Raw material filtering device for supercritical extraction pretreatment

A filtration device and pretreatment technology, applied in the field of raw material filtration devices for supercritical extraction pretreatment, can solve the problems of filter screen clogging, reduced filtration effect, poor filtration effect, etc., so as to reduce the possibility of clogging and enhance the filtration effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

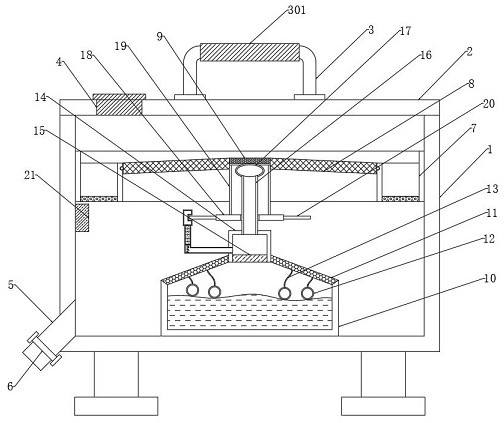

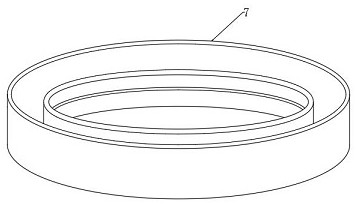

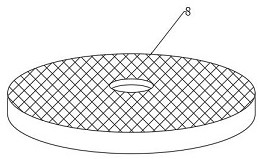

[0033] see Figure 1-4 , a raw material filtering device for supercritical extraction pretreatment, comprising a filter cartridge 1, the lower end of the filter cartridge 1 is fixedly connected with two pairs of left and right symmetrical support legs, the outer end of the filter cartridge 1 is rotatably connected with a sealing cover plate 2, and the sealing cover The upper end of the plate 2 is fixedly connected with a handle 3, and the upper end of the sealing cover plate 2 is dug with a feed inlet, and a sealing plug 4 is connected to the inside of the feed inlet, and the outer end of the filter cartridge 1 is fixedly connected with a discharge pipe 5, and the discharge pipe 5 communicates with the inside of the filter cartridge 1, a valve 6 is installed on the outer end of the discharge pipe 5, an annular collection frame 7 is fixedly connected to the inner wall of the filter cartridge 1, and an annular filter screen 8 is slidingly connected between the inner walls of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com