Method for simultaneously extracting multiple active substances in porphyridium

A technology of Porphyra algae and extract, applied in the field of bioengineering, can solve problems such as not mentioned, and achieve the effects of high antioxidant activity, high extraction efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

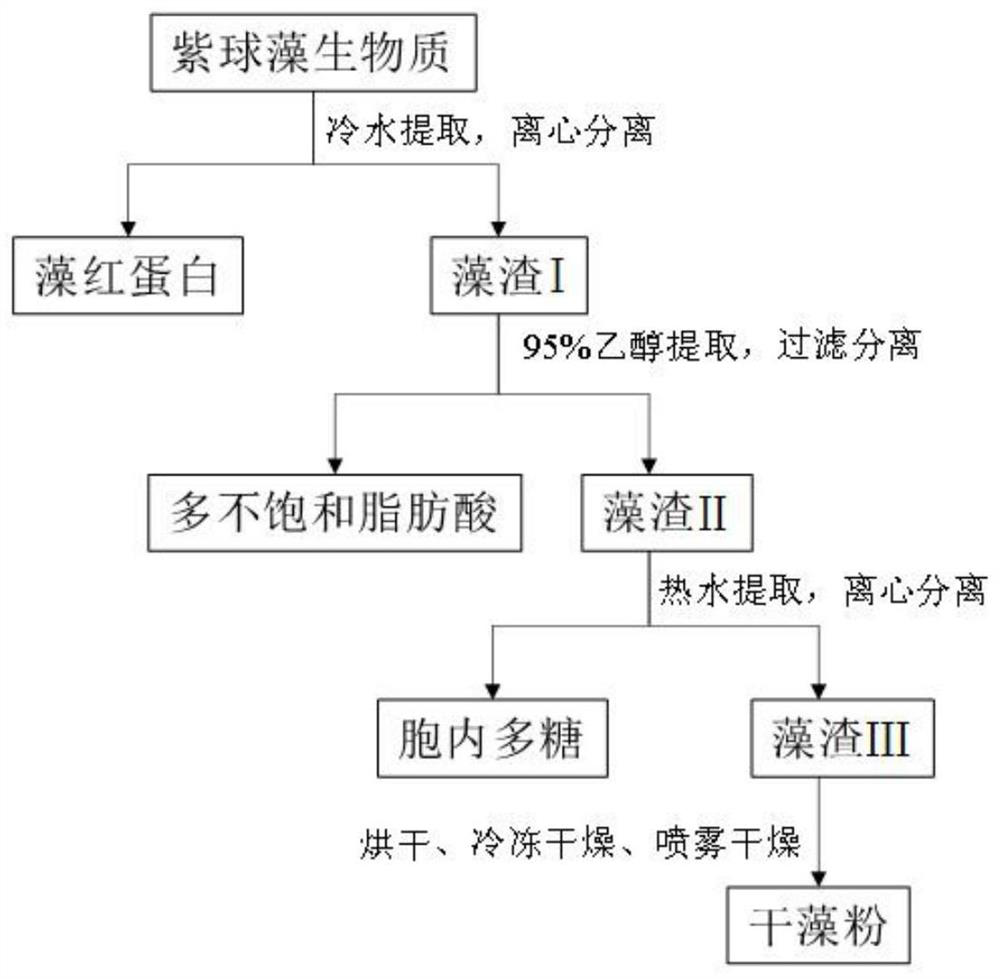

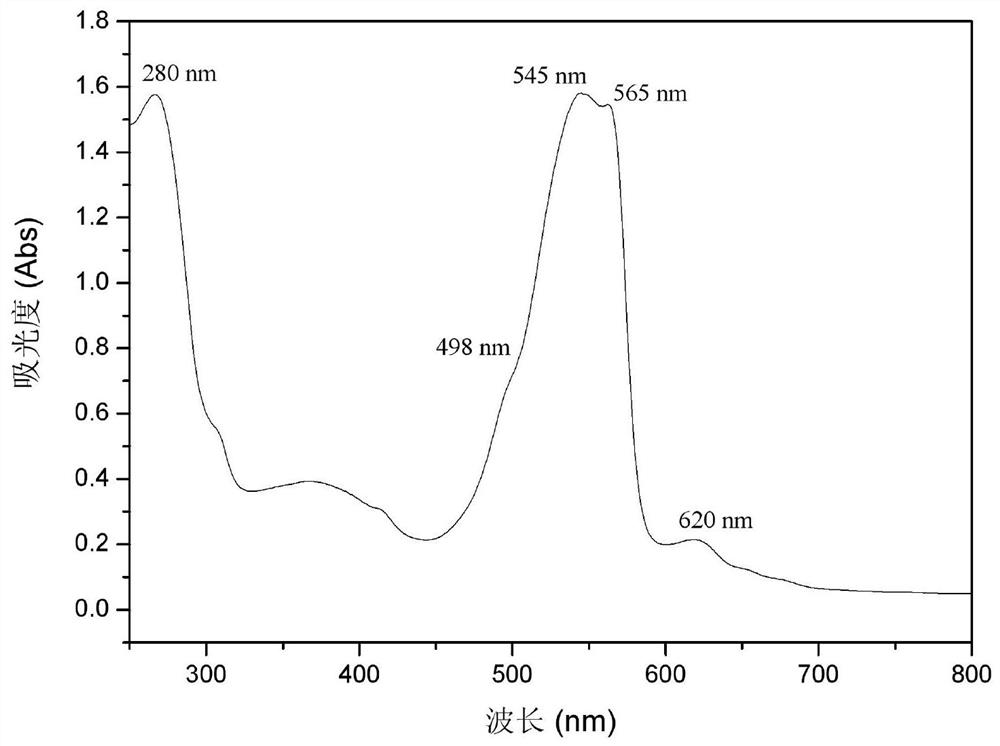

[0030] Embodiment 1 extracts phycoerythrin, polyunsaturated fatty acid and intracellular polysaccharide from Porphyridium algae powder (1.000g)

