Lithium ion cell lamination equipment and process

A lithium-ion and battery technology, applied in the field of lithium-ion battery stacking equipment and stacking technology, can solve the problems of reduced stacking accuracy, equipment cost and efficiency, and low placement efficiency, so as to reduce design complexity, The effect of improving production efficiency and yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

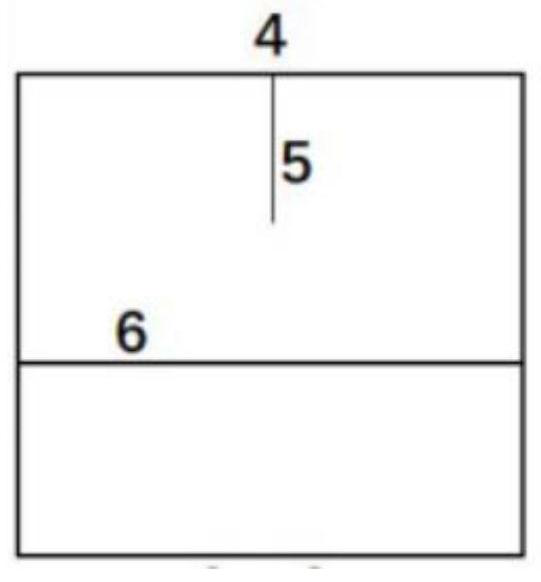

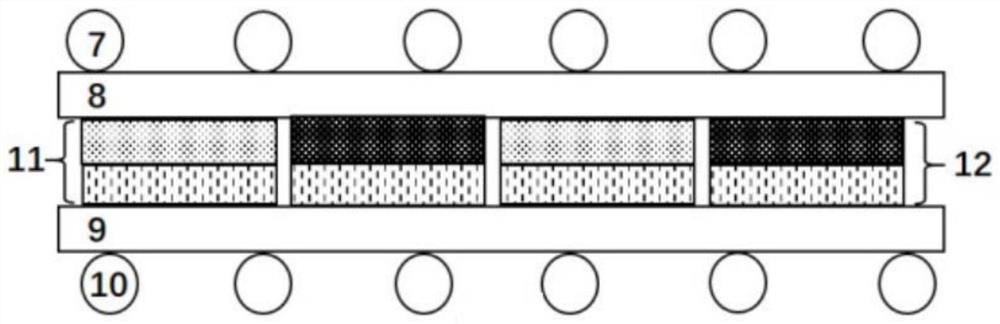

[0036] The invention provides a lithium-ion cell stacking device, which includes a stacking module, a cutting module 4, a transport module, a stacking and bonding module, and a hot-pressing module.

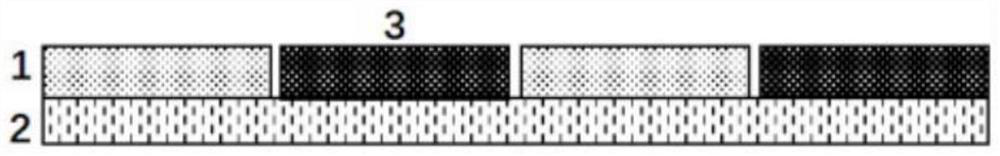

[0037] Specifically, the stacking module arranges the positive electrode sheets 1 and the negative electrode sheets 3 at intervals and heat-presses them on one side of the separator 2 to form a continuous stack, as figure 1 shown. Among them, the positive electrode sheet 1 and the negative electrode sheet 3 are hot-pressed on the diaphragm 2 through a hot-pressing process, the hot-pressing time is 1-100min, the hot-pressing temperature is 60-200°C, and the hot-pressing pressure is 0.1-1000MPa; the diaphragm 2 is treated with a surface coating process , the glue used for surface coating includes polyvinylidene fluoride, polypropylene carbonate, polysiloxane, polyethylene oxide, polyphthalamide, polytrimethylene carbonate, polyvinyl carbonate and polycarbonate One or more of vinyl ...

Embodiment 2

[0043] According to the method of embodiment 1, lithium-ion cell stacking equipment and stacking process are provided, and only the differences are listed below:

[0044] In the stacking module, the positive electrode sheet 1 is hot-pressed on one side of the separator 2, and the negative electrode sheet 3 is hot-pressed on the corresponding position on the other side of the separator 2 to form a continuous stack, such as Figure 6 shown. The unit stack 16 made by the cutting module 4 includes the negative electrode sheet 3, the separator 2 and the positive electrode sheet 1 in order from bottom to top, such as Figure 7 shown. The stacking laminating module arranges the separators 2 and the unit stacks in a stacked form at intervals to obtain neatly arranged multi-layer stacked cells 15 . Specifically, first, as Figure 7 As shown, the lamination unit of the stacking lamination module laminates a diaphragm 2 to the upper surface of the unit stack 16 on the transport module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com