Cavity structure array assembled by silver nanoparticles as well as preparation method and application of cavity structure array

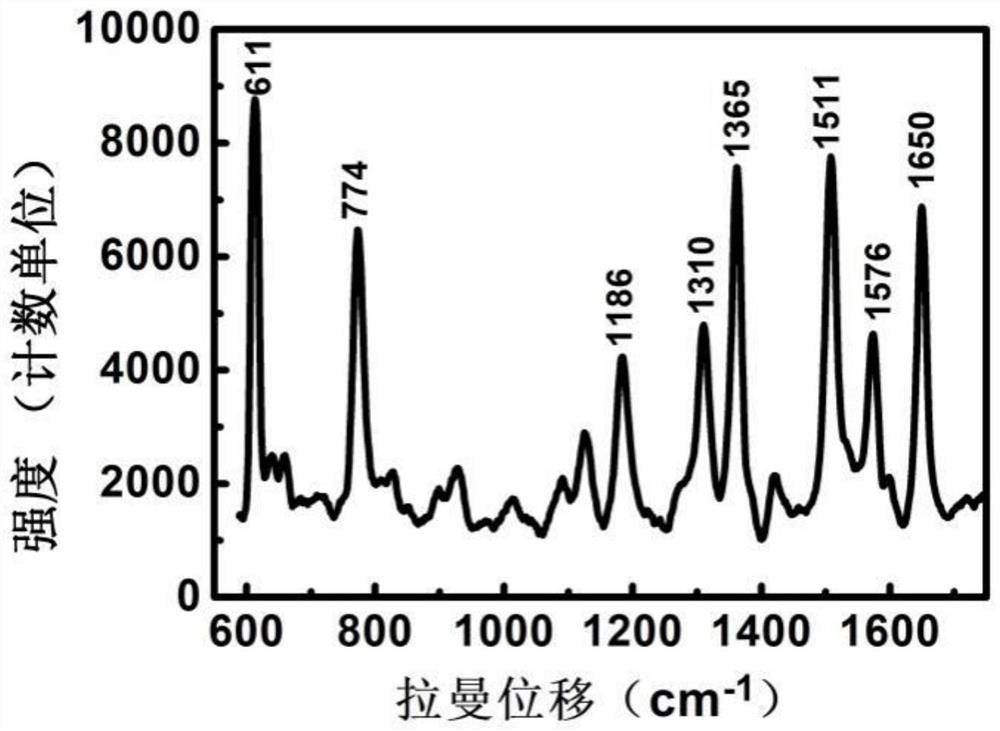

A technology of silver nanoparticles and cavities, which is applied in the field of cavity structure arrays assembled by silver nanoparticles and its preparation, can solve the problems affecting the uniformity and repeatability of SERS signals, complicated preparation steps, etc., and achieves guaranteed batch repeatability. high sensitivity, high SERS sensitivity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] S1, first weigh each group according to the weight ratio of silver nitrate powder, citric acid powder, ethylenediaminetetraacetic acid powder, sodium sulfite powder and dipotassium hydrogen phosphate powder and water in a ratio of 0.1:0.5:0.06:0.3:0.12:50 Dissolve silver nitrate powder, citric acid powder, ethylenediaminetetraacetic acid powder, sodium sulfite powder and dipotassium hydrogen phosphate powder in water in sequence to obtain a mixed solution, and then fully stir the mixed solution to obtain an electrolyte solution;

