Deflurane evaporation tank with automatic crystal removal structure

A technology of crystalline structure and desflurane, which is applied in the field of desflurane, can solve the problems that the evaporation tank does not have decrystallization, affects the evaporation heat conduction of the evaporation tank, and is prone to crystallization, so as to avoid uneven heating, improve the uniformity of heating, Fully heated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

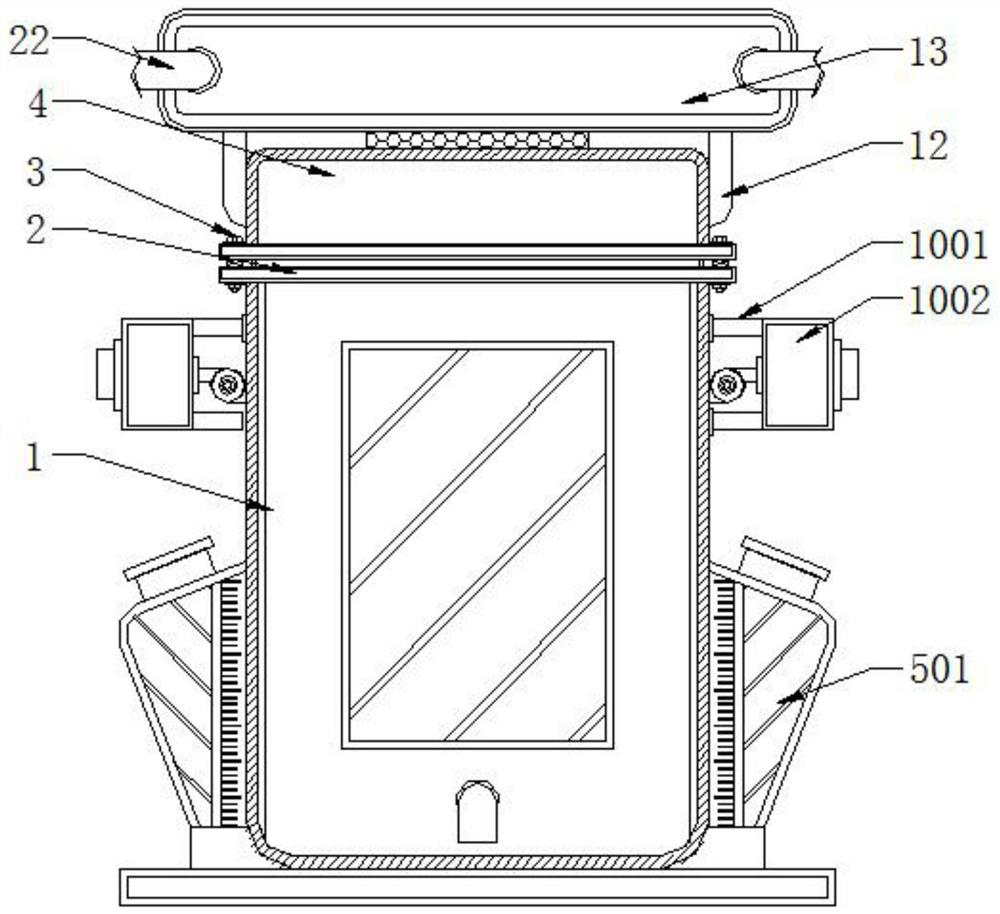

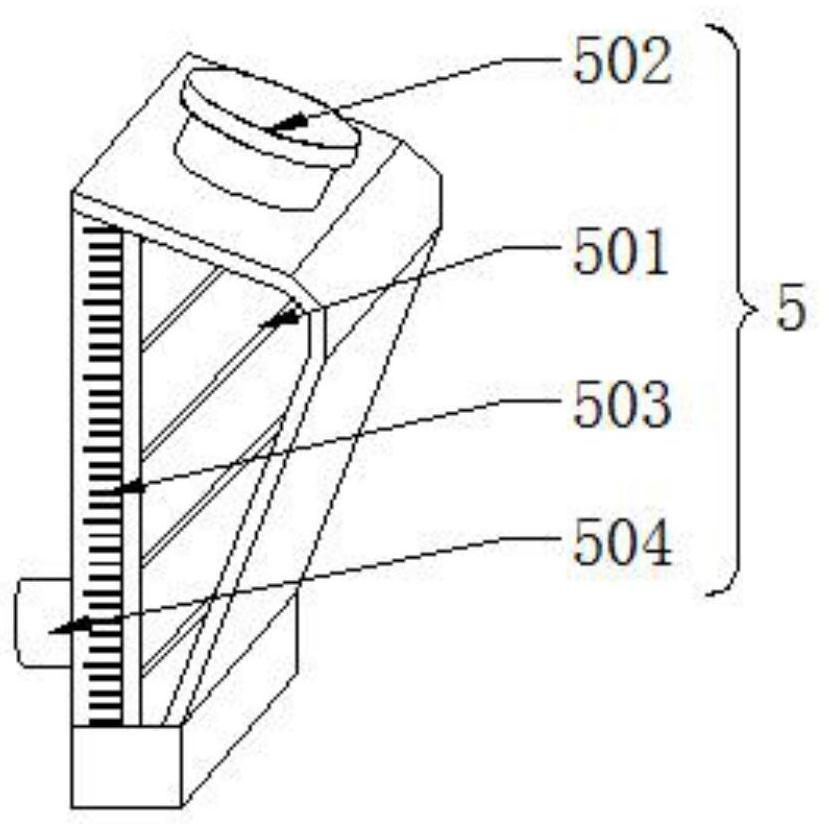

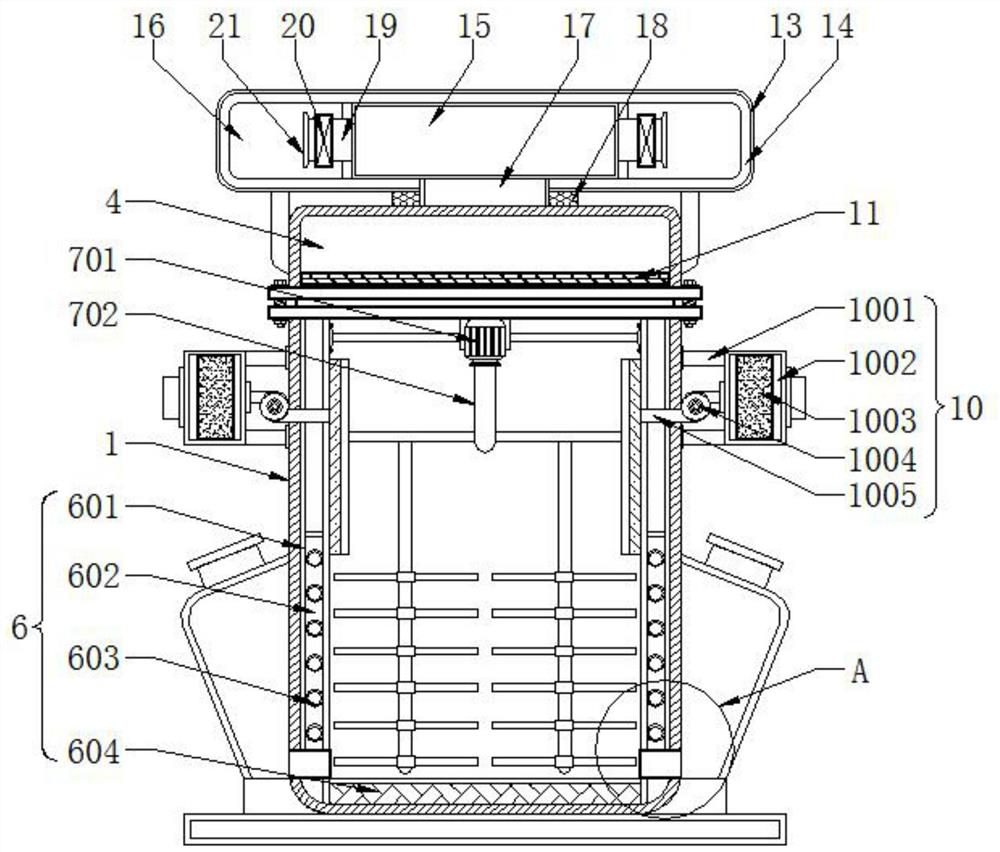

[0030] see Figure 1 to Figure 6The present invention provides a technical solution: a desflurane evaporation tank with an automatic decrystallization structure, including a tank body 1, an evaporation heating component 6 and a decrystallization component 8, and an upper cover 4 is installed on the top of the tank body 1 through a connecting flange 2 , and the outer side of the connecting flange 2 is evenly distributed with locking bolts 3, the tank body 1 is provided with a liquid filling assembly 5 on both sides of the outer lower side, and the evaporation heating assembly 6 is arranged on the inner side of the tank body 1, and the evaporation heating assembly 6 includes There is a vacuum layer 601, a heating layer 602, a heating coil 603 and a heating bottom plate 604. The inner side of the vacuum layer 601 is provided with a heating layer 602, and the inside of the heating layer 602 is provided with a heating coil 603. The inner bottom side of the tank body 1 is fixed Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com