Color plating device for aerospace mold production

An aerospace and mold technology, applied in the direction of spraying devices, devices for coating liquid on the surface, spray booths, etc., can solve the problems of inconvenient use, coating thickness and uniformity control, etc., and achieve pollution prevention, good spraying effect, The effect of high design selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

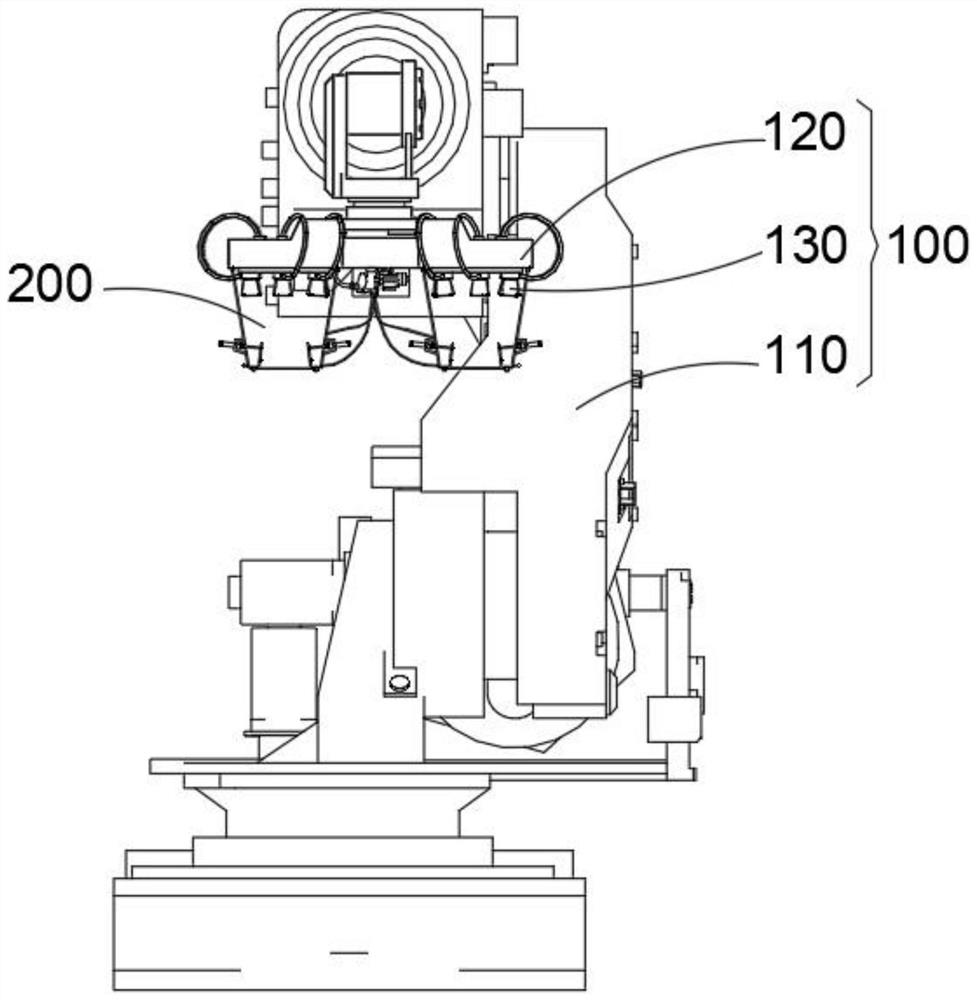

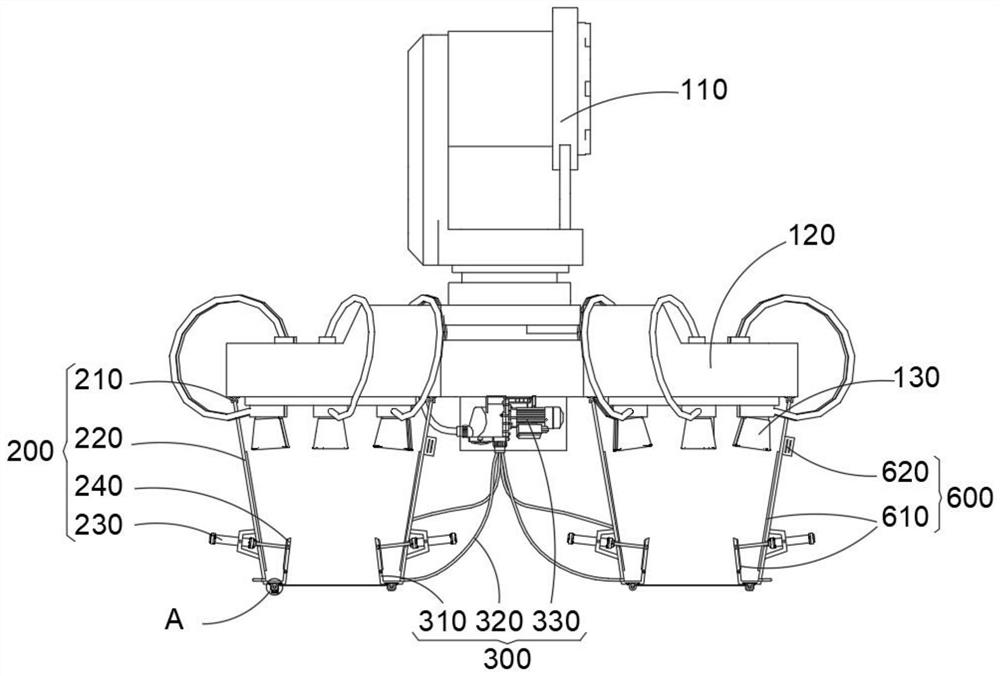

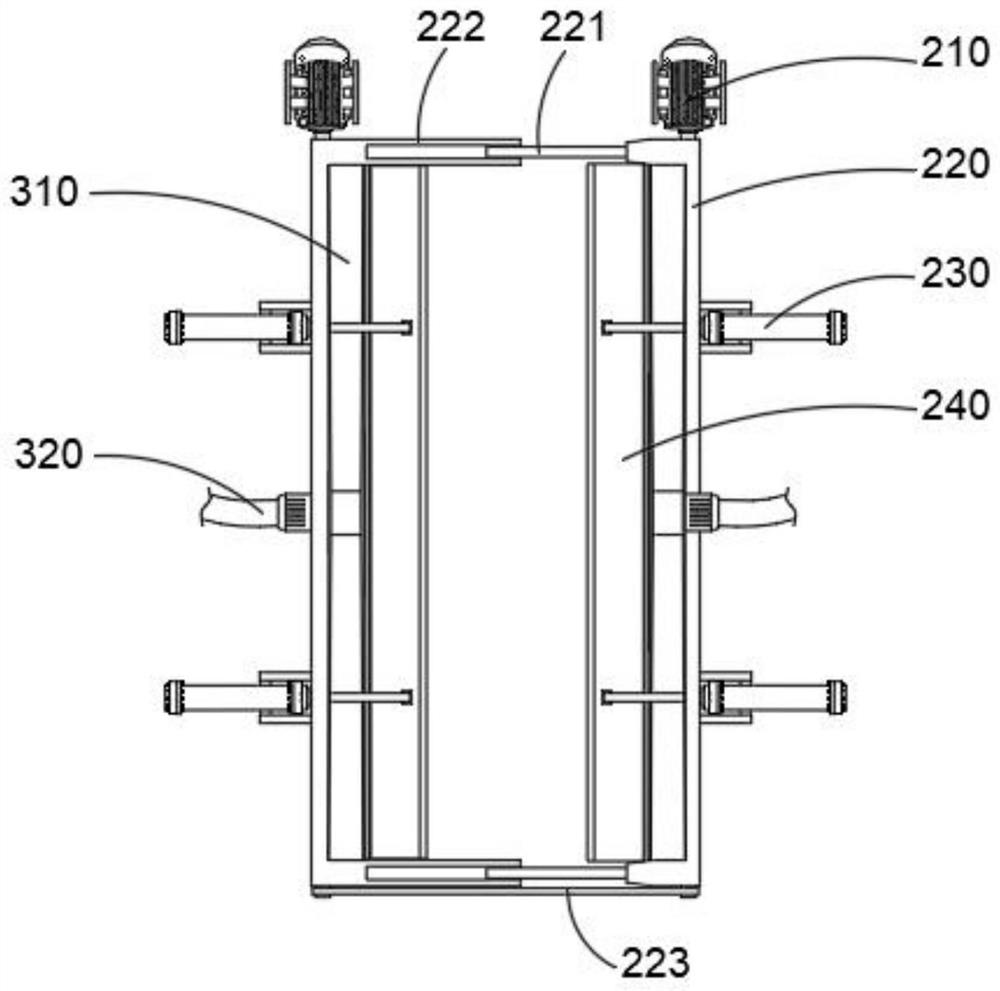

[0044] combine Figure 1-7As shown, the color plating device for aerospace mold production provided by the present invention includes: a spraying mechanism 100, an adjustment mechanism 200, a recycling mechanism 300, a pattern coating mechanism 400, a drying mechanism 500 and a heating mechanism 600, and the spraying mechanism 100 includes a The mechanical arm 110 of the spraying operation, the installation platform 120 connected to the driving end of the mechanical arm 110, and the spraying head 130 installed on the installation platform 120 for spraying materials. The head 130 is an adjustable spray head, which is convenient for different colors of paint to generate the required colors. The position and orientation of the spray head 130 can be automatically controlled through the mechanical arm 110, which is convenient for the overall spraying of the model, and the installation platform 120 is used to accommodate multiple groups of spray heads 130 The hollow plate structure ...

Embodiment 2

