Steam turbine cylinder block casting pouring system and casting process

A pouring system and steam turbine technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of complicated casting operations, difficult to repair castings, and large excavation and repair volume, etc., to improve heat dissipation effect, improve quality, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

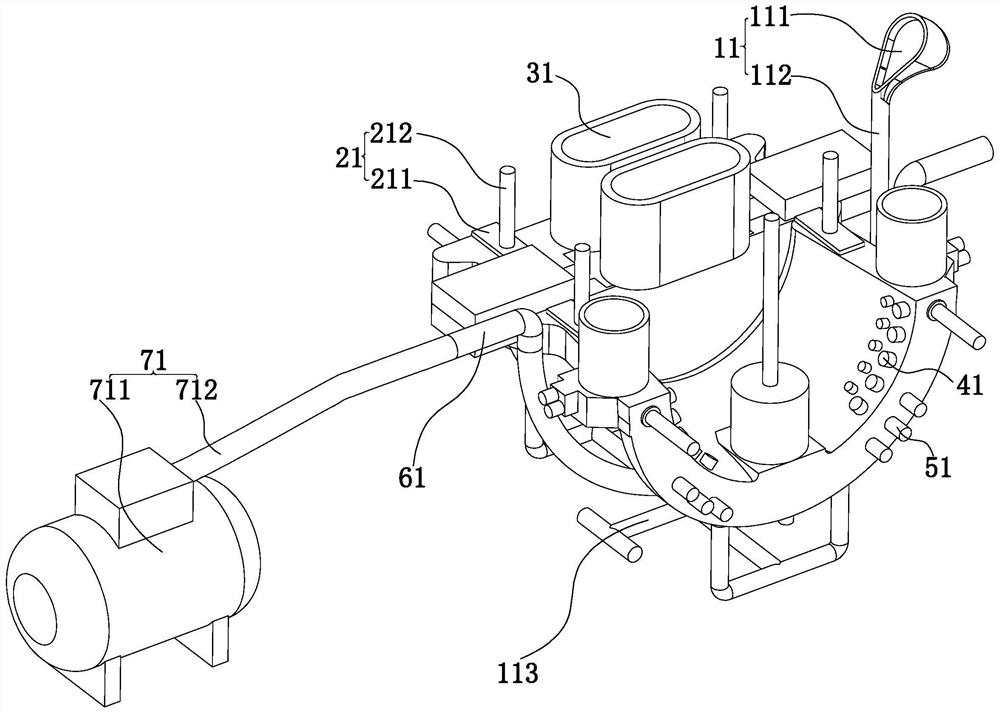

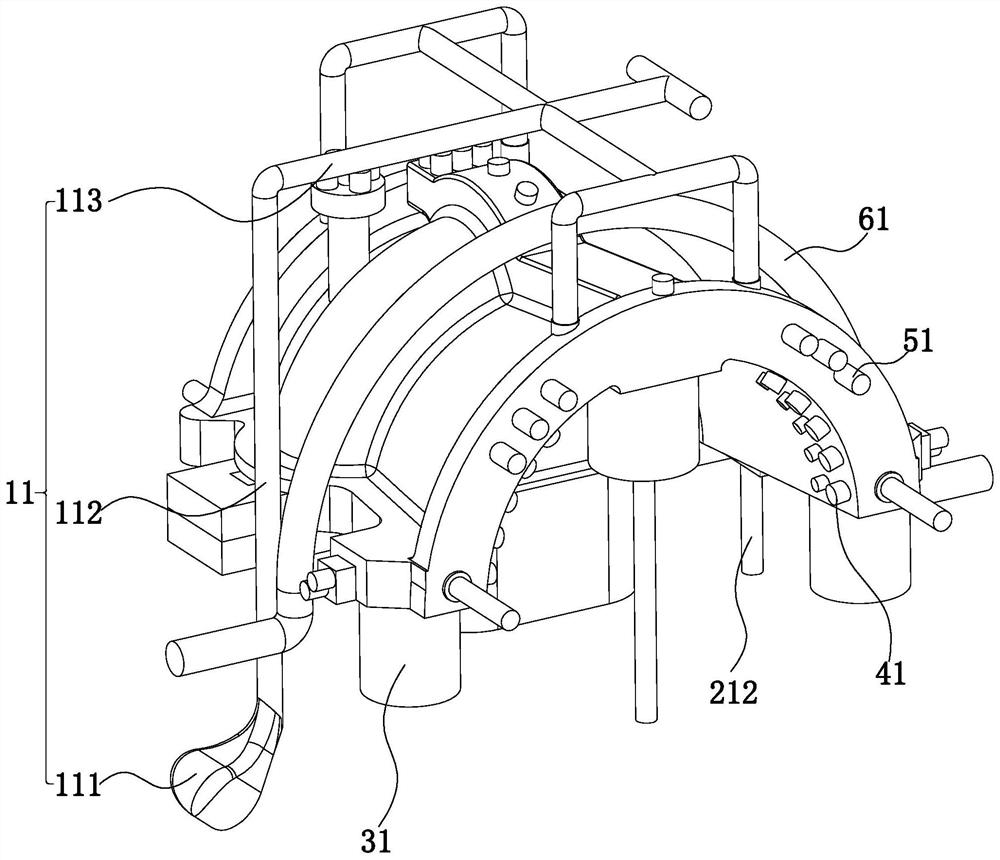

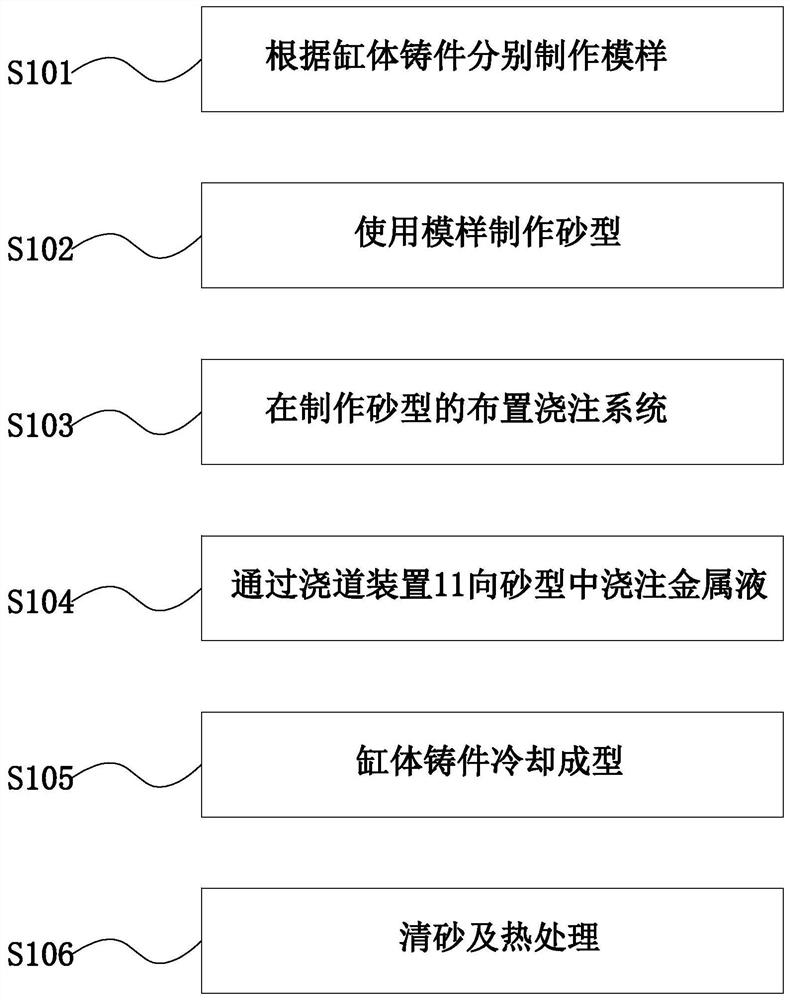

[0043] The following is attached Figure 1-3 The application is described in further detail.

[0044] It can be understood that, in related technologies, steam turbine cylinder castings are divided into upper half castings and lower half castings, which can be poured by integral casting molding. Using integral casting molding requires the use of ingate gating system, and making two After the sand molding, the box casting operation is carried out, and the cylinder body casting is obtained after the pouring is completed. In the pouring process, since the general pouring temperature is above 1500°C, and the end face of the casting is in a semi-closed state, the thick-walled cavity of the sand mold has been burned by high-temperature molten metal for a long time, and the sand mold has a high heating temperature, which is prone to sticking. Problems such as sand and slag inclusions lead to defects in the inner cavity. At this time, it is necessary to remove the defects from the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com