SnS2 microsphere SERS substrate with capillary effect as well as preparation method and application of SnS2 microsphere SERS substrate

A microsphere, na2sno3 3h2o technology, applied in the field of laser Raman spectroscopy and detection, can solve the problems of low sensitivity and unfavorable probe molecule convergence phenomenon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

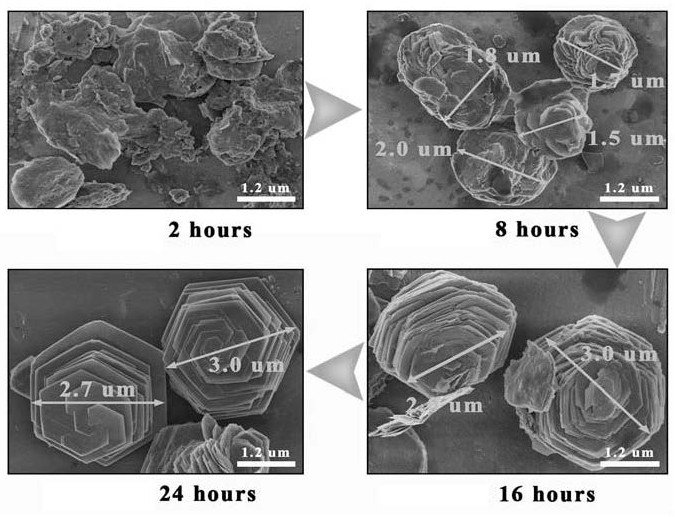

[0058] First, 1.6 g of TTA powder (21.3 mmoL) was added to 55 mL of deionized water, and placed under electromagnetic stirring at a temperature of 60° C. for about 10 minutes to rapidly dissolve the powder to obtain a mixed transparent solution. Then, add 0.8g Na 2 SnO 3 ·3H 2 O powder (3mmoL) was added to the above TTA solution, and electromagnetic stirring was continued at 60°C for about 20 minutes to dissolve the powder quickly and mix uniformly to obtain a precursor solution. Then the above precursor solution was placed in a 100mL PPL-lined hydrothermal reaction kettle, and hydrothermally reacted at 180°C for 24 hours to obtain a brown precipitate, as Figure 11 shown. Finally, the brown precipitate was centrifuged, washed three times with deionized water, and then freeze-dried to obtain brown SnS 2 Microsphere powder.

Embodiment 2

[0060] First, 0.8 g of TTA powder (10.7 mmoL) was added to 55 mL of deionized water, and placed under electromagnetic stirring at a temperature of 60° C. for about 10 minutes to rapidly dissolve the powder to obtain a mixed transparent solution. Then, add 0.4g Na 2 SnO 3 ·3H 2 O powder (1.5mmoL) was added to the above TTA solution, and electromagnetic stirring was continued at 60°C for about 20 minutes to dissolve the powder quickly and mix uniformly to obtain a precursor solution. Then the above precursor solution was placed in a 100mL PPL-lined hydrothermal reaction kettle, and hydrothermally reacted at 180°C for 24 hours to obtain a yellow precipitate, as Figure 11 shown. Finally, the yellow precipitate was centrifuged, washed three times with deionized water, and then freeze-dried to obtain yellow SnS 2 Stacked regular hexagonal nanosheet powder.

Embodiment 3

[0062] Firstly, 2.4 g of TTA powder (32 mmoL) was added into 55 mL of deionized water, and placed under electromagnetic stirring at 60° C. for about 10 minutes to dissolve the powder rapidly, and a mixed transparent solution was obtained. Then, add 1.2g Na 2 SnO 3 ·3H 2 O powder (4.5mmoL) was added to the above TTA solution, and electromagnetic stirring was continued at 60°C for about 20 minutes to dissolve the powder quickly and mix evenly to obtain a precursor solution. Then the above precursor solution was placed in a 100mL PPL-lined hydrothermal reaction kettle, and hydrothermally reacted at 180°C for 24 hours to obtain a dark brown precipitate, as Figure 11 shown. Finally, the dark brown precipitate was centrifuged, washed three times with deionized water, and then freeze-dried to obtain dark brown SnS 2 Micron flower powder formed by intersecting nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com