BIM 5D-based cast-in-place concrete inclined cylinder construction method and measuring tool

A measuring tool and concrete technology, which is applied in measuring devices, measuring inclination, columns, etc., can solve the problems that the nodes of the construction drawings are not clearly expressed, cannot play the role of guiding the construction line setting and formwork processing, and achieve good economic benefits. The effect of shortening the construction period and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

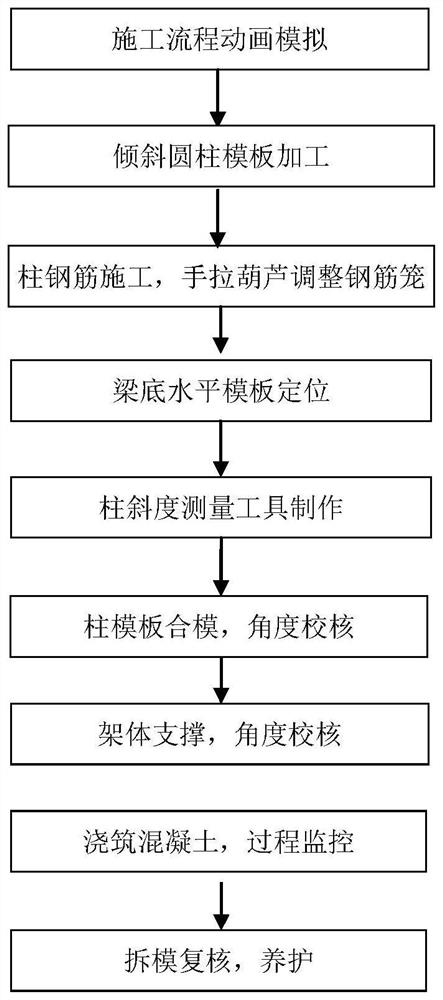

[0031] combined with figure 1 and 2 , a BIM 5D-based construction method for cast-in-place concrete inclined columns. The construction method is carried out in sequence as follows: construction process animation simulation → inclined column formwork processing → column reinforcement construction, chain hoists to adjust the reinforcement cage → beam bottom horizontal formwork positioning → Production of column inclination measuring tools→column formwork clamping, angle check→frame support, angle check→pouring concrete, process monitoring→formwork demolition review, maintenance.

[0032] Use chain hoists to position the cylindrical reinforcement cage; according to the arc opening data of the beam bottom formwork generated by the BIM model, check the size of the beam bottom horizontal formwork on site; according to the BIM model, process the formwork down the length, clamp the cylinder, and use the formwork corners Make column inclination measuring tools, fix and reinforce the f...

Embodiment 2

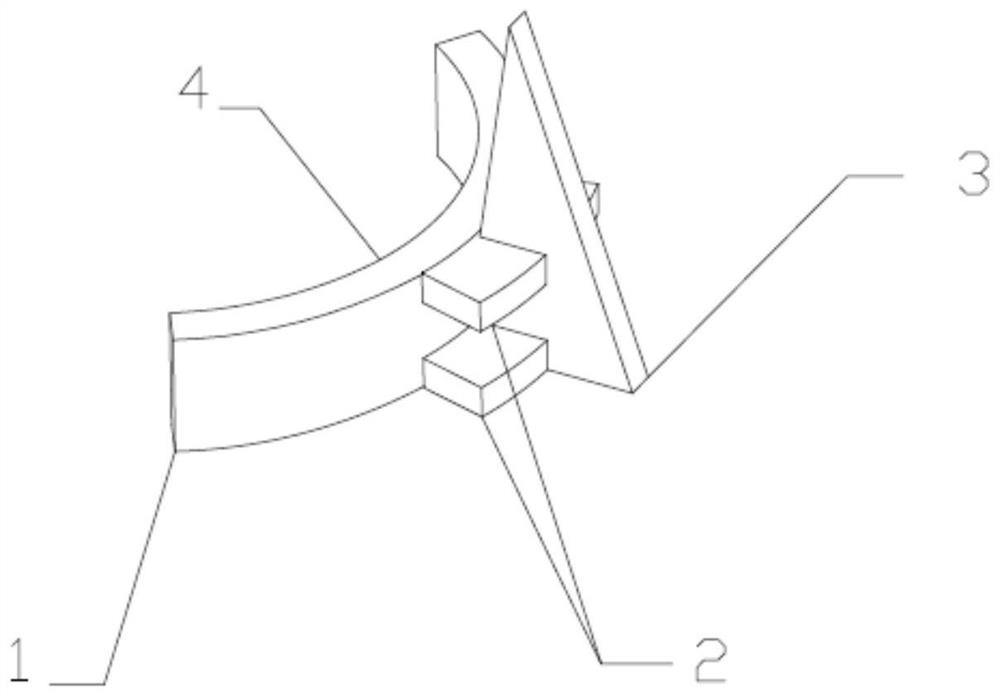

[0044] A measuring tool used in the construction method of an inclined cylinder, comprising a horizontal main body 1 attached to the side wall of the inclined cylinder, connecting parts 2 fixedly connected to the upper and lower ends of the horizontal main body 1, and vertical joints 2 simultaneously clamped to the two connecting parts 2. To the main body 3, the inner side of the vertical main body 3 is used to approach or attach to the side wall of the inclined cylinder; the horizontal main body 1 is provided with an arc-shaped end face 4 that fits the side wall of the cylinder, and the vertical main body 3 is set as a triangular plate shape structure, and the upper end of the vertical main body 3 is located on the upper part of the horizontal main body 1; the connecting part 2 is located at the center of the horizontal main body 1.

[0045] The horizontal main body 1 is configured as a plate structure with an arc-shaped cross-section, the width of the horizontal main body 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com