Submersible vehicle laying and recovering device with variable structure and laying and recovering method thereof

A technology for retractable devices and submersibles, which is applied in lifting devices, transportation and packaging, ships, etc., can solve the problems of lack of motion adjustment mechanism, potential safety hazards for large personnel, and inability to meet the needs of submersible retraction, etc., to achieve flexible structure, The effect of high safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

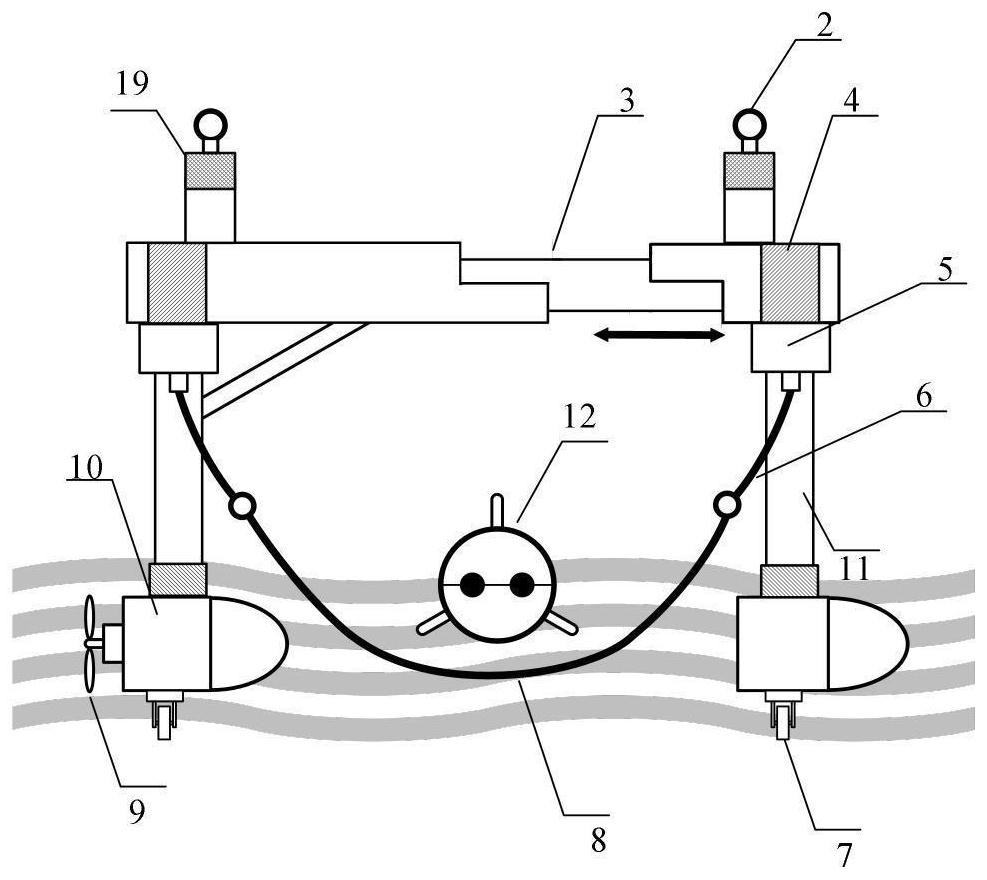

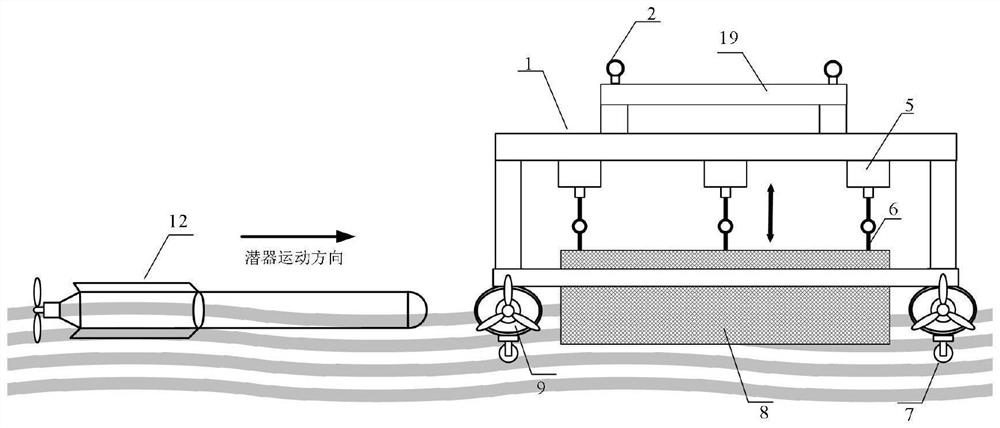

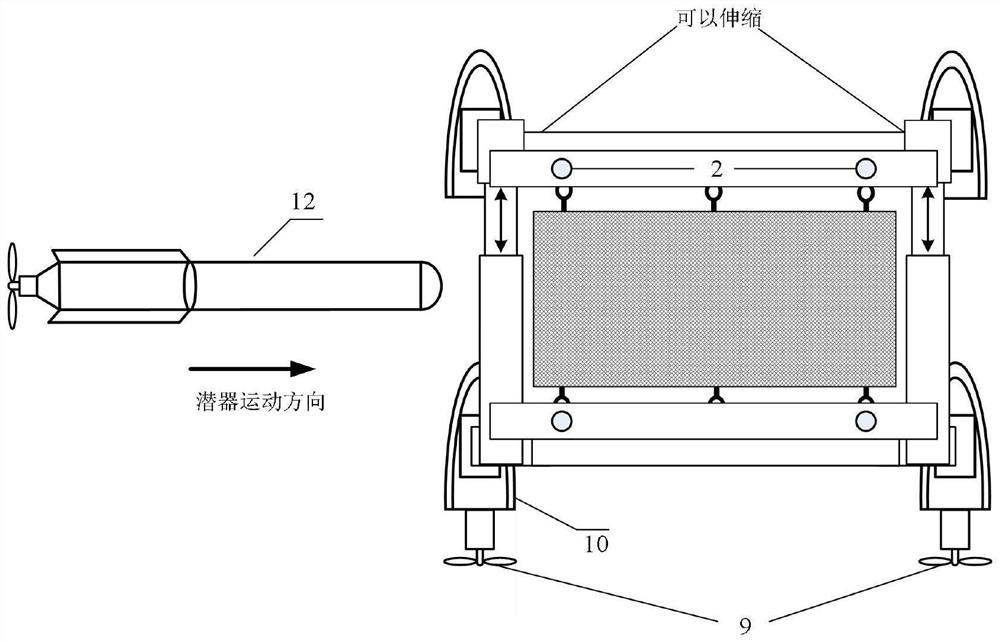

[0039] Such as figure 1 A retractable device with a variable structure is shown, which is used for recovery and deployment of various submersibles in complex sea conditions. 12 is composed of two parts: an electrical control system and a retractable mechanism system. Among them, the electrical control system includes the main control module, electrical drive module, communication module and power supply management module; the retractable mechanism system includes device moving equipment, telescopic equipment and submersible receiving equipment. The mobile equipment is composed of a buoyancy base 1 and a propeller 9; the telescopic equipment is composed of a portal bracket 1, a telescopic mechanism 3, a servo motor and a fixed bracket 6; And load-bearing net 8 constitutes. The upper part of the door-shaped bracket 1 is connected by a telescopic mechanism 3, through which the width of the door-shaped bracket 1 can be changed, winches 5 are installed on the pillars on both sides...

Embodiment 2

[0060] Such as Figure 6 A retractable device with a variable structure is shown, the telescopic equipment and receiving equipment in the electrical control system and the retractable mechanism system of embodiment 2 are exactly the same as those in embodiment 1, and the position and quantity of buoyancy base 1 are also the same as those in embodiment 2. Example 1 remains the same, but propeller 9 is not installed.

[0061] Such as Figure 7 The schematic diagram of the A-frame crane of the mother ship is shown, the A-type 15 frame is equipped with a crane, and the connection between the crane and the A-frame 15 is provided with a horizontal motor 16. The crane can be displaced on the horizontal track 17 by the horizontal motor 16, and its position is adjusted to cooperate with the submersible.

[0062] Such as Figure 8 and Figure 9 The schematic diagram of the hoisting and retracting mechanism shown by the crane adopts the A-frame structure in the invention patent "A Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com