Novel EGR cooler

An EGR cooler, cooler technology, applied in the direction of machine/engine, engine components, exhaust gas recirculation, etc., can solve the high frequency of EGR valve and cooler failure, affecting the working stability of the engine exhaust after-treatment system, the cooler and the cooler. EGR valve carbon deposition, coking and other problems, to achieve the effect of high precision flow control, strong versatility, and degraded carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

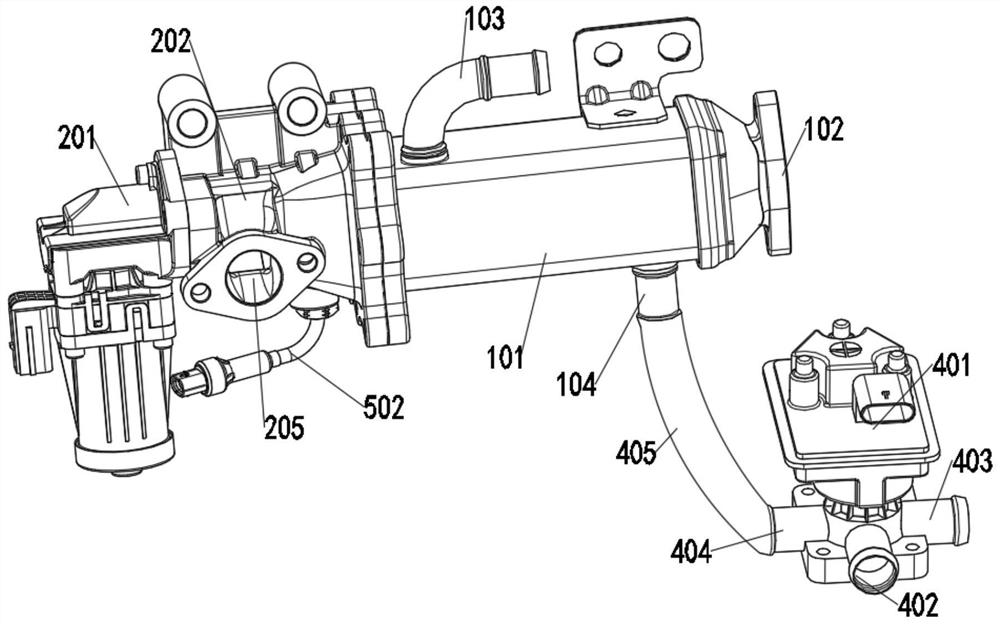

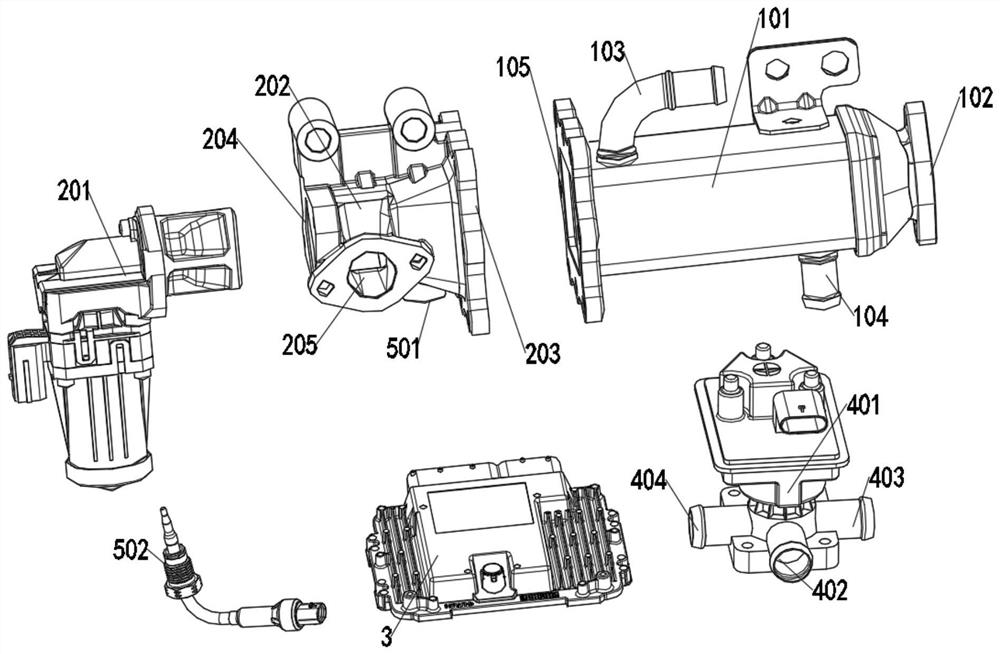

[0025] Such as Figure 1-2 As shown, this embodiment provides a novel EGR cooler, including an EGR cooler assembly, an electric EGR valve assembly, a temperature feedback assembly and a coolant flow adjustment assembly;

[0026] The electric EGR valve assembly includes an EGR valve 201 and a valve seat 202. The valve seat 202 is made of aluminum, which is light in weight and light in weight. Cast aluminum material can be selected to save costs. The valve seat 202 includes a cooler interface 203, a valve body The interface 204 and the exhaust gas outlet interface 205, the valve body 201 is fixed to the valve seat 202 through the valve body interface 204, and the cooler interface 203 and the exhaust gas outlet 105 are fixed by bolts, and the exhaust gas outlet interface 205 communicates with the EGR pipe on the engine, The exhaust gas outlet port 205 is set at the lowest point of the air flow on the valve seat 202, so that the condensed water can be drained, the formation of car...

Embodiment 2

[0040] The coolant flow regulating assembly includes an electronic water pump, a connecting pipe 405 is fixedly connected between the electronic water pump and the liquid inlet pipe 104, and a flow regulating valve controlled by the engine ECU3 is arranged on the electronic water pump.

[0041] The difference from Embodiment 1 is that the electronic water pump is used to control the coolant flow rate of the electronic water pump through the signal sent to the engine ECU3 by the temperature sensor 502 (or the nitrogen oxide content detected by the emission detection system), so as to realize the control of the EGR system. The control of the cooling capacity, when the recirculation exhaust gas temperature is higher than the actual demand temperature, adjust the electronic water pump, increase the coolant flow rate, and enhance its cooling capacity; when the recirculation exhaust gas temperature is lower than the actual demand temperature, adjust the electronic water pump to reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com