Construction method of stiffened concrete joint overhanging type connecting piece

A construction method and technology for connecting parts, which are applied in the directions of building components, building reinforcements, structural elements, etc., can solve the problems of inability to directly anchor in the column, steel-frame collision, etc., and achieve the effect of simplifying the body and ensuring the compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

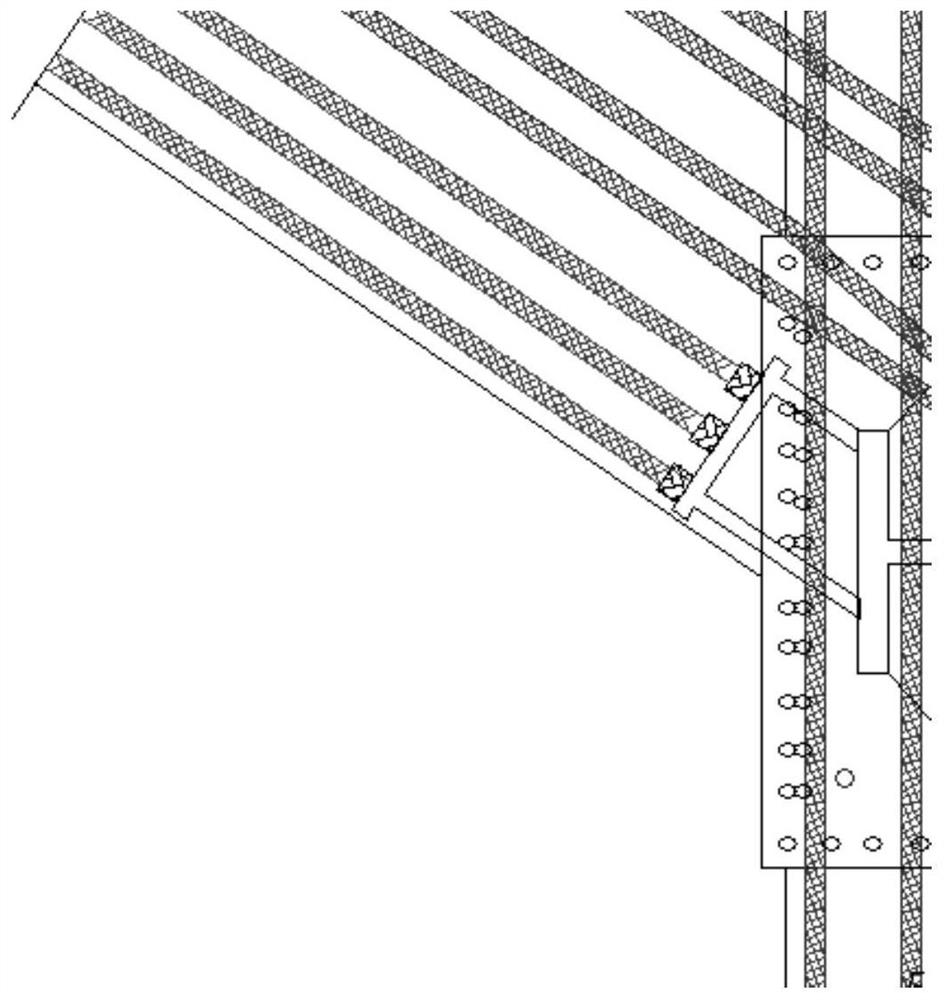

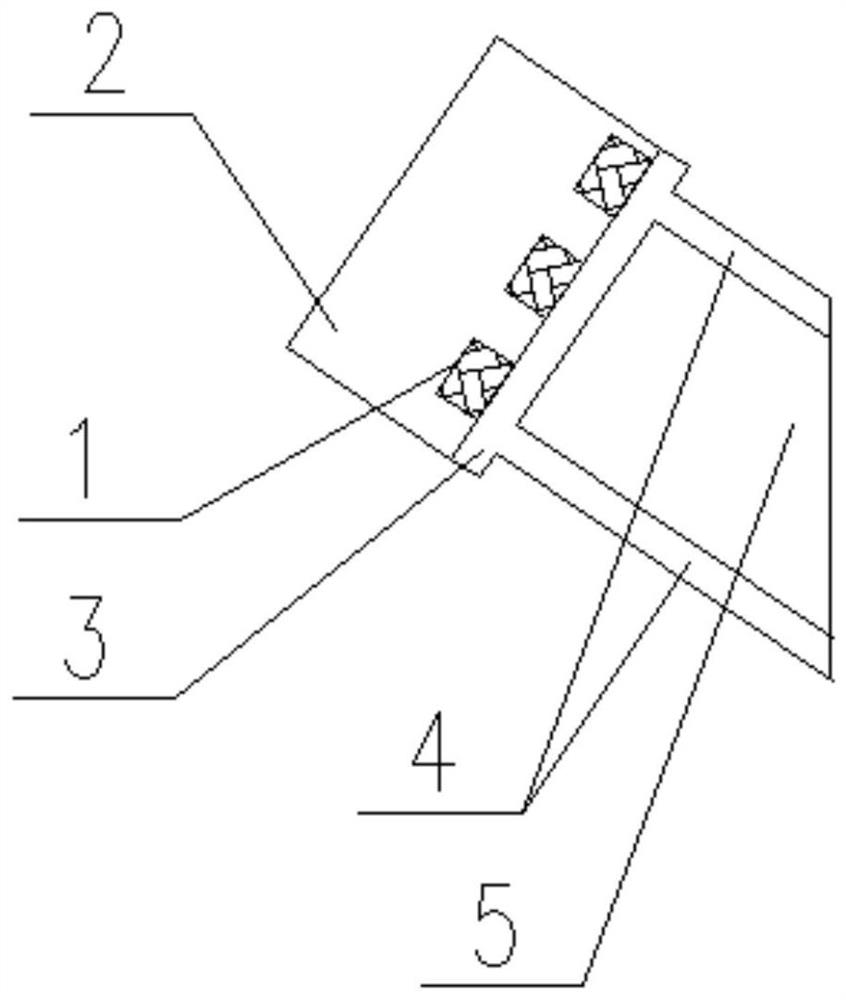

[0032] This embodiment provides a construction method for the extension-type connectors of stiffened concrete joints, which is used to solve the problem that the longitudinal bars in stiffened concrete joints cannot be anchored by traditional methods, that is, when the longitudinal bars of beams are anchored, straight anchors occur. Or the length of the bent anchor cannot meet the requirements of the specification, the angle of the cutting angle of the sleeve welding is not less than or equal to 30°, and the welding length of the gusset plate cannot meet the requirements of the specification. The overhanging connector solves the collision problem between steel bars and steel frames in various situations. The specific solutions are as follows:

