Indium particle preparation device and method

A preparation device and particle technology, which is applied in the field of metal particle preparation, can solve the problems of particle deformation, adhesion, and affecting the quality of metal particle preparation, and achieve the effect of ensuring the preparation quality and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

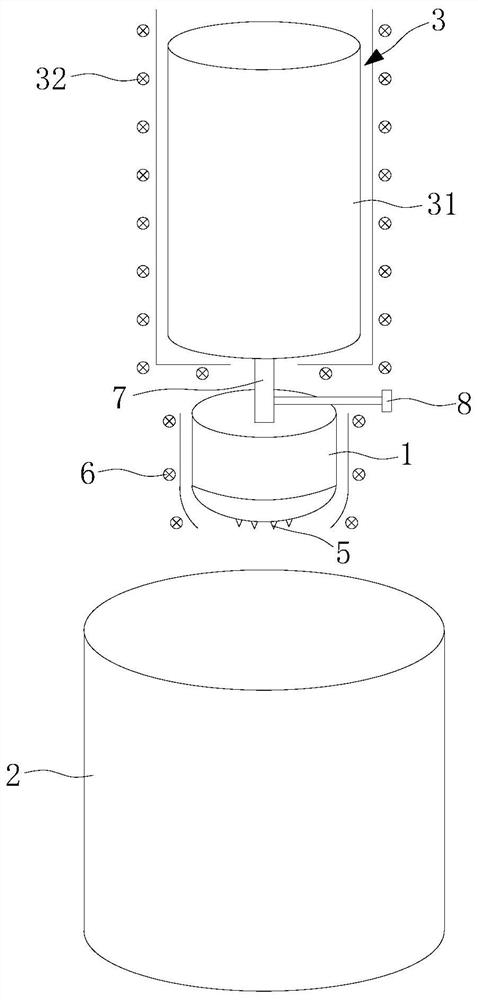

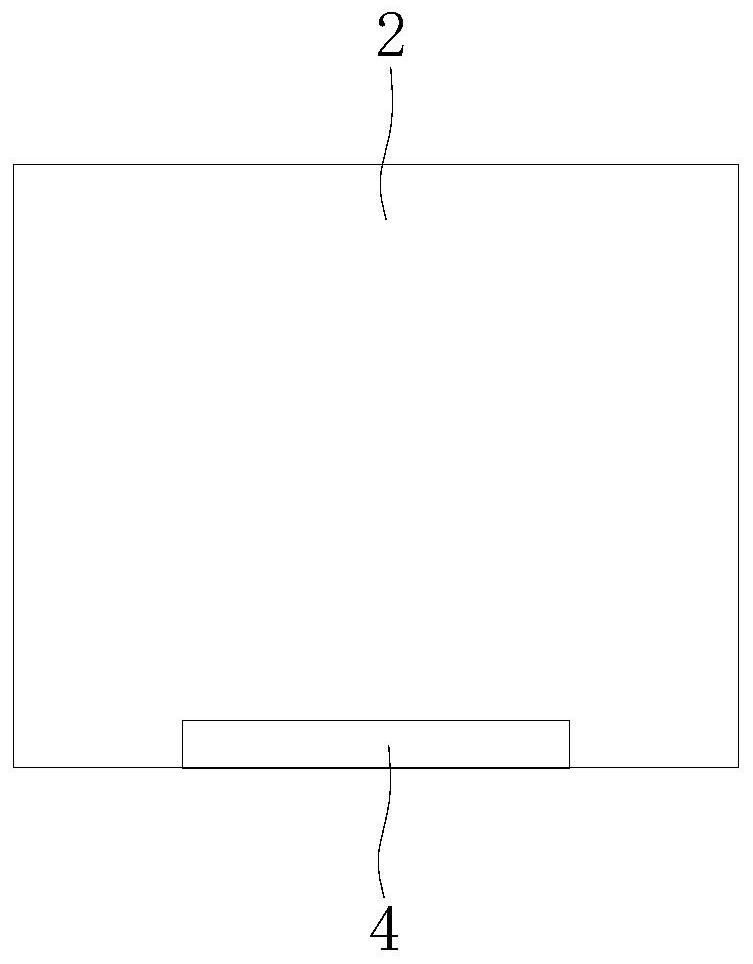

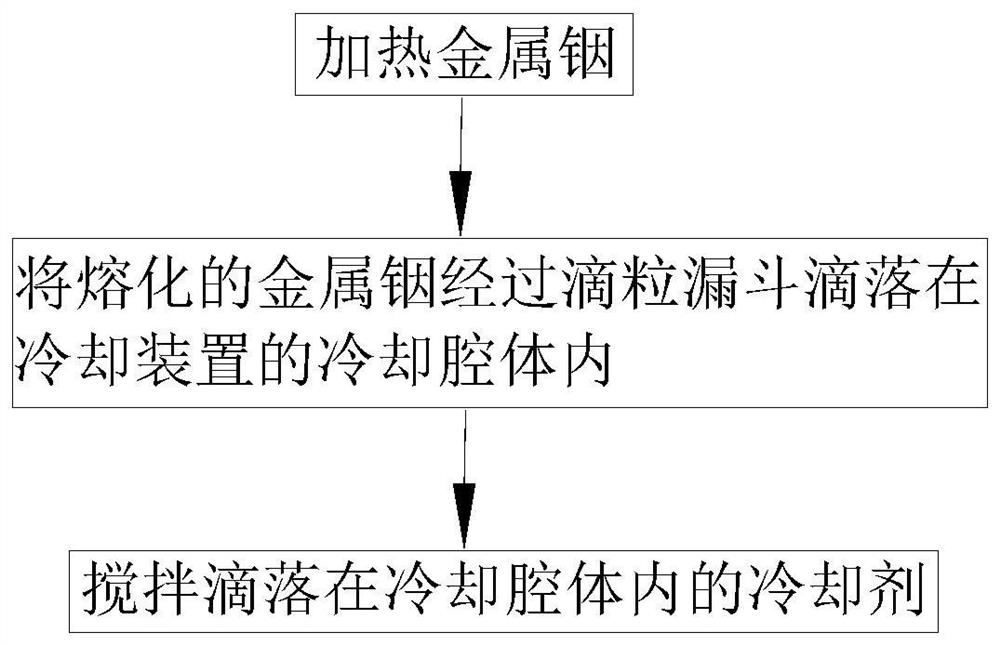

[0040] Such as Figure 1 to Figure 2 As shown, a device for preparing indium particles according to a preferred embodiment of the present invention includes a melting device 3 , a dropping funnel 1 and a cooling device 2 . The melting device 3 has a melting chamber; the melting chamber has a first feed end and a first discharge end. The dropping funnel 1 has a drop cavity; the drop cavity has a second discharge end and a second feed end communicated with the first discharge end. The cooling device 2 is arranged below the dropping funnel 1; the cooling device 2 has a cooling chamber; the cooling chamber has a third feed end connected to the second discharge end; the cooling agent is housed in the cooling chamber; There are 4 mixers.

[0041] Based on the above technical solution, during the preparation process, the strip-shaped metal indium is put into the melting chamber. This application has no specific requirements on the purity of metal indium. In this embodiment, the p...

Embodiment 2

[0067] Pure water with a temperature of 15° C. is added into the cooling device 2 and the liquid level is 600 mm. Add 1 kg of 6N metal indium into the melting device 3, and preheat the dropping funnel 1 to 170°C, and heat the melting device 3 to 195°C. After the metal indium is completely melted, continue heating for 10 minutes, and open the control valve at the bottom of the melting device 3 8. The molten metal indium flows into the dropping funnel 1. The flow rate is controlled by the control valve 8 to keep the molten liquid level at a fixed height. The inner diameter of the second discharge end is 0.8 mm, and the height from the second discharge end to the liquid level of the coolant is 80 mm. Metal indium droplets are dropped into pure water for rapid cooling And rotate with the magnetic stirring bar to avoid sticking. After the droplet is completed, the indium particles in the pure water are taken out and dried for vacuum packaging.

[0068] The surface of the prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com