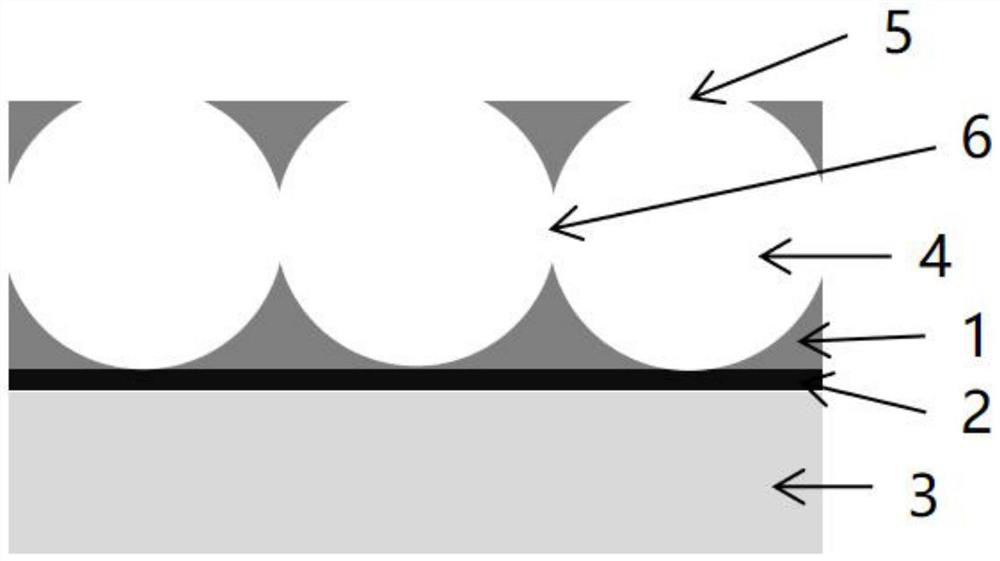

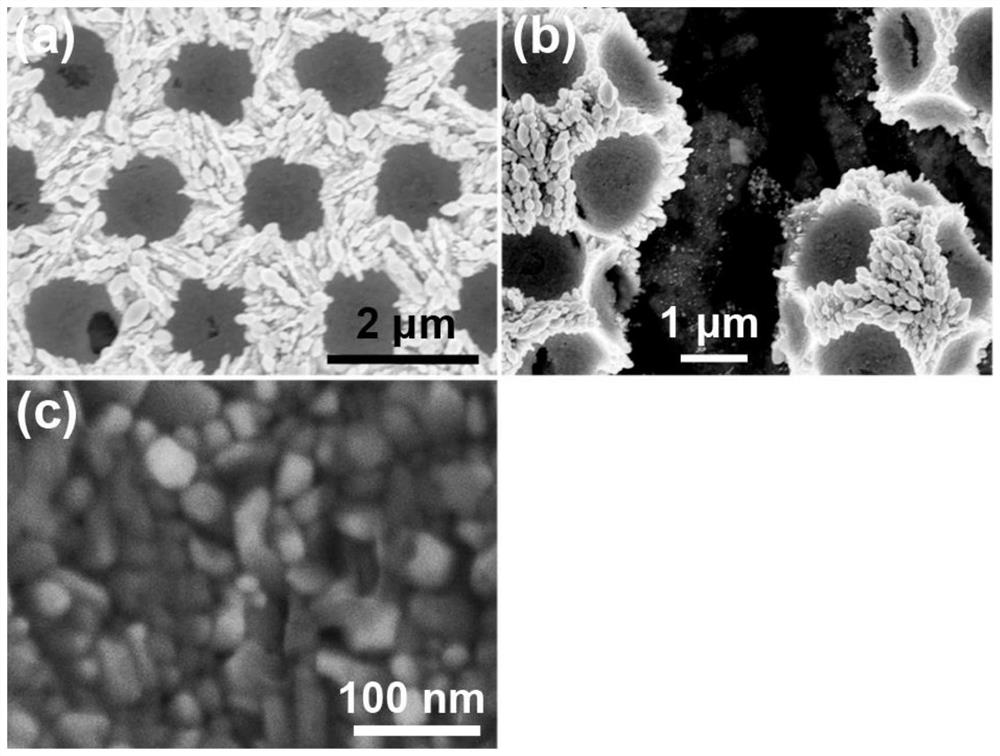

[0037]S2, using an ion sputtering apparatus, sputtering a 15nm thick gold film 2 on a conductive substrate 3, using the liquid surface self-assembly method to prepare a polystyrene microsphere crystal template with a diameter of 500nm and a diameter of 500nm, and then polystyrene The ethylene microsphere crystal template is transferred to the conductive substrate 3, and the conductive substrate 3 covered with the gold film 2 and the polystyrene...

Embodiment 2

[0040] S1, first weigh each group according to the weight ratio of silver nitrate powder, citric acid powder, ethylenediaminetetraacetic acid powder, sodium sulfite powder and dipotassium hydrogen phosphate powder to water in the ratio of 0.12:0.5:0.08:0.5:0.15:48 Dissolve silver nitrate powder, citric acid powder, ethylenediaminetetraacetic acid powder, sodium sulfite powder and dipotassium hydrogen phosphate powder in water in sequence to obtain a mixed solution, and then fully stir the mixed solution to obtain an electrolyte solution;

[0041] S2, using an ion sputtering device, sputtering a 20nm thick gold film 2 on a conductive substrate 3, using the liquid surface self-assembly method to prepare a polystyrene microsphere crystal template with a diameter of 2000nm and a diameter of 2000nm, and then polystyrene The ethylene microsphere crystal template is transferred to the conductive substrate 3, and the conductive substrate 3 covered with the gold film 2 and the polystyre...

Embodiment 3

[0044] S1, first weigh each group according to the weight ratio of silver nitrate powder, citric acid powder, ethylenediaminetetraacetic acid powder, sodium sulfite powder and dipotassium hydrogen phosphate powder to water in the ratio of 0.15:1.1:0.1:0.5:0.2:52 Dissolve silver nitrate powder, citric acid powder, ethylenediaminetetraacetic acid powder, sodium sulfite powder and dipotassium hydrogen phosphate powder in water in sequence to obtain a mixed solution, and then fully stir the mixed solution to obtain an electrolyte solution;

[0045] S2, using an ion sputtering device, sputtering a 30nm thick gold film 2 on a conductive substrate 3, using the liquid surface self-assembly method to prepare a polystyrene microsphere crystal template with a diameter of 5000nm and a diameter of 5000nm, and then polystyrene The ethylene microsphere crystal template is transferred to the conductive substrate 3, and the conductive substrate 3 covered with the gold film 2 and the polystyrene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com