Gas extraction drilling method for intelligent mine and robot system thereof

A robot system and gas drilling technology, applied in directional drilling, drill pipe, drill pipe, etc., can solve the problems of easy changes, hazards, and low precision and efficiency of gas drilling, so as to reduce labor intensity and personnel Quantity, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to understand the technical features, objects, and effects of the present invention, specific embodiments of the present invention will be described with reference to the drawings.

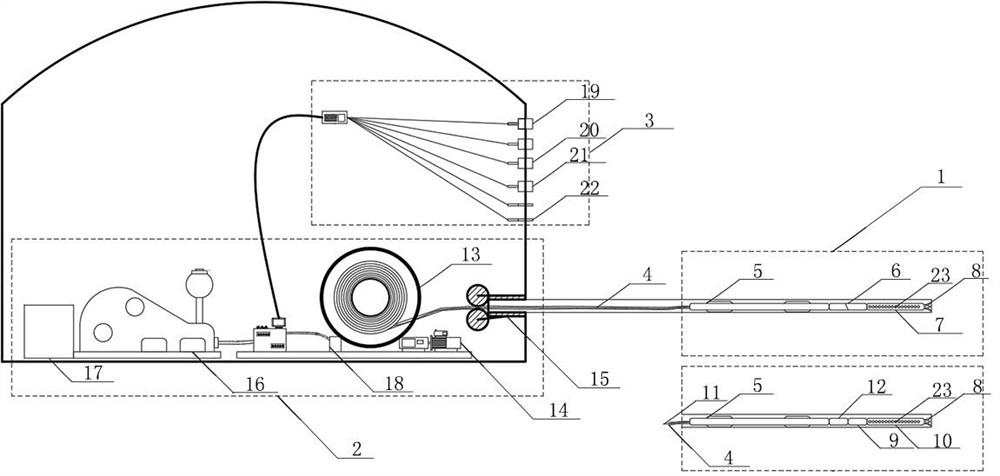

[0026] In this embodiment, if figure 1 Shown, oriented wisdom mine gas drainage drilling robot system, comprising a subsystem drilling, coiled tubing lane roadway 2 and the positioning subsystem 3; lane coiled tubing drilling machine 2, respectively Subsystem 1 and positioning subsystem 3 is connected to the roadway;

[0027] The subsystem 1 comprises a continuous bore tube 4, 5 crawler drill, directed from the orifice to the bottom of the hole 6 in turn connected to the hole bottom and the drill bit 7 drill motor 8; the continuous tube 4 is attached to the cable 11, roadway coiled tubing unit 2 via the cable 11 transmitting power to a drilling subsystem, and achieve bidirectional transmission signal; continuous tube 4 through the tunnel on the injection head 15 and tunnel coiled tubin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com