Energy-saving and efficient licker-in cleaning device for textile machinery

A technology for textile machinery and cleaning devices, which is applied in the field of energy-saving and high-efficiency licker-in roller cleaning devices for textile machinery, which can solve the problems of time-consuming, laborious, and low cleaning efficiency, and achieve good results, high cleaning efficiency, and reduced use and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

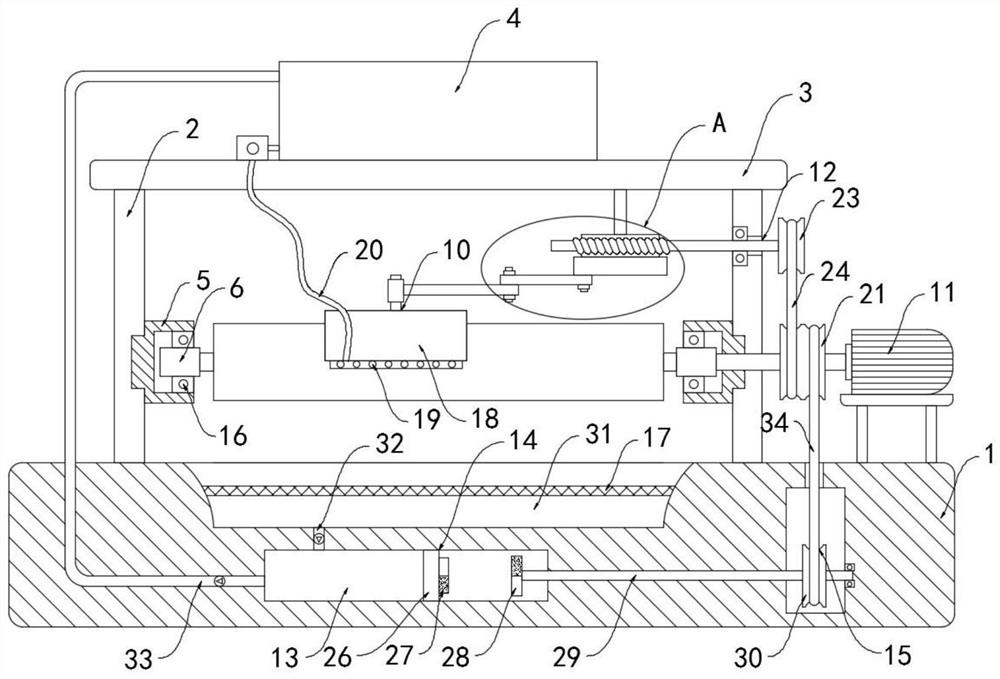

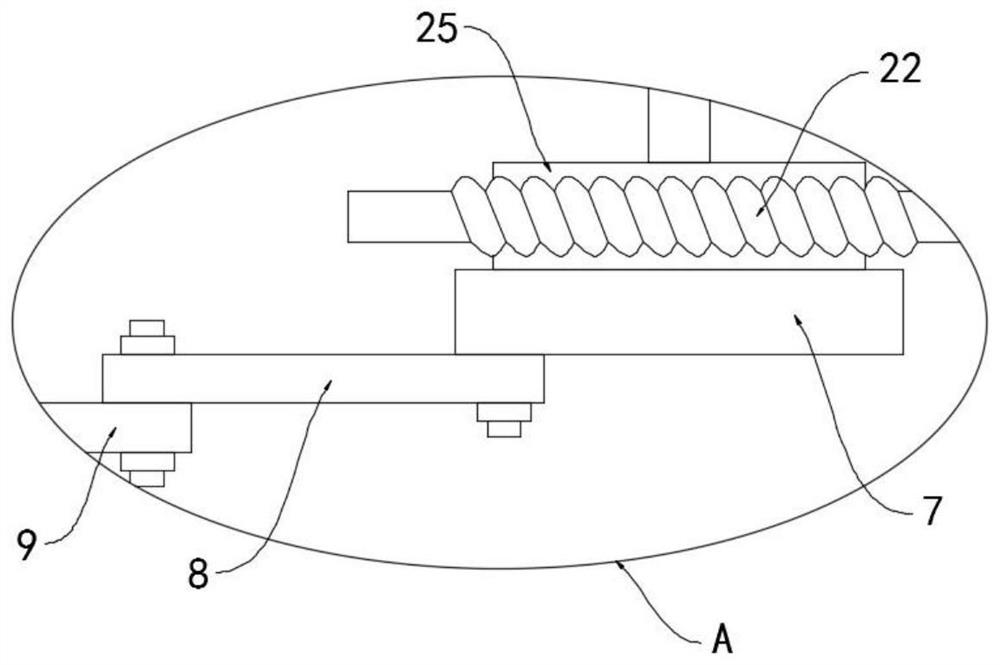

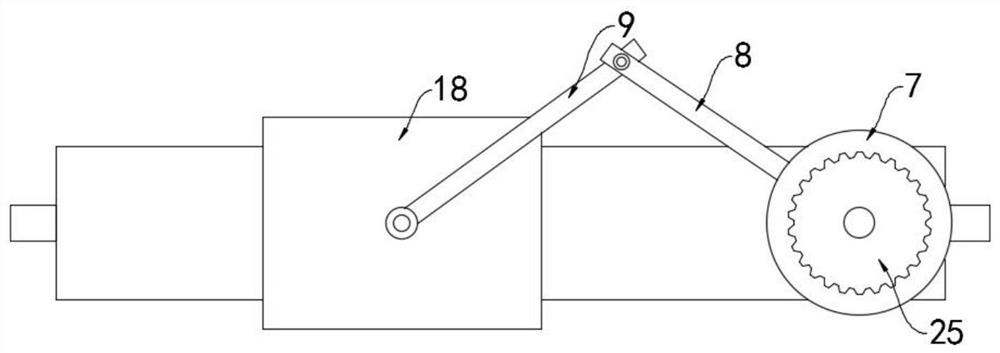

[0029] like Figure 1-5 As shown, an energy-saving and high-efficiency licker-in roller cleaning device for textile machinery includes a base 1 and two side plates 2 fixedly installed on the upper surface of the base 1, the upper ends of the side plates 2 are fixedly connected with a top plate 3, and the upper surface of the top plate 3 A water storage tank 4 is provided, and a rotating seat 5 is installed on the side walls of the two side plates 2 that are close to each other. The rotating seat 5 is rotatably connected with a rotating sleeve 6, and the rotating shafts at both ends of the licker-in roller can extend into the rotating sleeve 6. , when the rotating sleeve 6 rotates, the licker-in roller is driven by friction to rotate. It is worth mentioning that the rotating sleeve 6 is connected to the rotating seat 5 through the rotating bearing 16, and the outer ring of the rotating bearing 16 is fixedly connected to the rotating seat 5. Ring is fixedly connected with rotati...

Embodiment 2

[0038] like Image 6 As shown, the difference between this embodiment and Embodiment 1 lies in that: the arc-shaped brush plate 18 is made of elastic rubber material, and a plurality of magnet blocks 35 are equidistantly embedded in the arc-shaped brush plate 18 .

[0039] In this embodiment, the magnet block 35 can generate a magnetic attraction force to the iron licker-in roller, thereby impelling the arc-shaped brush plate 18 to deform and fit and wrap on the licker-in roller surface, so as to ensure the brushing effect of the arc-shaped brush plate 18 on the licker-in roller, and , The arc-shaped brush plate 18 can change its bending radian according to licker-in rollers of different diameters and sizes, and has a wide range of applications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com