursor is TPAOH / SiO 2 / H 2 O / C 2 H 5 OH=9:25:480:100, a total of 50g, in which the silicon source is ethyl silicate TEOS, after pre-hydrolysis with stirring at room temperature for 12h, it is transferred to a 100mL hydrothermal kettle, and crystallized at 80°C for 72h; after cooling, the obtained nanocr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com