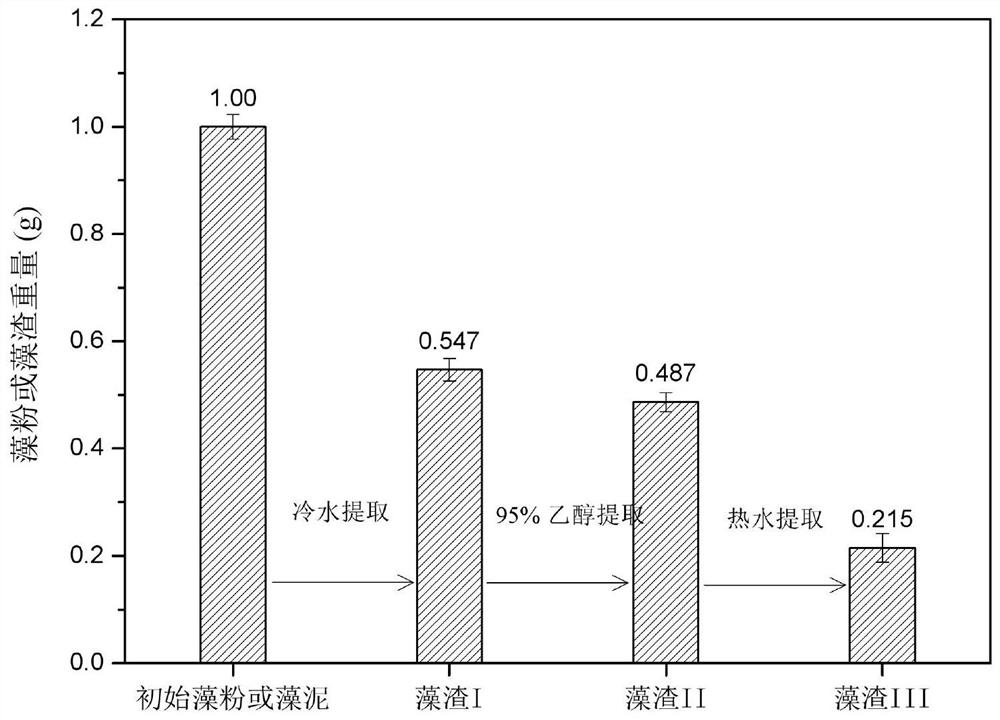

[0031] Extraction process (such as figure 1 (shown): at 4°C, weigh 1.000g of dried Porphyridium algae powder (initial algae powder), add 50mL of 4°C deionized water, stir for 6 hours, centrifuge at 6000 rpm for 5 minutes, and separate the phycoerythrin extract ( cold water extract) and algae residue I. Add 50mL of 95% ethanol aqueous solution by volume fraction to algae residue I, stir for 6 hours, and separate the polyunsaturated fatty acid extract (ethanol extract) and algae residue II by filtering through a membrane with a pore size of 1 micron, and add 50mL of 80°C water to algae residue II again. Deionized water, at 80°C, stir for 2 hours, centrifuge at 6000 rpm for 5 minutes, centrifuge to separate intracellular polysaccharide extract (hot water extract) and algae dregs III, and dry algal dregs III at 80°C .

[0032]Yield an...

Embodiment 2

[0037] Example 2 Phycoerythrin, polyunsaturated fatty acids and intracellular polysaccharides are extracted from Porphyridium algae powder (10.00g)

[0038] Extraction process (such as figure 1 As shown): under the condition of 4°C, weigh 10.00g of dried Porphyridium algae powder (initial algae powder), add 500mL of 4°C deionized water, stir for 6 hours, centrifuge at 6000 rpm for 5 minutes, and separate the phycoerythrin extract ( cold water extract) and algae residue I. Add 500mL of 95% ethanol aqueous solution to the algae residue I, stir for 6 hours, and separate the polyunsaturated fatty acid extract (ethanol extract) and algae residue II by filtering through a membrane with a pore size of 1 micron, and add 500mL of 80°C Deionized water, at 80°C, stir for 2 hours, centrifuge at 6000 rpm for 5 minutes, centrifuge to separate intracellular polysaccharide extract (hot water extract) and algae dregs III, and dry algal dregs III at 80°C .

[0039] Yield analysis: After extr...

Embodiment 3

[0044] Example 3 Phycoerythrin, polyunsaturated fatty acids and intracellular polysaccharides are extracted from Porphyridum algae wet algae mud (100.0g)

[0045] Extraction process (such as figure 1 Shown): At 4°C, weigh 100.0g of Porphyridum wet algae mud (initial algae mud, water content 90.1%), add 400mL of 4°C deionized water, stir for 6 hours, centrifuge at 6000 rpm for 5 minutes, separate Phycoerythrin extract (cold water extract) and algae residue I. Add 400mL of 95% ethanol aqueous solution to the algae residue I, stir for 6 hours, and separate the polyunsaturated fatty acid extract (ethanol extract) and algae residue II by filtering through a membrane with a pore size of 1 micron, and add 400mL of 80°C Deionized water, at 80°C, stir for 2 hours, centrifuge at 6000 rpm for 5 minutes, centrifuge to separate intracellular polysaccharide extract (hot water extract) and algae dregs III, and dry algal dregs III at 80°C .

[0046] Yield analysis: After extraction in cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com