Double-component wall surface structure crack repairing material and use method thereof

A repair material and two-component technology, applied in the field of crack repair, can solve problems such as high cost, cracks in the decorative layer of the wall, and incomplete repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

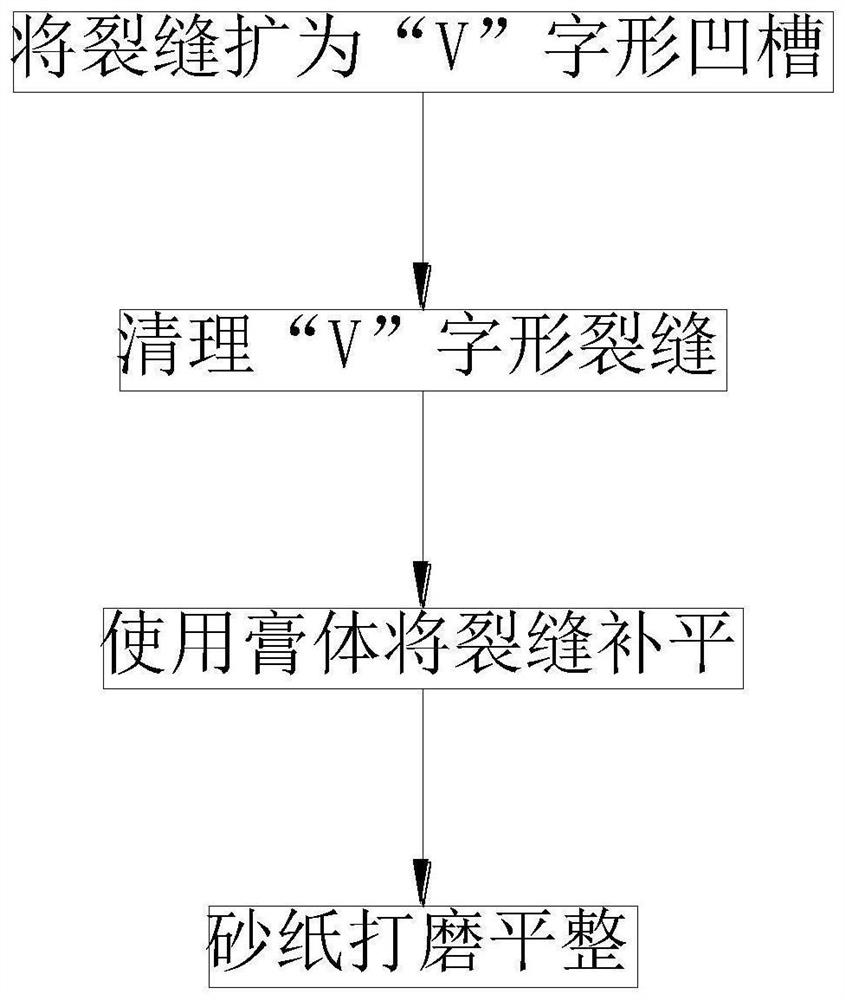

Method used

Image

Examples

Embodiment 1

[0031] The two-component wall structure agent is divided into two components, A and B. The A component is a viscous liquid, and the B component is a powder solid. The A and B components are prepared according to the ratio of 0.8:1 and stirred into a uniform paste. Body use.

[0032] Further, the components of component A include styrene-acrylic polymer emulsion, film-forming aids, dispersants, wetting agents, defoamers, bactericides, and deionized water.

[0033] Furthermore, the main components of component B are white cement, quartz sand, heavy calcium powder, polypropylene fiber, latex powder, and water-retaining thickener.

[0034] Further, the above-mentioned components A and B were added to the mortar stirring and dispersing equipment at the same time, and the stirring was started, and the stirring time was 30 minutes, and the stirring temperature was 30°C.

[0035] Further, the styrene-acrylic polymer emulsion contains highly flexible polymer particles, which form a co...

Embodiment 2

[0046] The two-component wall structure agent is divided into two components, A and B. The A component is a viscous liquid, and the B component is a powder solid. The A and B components are formulated according to the ratio of 1:1 and stirred into a uniform paste. Body use.

[0047] Further, the components of component A include styrene-acrylic polymer emulsion, film-forming aids, dispersants, wetting agents, defoamers, bactericides, and deionized water.

[0048] Furthermore, the main components of component B are white cement, quartz sand, heavy calcium powder, polypropylene fiber, latex powder, and water-retaining thickener.

[0049] Further, the above-mentioned components A and B were added to the mortar stirring and dispersing equipment at the same time, and the stirring was started, and the stirring time was 40 minutes, and the stirring temperature was 40°C.

[0050] Further, the styrene-acrylic polymer emulsion contains highly flexible polymer particles, which form a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com