[0033] 1. Collision between beam longitudinal reinforcement and variable cross-section steel beam:

[0034] When the height of the shaped steel beam changes, the longitudinal reinforcement of the beam will collide with the shaped steel ...

Embodiment 2

[0048] This embodiment provides a construction method for an overhanging connector, and the specific steps include:

[0049] (1) First, according to the elevation and arrangement of the longitudinal reinforcement, determine whether the longitudinal reinforcement of the beam and the connector are welded or connected with a sleeve. If it is connected with a sleeve, the number and vertical position of the sleeve must be determined;

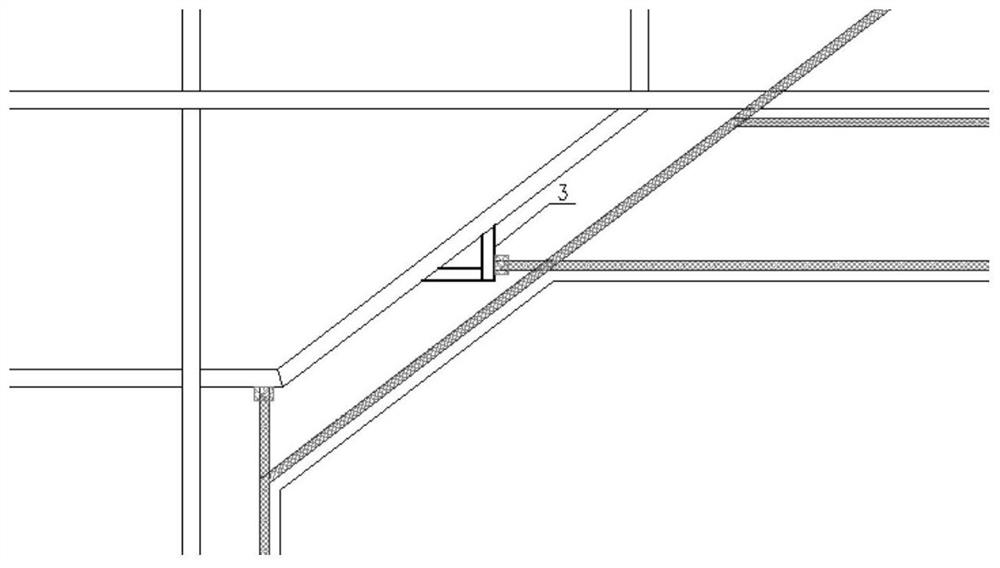

[0050] (2) Secondly, refer to image 3 , if the longitudinal reinforcement of the beam is welded, its spacing shall be determined according to the diameter of the longitudinal reinforcement, and the size of the extended connecting plate 2 for welding shall be determined; if the longitudinal reinforcement of the beam is connected by a sleeve, the diameter of the longitudinal reinforcement shall be determined according to Determine the spacing of the sleeve and the distance to the edge of the gusset plate according to the requirements of the specificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com