Intelligent raw material pretreatment equipment for environment-friendly hollow brick production

A technology of hollow bricks and pretreatment, which is applied in the direction of mixers with rotating stirring devices, dissolution, magnetic separation, etc., which can solve the problems of large reconstruction costs, limited space, and reduced energy consumption, and achieve convenient disassembly and replacement , easy to clean, high effect of iron removal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further illustrated by the following examples.

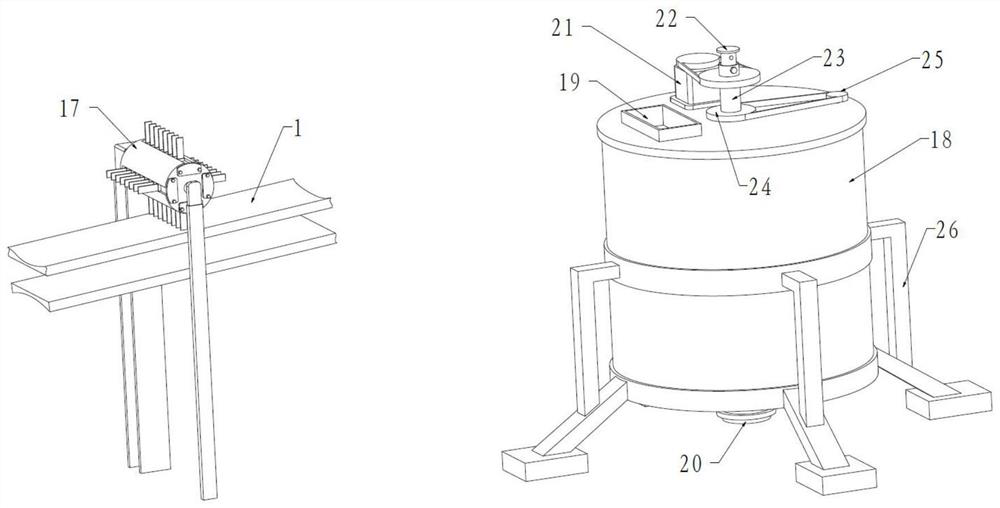

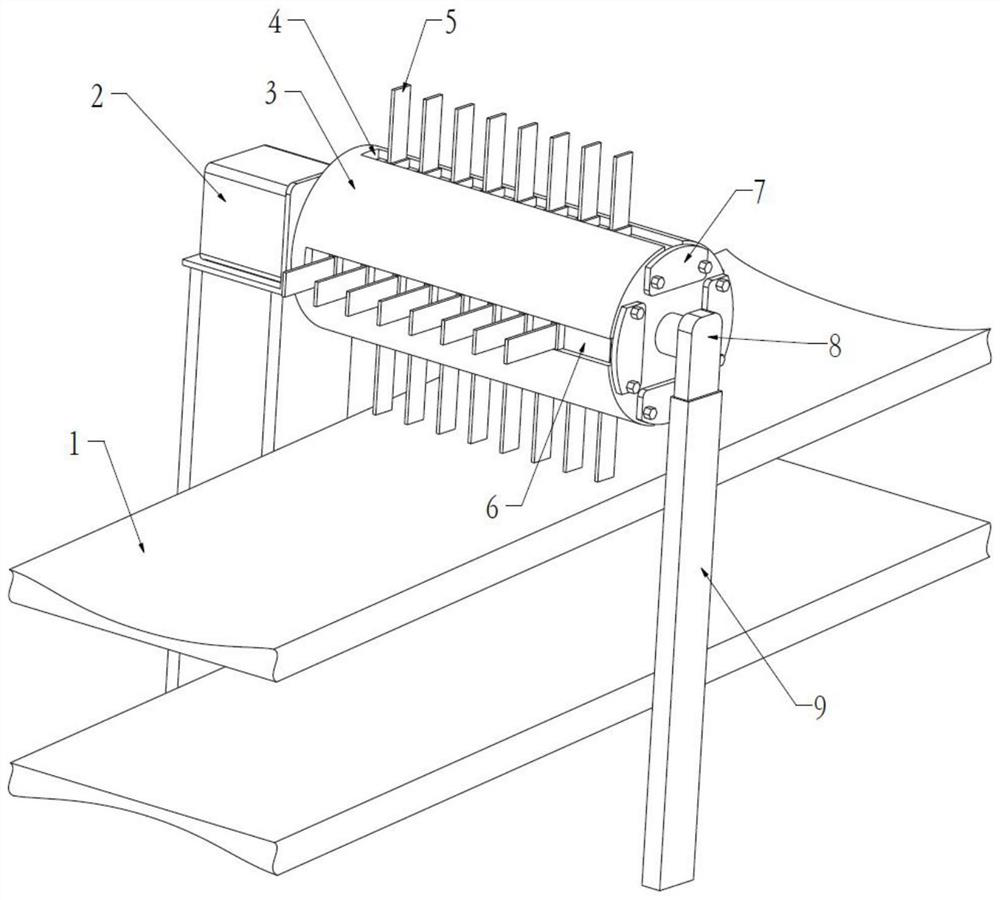

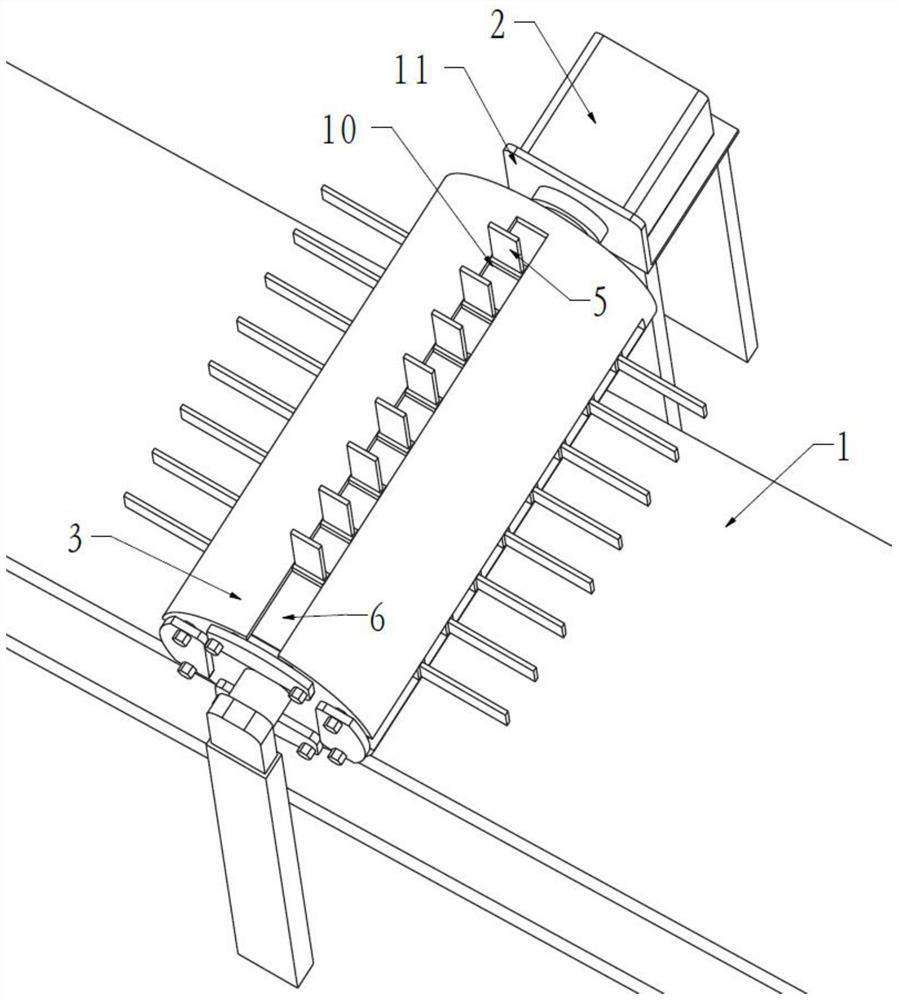

[0033] The raw material intelligent pretreatment equipment for the production of environmentally friendly hollow bricks, including a conveyor belt 1, the conveyor belt 1 is connected to a mixing cylinder 18, the mixing cylinder 18 is supported by a bracket 26, the top cover of the mixing cylinder 18 is provided with a feed port 19 and the bottom is opened There is a discharge port 20, and an iron removal assembly 17 is arranged on the top of the conveyor belt 1. The iron removal assembly 17 includes a rotating part 3, and an annular array on the rotating part 3 is provided with mounting holes 16, and the surface of the rotating part 3 is located in the mounting hole 16. A notch 4 is opened at the place, and an iron adsorption mechanism is movably arranged in the installation hole 16. The iron adsorption mechanism includes a base 6, and the base 6 is movably arranged in the installation hole 16, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com