Overall long anchor cable pre-supporting method for hanging wall broken ore body

A pre-support and long anchor cable technology, which is applied to support the roof beam of the mine roof, mining equipment, earth square drilling and mining, etc., can solve the problems of increasing the amount of steel beams and anchor cables, disturbance of the upper wall ore body, and high construction costs , to achieve the effect of saving mining costs, reducing excavation workload, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

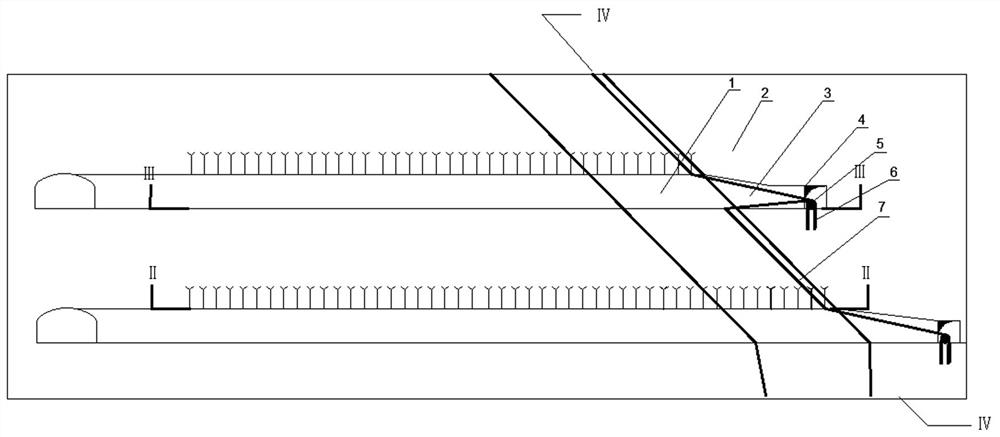

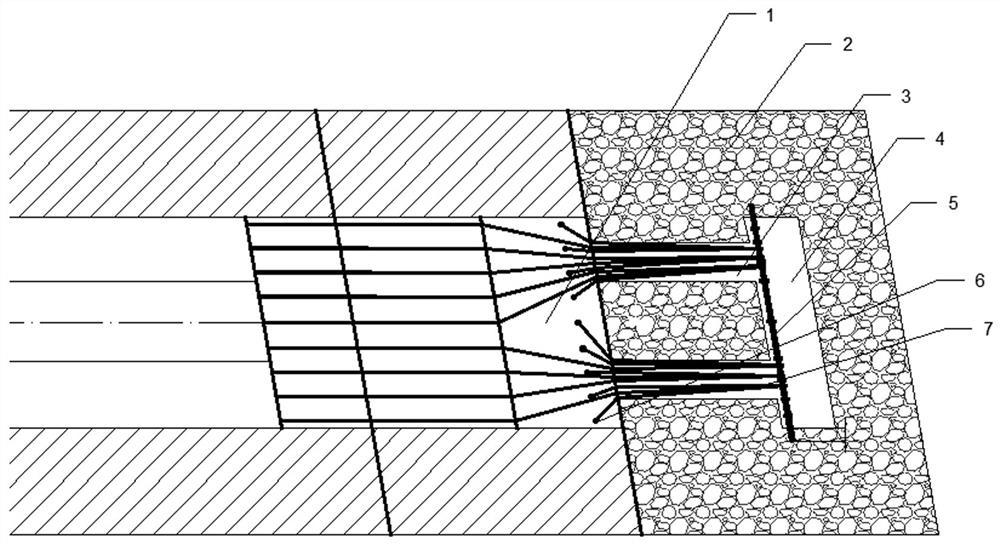

[0033] Such as Figure 1 to Figure 5 As shown, the hanging wall broken ore body long anchor cable pre-support method of the basic embodiment of the present invention comprises the following steps:

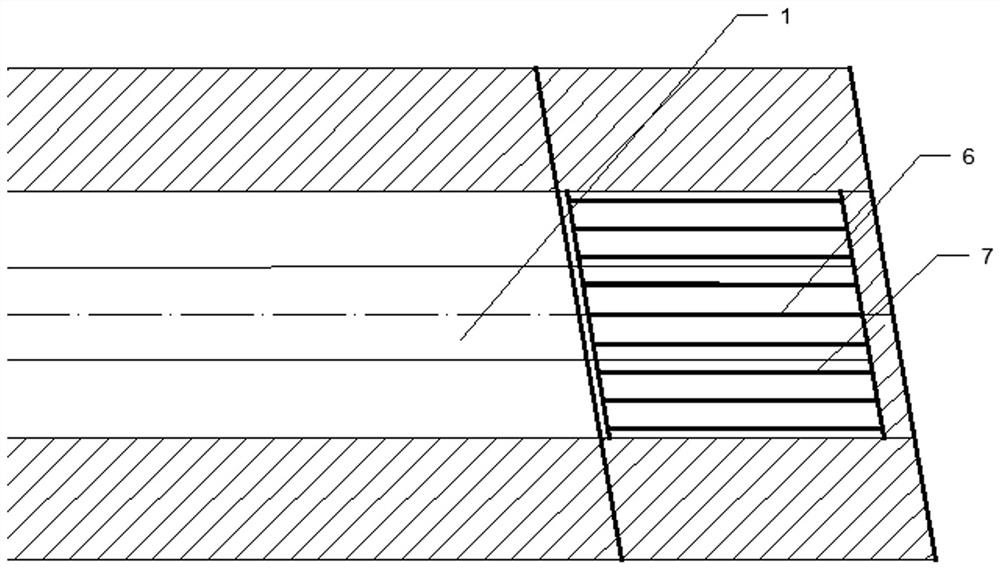

[0034] S1. Excavate two parallel and moderately spaced out-of-vein roadways 3 along the rock-drilling cross roadway 1 at the lower part of the ore body in each segment to excavate the surrounding rock 2 on the broken zone, and pull apart along the ore body direction to form an anchor cable fixed roadway 4 .

[0035] S2. Arrange steel beams 5 in the anchor cable fixing lane 4, the two ends of the steel beams 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com