A low-alloyed, easy-to-extrude, easy-to-recycle aluminum alloy and its preparation process

A preparation process and technology for aluminum alloys, which are applied in the field of low-alloyed, easy-to-extrude and easy-to-recycle 6-series aluminum alloys, can solve the problems of increased selection cost of recycled aluminum, difficulty in blending alloying elements, and increased carbon emissions in the industrial chain, so as to reduce degradation risk, yield strength improvement, and tensile strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

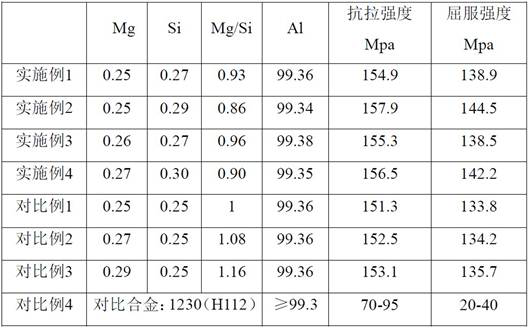

Examples

Embodiment 1

[0037] A low-alloyed, easy-to-extrude, easy-to-recycle aluminum alloy is prepared through the following steps:

[0038] 1) Adjust the alloy composition and prepare aluminum alloy raw materials according to the following weight percentages: Mg 0.25%, Si 0.27%, Mg / Si=0.93, Fe: ≤0.10%, Cu ≤0.001%, Mn ≤0.001%, Cr ≤0.001%, Zn ≤0.01%, Ti 0.01%, B0.004%, V≤0.005%, single impurity ≤0.005%, total impurity ≤0.01%, Al 99.36%.

[0039] 2) For casting aluminum alloy ingots, add the prepared aluminum alloy raw materials into the melting furnace to melt into molten aluminum, and stir them evenly with electromagnetic stirring equipment, and use refining agents for refining and degassing to ensure that they stand still for more than 30 minutes to ensure The coarse compound formed is fully precipitated, and then the impurities in the molten aluminum are filtered through a ceramic filter plate, and then the molten aluminum is cast into an aluminum alloy ingot.

[0040] 3) Homogenization treatme...

Embodiment 2

[0044] A low-alloyed, easy-to-extrude, easy-to-recycle aluminum alloy is prepared through the following steps:

[0045] 1) Adjust the alloy composition and prepare the aluminum alloy raw materials according to the following weight percentages: Mg 0.25%, Si 0.29%, Mg / Si=0.86, Fe: ≤0.10%, Cu ≤0.001%, Mn ≤0.001%, Cr ≤0.001%, Zn ≤0.01%, Ti 0.015%, B0.005%, V≤0.005%, single impurity ≤0.005%, total impurity ≤0.01%, Al 99.34%.

[0046] 2) For casting aluminum alloy ingots, add the prepared aluminum alloy raw materials into the melting furnace to melt into molten aluminum, and stir them evenly with electromagnetic stirring equipment, and use refining agents for refining and degassing to ensure that they stand still for more than 30 minutes to ensure The coarse compound formed is fully precipitated, and then the impurities in the molten aluminum are filtered through a ceramic filter plate, and then the molten aluminum is cast into an aluminum alloy ingot.

[0047] 3) Homogenization tr...

Embodiment 3

[0051] A low-alloyed, easy-to-extrude, easy-to-recycle aluminum alloy is prepared through the following steps:

[0052] 1) Adjust the alloy composition and prepare the aluminum alloy raw materials according to the following weight percentages: Mg 0.26%, Si 0.27%, Mg / Si=0.96, Fe: ≤0.10%, Cu ≤0.001%, Mn ≤0.001%, Cr ≤0.001%, Zn ≤0.01%, Ti 0.013%, B0.003%, V≤0.005%, single impurity ≤0.005%, total impurity ≤0.01%, Al 99.38%.

[0053] 2) For casting aluminum alloy ingots, add the prepared aluminum alloy raw materials into the melting furnace to melt into molten aluminum, and stir them evenly with electromagnetic stirring equipment, and use refining agents for refining and degassing to ensure that they stand still for more than 30 minutes to ensure The coarse compound formed is fully precipitated, and then the impurities in the molten aluminum are filtered through a ceramic filter plate, and then the molten aluminum is cast into an aluminum alloy ingot.

[0054] 3) Homogenization tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com