Heat dissipation system for mine car

A heat dissipation system and mining car technology, which is applied in the direction of mining cars, transport passenger cars, railway car body parts, etc., can solve the problems of complex air duct design and layout of the whole vehicle, large space occupied by the air cooling system, and long distances between components. Achieve the effect of convenient design and assembly, low cost and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

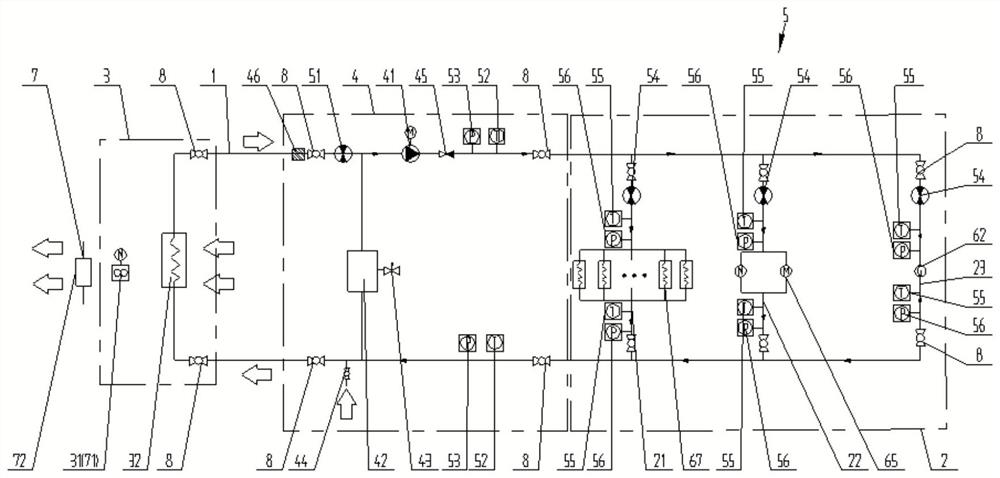

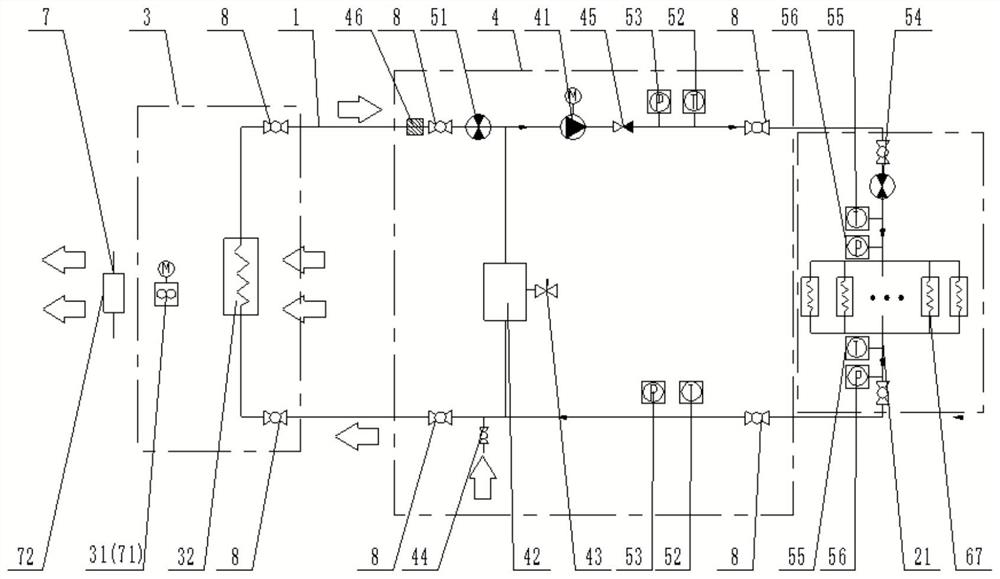

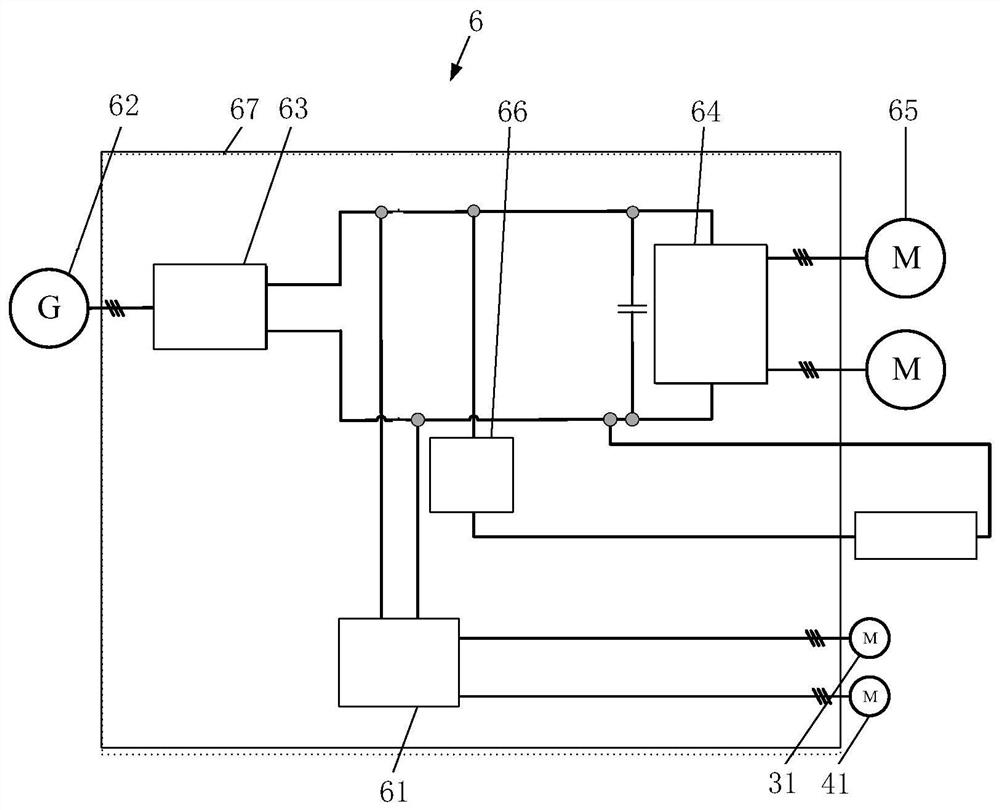

[0029] Such as figure 1 As shown, the heat dissipation system for mine vehicles in this embodiment includes a circulating heat dissipation channel 1 , a traction system cooling unit 2 , a water cooling unit 3 and a control and protection unit 4 . Among them, the water cooling unit 3 and the traction system cooling unit 2 are connected in series through the circulating heat dissipation channel 1, and the water cooling unit 3 performs water cooling on the high-temperature coolant passing through the traction system cooling unit 2; the control and protection unit 4 is arranged on the water cooling unit 3 and the traction system cooling unit 2 Between, used to control and protect the entire cooling system.

[0030] The present invention changes the structural form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com