[0052] combine figure 2 As shown, on the basis of Embodiment 1, the heating mechanism 600 is arranged on the adjustment baffle 220 and the liquid storage tank 310 for heating and collecting the paint. The heating mechanism 600 includes The heating patch 610 on the inner wall and the heater 620 electrically connected to the heating patch 610, through the heating mechanism 600, the paint to be in contact with the adjustment baffle 220 can fall on the heating patch 610, and the heater 620 is used to control the heating patch 620. The sheet 610 continues to generate heat, so that the paint after contact will not solidify, but flows into the interior of the liquid storage tank 310 along the heating patch 610, further improving the collection effect of the paint. Of course, the interior of the liquid storage tank 310 can also be provided with The heating patch 610 has the same structure as the heating element to prevent the paint from solidifying before being discharged, which is m...

Embodiment 3

[0055] combine figure 2 and 6 As shown, in the above embodiment, the drying mechanism 500 is installed on the coating mechanism 400 to pre-dry the spraying position, and the surface of the model after spraying can be dried by the heating mechanism 600, so that the paint can be dried quickly, preventing Contamination and deformation caused by foreign objects falling on it or tilting movement to ensure the stability of the sprayed surface.

[0056] Specifically, the drying mechanism 500 includes a box seat 510 arranged outside the winding drum 430, a drying heater 520 installed on the box seat 510 for radiant heating, and a material baffle plate connected to the box seat 510 and located inside the drying heater 520. 530, the box base 510 is used to protect the structure of the reel 430 on the coating mechanism 400. It is a detachable structure, which is convenient for the setting of the drying mechanism 500 during installation. The drying heater 520 is a radiation dryer, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com