Open fire cooking range with automatic rotating table top

An automatic rotating and open flame furnace technology, which is applied in the direction of household stoves/stoves, lighting and heating equipment, heating devices, etc., can solve the problems of increased workload, labor cost, easy burning, etc., to achieve accurate fuel heating time, The effect of reducing labor costs and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

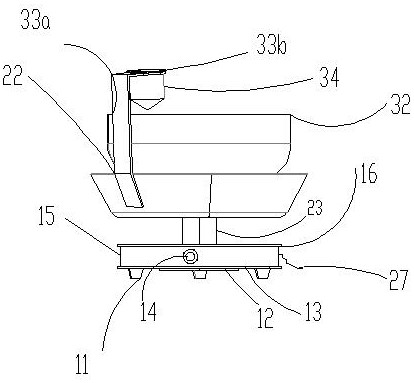

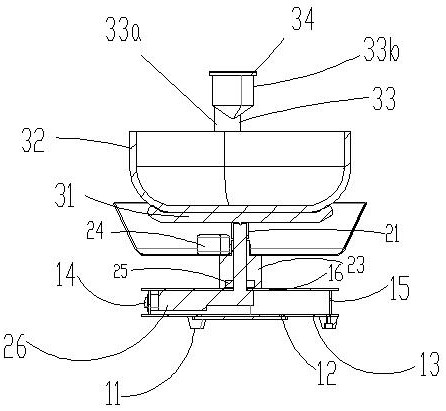

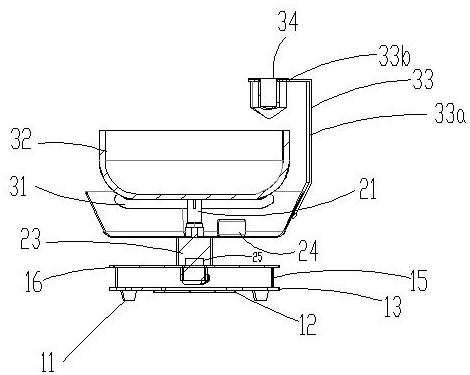

[0023] The reference signs therein are: bearing assembly 1, feet 11, bottom cover 12, lower cover 13, start switch 14, retaining ring 15, upper cover 16, rotating assembly 2, rotating column 21, tray 22, motor 23, biological Fuel block 24, bearing 25, electric control panel 26, power supply 27, latch 28, cooker assembly 3, cooker support 31, cooker 32, oil material box support 33, support handle 33a, support groove 33b, oil material box 34.

[0024] Such as Figure 1 to Figure 5 As shown, the automatic rotating desktop open flame stove includes a furnace body bearing assembly 1 that can be placed on the desktop and a rotating assembly 2 that supports it, wherein: the rotating assembly 2 is composed of an electric control board 26 with a preset control program, and the electric control panel 26. The motor 23 automatically controlled by the boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com